Page 4 - 頂針

P. 4

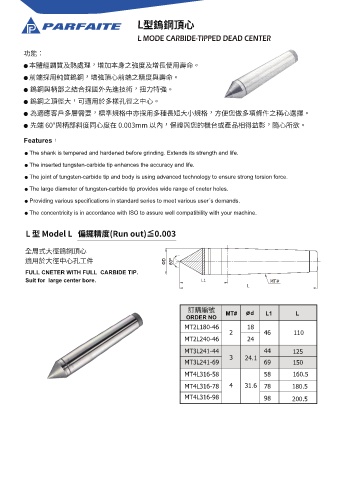

L型鎢鋼頂心

L MODE CARBIDE-TIPPED DEAD CENTER

功能:

● 本體經調質及熱處理,增加本身之強度及增長使用壽命。

● 前端採用純質鎢鋼,增強頂心前端之精度與壽命。

● 鎢鋼與柄部之結合採國外先進技術,扭力特強。

● 鎢鋼之頂徑大,可適用於多樣孔徑之中心。

● 為適應客戶多層需要,標準規格中亦採用多種長短大小規格,方便您做多項條件之稱心選擇。

● 先端 60°與柄部斜度同心度在 0.003mm 以內,保證與您的機台或產品相得益彰,隨心所欲。

Featuresj

● The shank is tempered and hardened before grinding. Extends its strength and life.

● The inserted tungsten-carbide tip enhances the accuracy and life.

● The joint of tungsten-carbide tip and body is using advanced technology to ensure strong torsion force.

● The large diameter of tungsten-carbide tip provides wide range of cneter holes.

● Providing various specifications in standard series to meet various user´s demands.

● The concentricity is in accordance with ISO to assure well compatibility with your machine.

L 型 Model L 偏擺精度(Run out)≦0.003

全周式大徑鎢鋼頂心

適用於大徑中心孔工件

FULL CNETER WITH FULL CARBIDE TIP.

Suit for large center bore.

訂購編號 MT# ød L1 L

ORDER NO

MT2L180-46 18

2 46 110

MT2L240-46 24

160.5

MT3L241-44 14 31.6 58 125

44

3 24.1

MT3L241-69 69 150

MT4L316-58 58 160.5

MT4L316-78 4 31.6 78 180.5

MT4L316-98 98 200.5