Understanding the BT Tool Holder (Tool Holder) System - Tool Holder and Handle Parts

What is a BT tool holder (tool holder)?

BT tool holder (tool holder) is a tool holding system widely used in CNC machine tools. BT was originally a specification stipulated by the Japan Machinery Association, called (MAS403 BT). A few years ago, it was incorporated into the JS specification called JIS B6339 . The BT tool holder features a specific taper and internal tie rod design that allows the tool holder to be tightly fixed in the spindle and reduce tool deflection during machining. This design not only ensures the rigidity and durability of the tool handle, allowing it to maintain a stable clamping state under high-speed and heavy cutting conditions, but also improves the efficiency of tool changing and greatly improves production efficiency. Its tool handle is simple in design and versatile, so it is regarded as the first choice by many CNC machining centers.

Features of BT knife handle

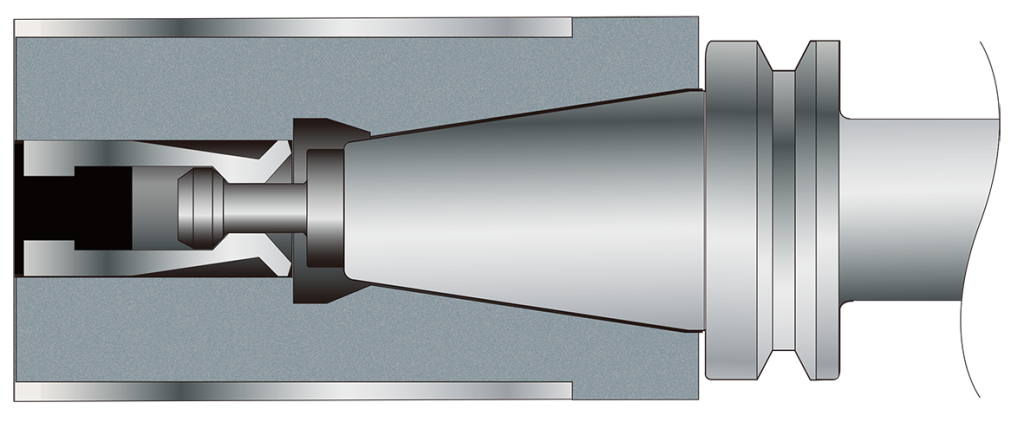

High rigidity design: BT tool holder adopts a large taper design of 7:24. The cone of the tool holder is in tight contact with the inner cone surface of the spindle under the action of the axial tension of the tie rod. The solid cone is directly supported in the taper hole of the spindle. The overhang of the tool can be reduced, which makes the contact area between the tool holder and the machine tool spindle larger, providing higher rigidity and stability.

High-precision positioning: The taper and end contact design of the BT tool holder can ensure high-precision positioning of the tool in the spindle, which helps improve machining accuracy and workpiece surface quality.

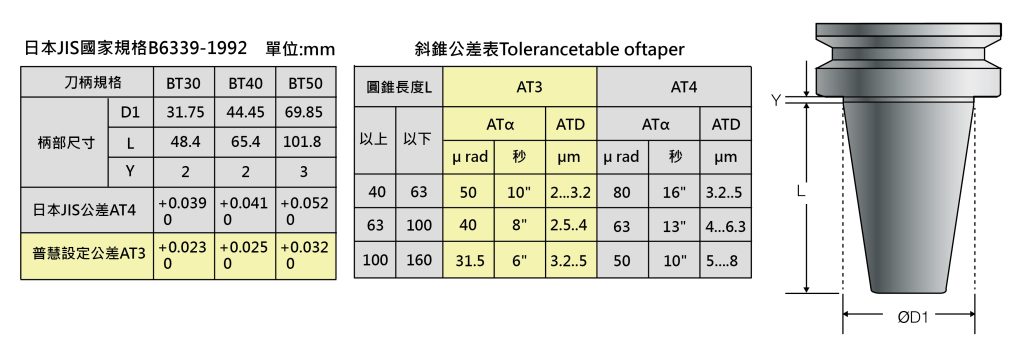

Stable clamping force: The structural design of the BT tool holder can be clamped at the contact area between the tapered shank of the tool holder and the inner taper hole of the spindle. The tightness tolerance of the tool holder shank and the inner hole of the spindle is divided into 9 levels (ISO1947) from AT1 to AT9. The higher the internal tolerance level (the smaller the number), the closer the tool handle and the inner hole of the spindle are. Generally, A4 is the standard grade, but AT3 or the lamination area reaches the production standard of 85%, which can better exert the mechanical benefits in processing, which further improves the clamping stability and reduces the offset and vibration of the tool during the processing.

BT knife handle size specifications

BT knife handles are available in a variety of sizes. Common sizes from small to large are BT30, BT40, and BT50. Therefore, the difference between BT30 and BT40 is the different taper sizes of the knife handles. BT30

Recommendations for using and maintaining BT knife handles

Regular inspection and cleaning: Regularly check the taper and end contact parts of the tool handle to keep them clean and free of dirt to ensure clamping accuracy and stability.

Correct clamping force: Use standardized clamping tools and methods to ensure appropriate clamping force and avoid excessive clamping or loosening, which affects processing accuracy.

Prevent collisions and injuries: During operation and storage, avoid collision and damage to the knife handle to extend its service life.

To learn more, please go to the official website: Precision tool handle selection BT series selection