Page 15 - 普慧2020刀把(電子書版)

P. 15

刀把特性比較表

Comparison Table

精度 夾持力 夾持範圍 高速加工性 成本

Run-Out Clamping Force Clamping Range HSC Cost

HY Hydraulic Chuck

油壓刀把 Ù3µ 3-32mm High 高

CR Standard Shrink Fit Chuck Holder:Middle

刀把:中等

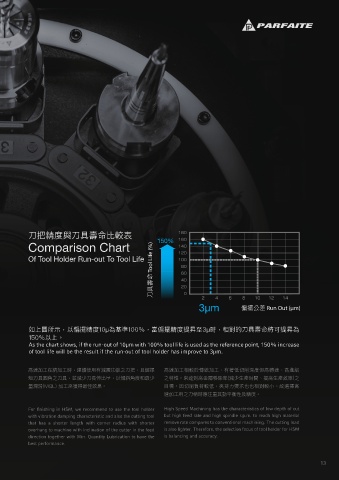

標準型熱縮刀把 Ù3µ 4-32mm Equipment:High 刀把精度與刀具壽命比較表

週邊:高

Comparison Chart

SR Slim Type Shrink Fit Chuck Holder:Middle Of Tool Holder Run-out To Tool Life

刀把:中等

細長型熱縮刀把 Ù3µ 4-12mm Equipment:High 刀具壽命 Tool Life (%) 150%

週邊:高

HER HER Collet Chuck

HER 筒夾式刀把 Ù5µ 1-20mm Fair 合理

3µm 偏擺公差 Run Out (µm)

PFK PFK Collet Chuck 1-25mm

PFK 筒夾式刀把 Ù5µ Fair 合理 如上圖所示,以偏擺精度10μ為基準100%,當偏擺精度提昇至3μ時,相對的刀具壽命將可提昇為

150%以上。

As the chart shows, if the run-out of 10µm with 100% tool life is used as the reference point, 150% increase

ERB / ERBR ER Collet Chuck of tool life will be the result if the run-out of tool holder has improve to 3µm.

( Ball Bearing Nut )

Ù5µ 1-26mm Fair 合理

ER 筒夾式刀把

(鋼珠螺帽) 高速加工在精加工時,建議使用有減震功能之刀把,且選擇 高速加工相較於傳統加工,有著低切削深度但高轉速、高進給

短刃具圓角之刀具,並減少刀長伸出量,以傾斜角度和最少 之特性。來達到高金屬移除率(減少生產時間、提高生產效率)之

量潤滑(MQL) 加工來獲得最佳效果。 目標。因切削負荷較低,夾持力要求也也相對較小。故選擇高

PFC Milling Chuck 4-32mm

強力銑刀刀把 Ù10µ Middle 中等 速加工用之刀柄時應注重其動平衡性及精度。

For finishing in HSM, we recommend to use the tool holder High Speed Machining has the characteristics of low depth of cut

with vibration damping characteristic and also the cutting tool but high feed rate and high spindle r.p.m. to reach high material

SLE Side Lock Chuck 6-42mm that has a shorter length with corner radius with shorter remove rate compares to conventional machining. The cutting load

側固式刀把 Ù10µ Low 低 overhang to machine with inclination of the cutter in the feed is also lighter. Therefore, the selection focus of tool holder for HSM

direction together with Min. Quantity Lubrication to have the is balancing and accuracy.

best performance.

13