Balancing

BALANCING

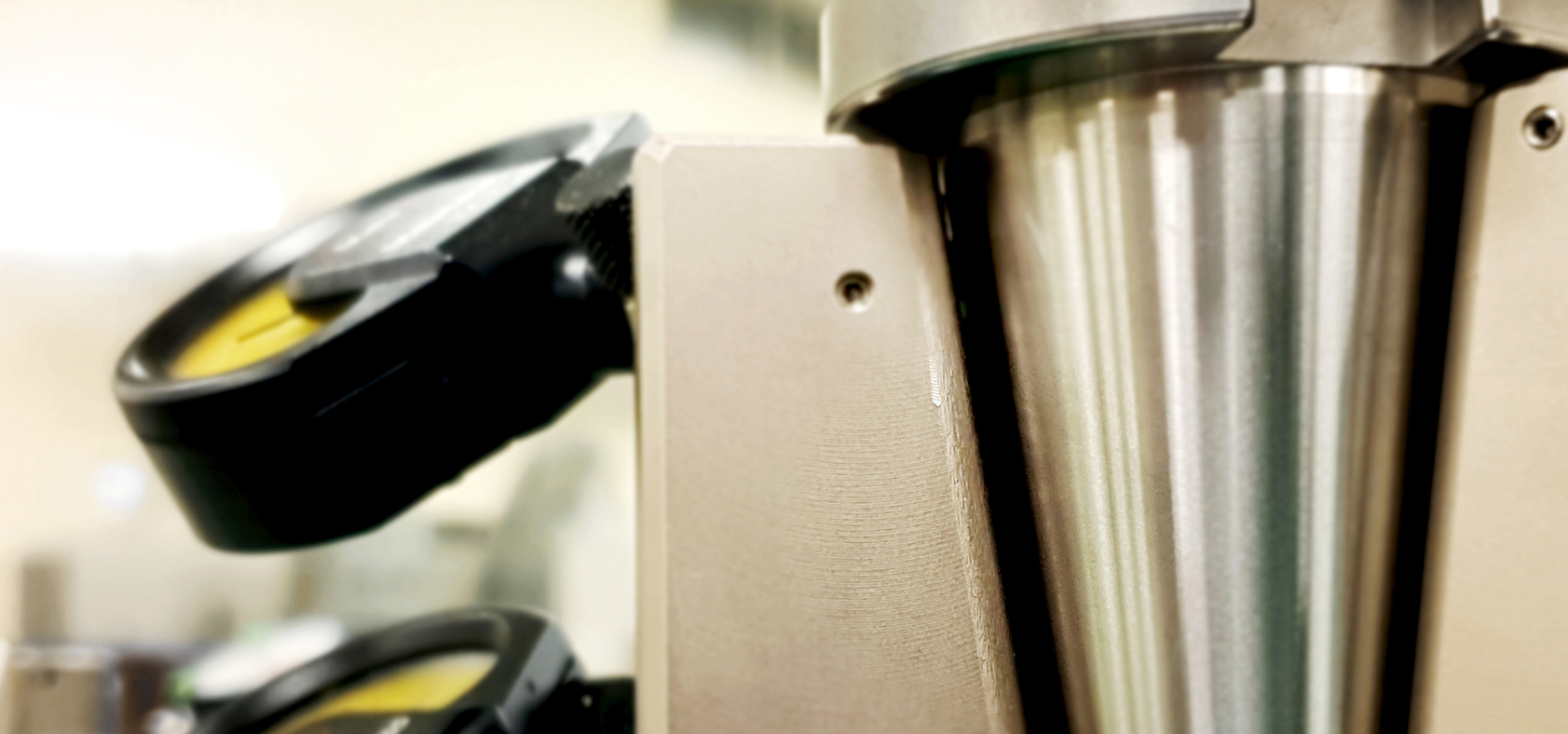

With the growing popularity of high speed cutting machine there are two basic measurements which are accuracy and balance. The imbalance of tool holder is sourcing from mechanical property, for example, it may be caused by set screw in the tool holder of milling cutter or various depth of keyway in CAT tool holder. These causes appear randomly with no fixed rules, therefore, under any circumstances, users have to make up for the imbalance to achieve the purpose of balancing.

In general the tools with up to 8,000rpm of spindle speed are required to make up for imbalance. The balancing grades are from G4,000 to G0.4 total 11 grades according to ANSI S2.19. The smaller number stands for the higher grade. Furthermore, the balancing unit should be under g?mm or oz?mm as a unit for the imbalance amount. The formula is as follows:

Uper = G/ω →Uper = 9549 x G x W / n

Uperis the allowable unbalance, G is the balancing level, W is the weight of the tool holder, n is the speed

Assuming that the weight of the tool holder is W=1Kg, the dynamic balance level G6.3 is required. And at a speed of 15,000RPM, the allowable balance is 9549 x 6.3 x 1 / 15,000=4.011 (g.mm)

The allowable balance is

9549 x 6.3 x 1 / 15,000=4.011 (g.mm)

The Importance of Balancing

We must notice that centrifugal force generated by imbalance is proportional to the square of spindle speed. In other words the tiny amount of imbalance generated by 1,000 rpm will be increased 100 times by 10,000 rpm, and 400 times by 20,000 rpm. If the tool can not keep rotating in the spindle central line under the trend of more and more higher speed of spindle it is definitely the reason for extra imbalance caused. Thus the excellent concentricity becomes more important. With poor handling imbalance the centrifugal force caused by high spindle speed will generate vibration or tremor which must be prevented. The influences of vibration or tremor as follows:

Machine Spindle

When passing vibrations or tremors to the bearing and over the bearing load, the temperature will rise and thereby reduce the bearing life.

Tool Life

When passing vibrations or tremors to the bearing and over the bearing load, the temperature will rise and thereby reduce the bearing life.

Workpiece

The vibration or tremor will change the cutting load, thereby, it will substantially reduce the tool life.

Industrial Safety

There are industrial safety hazards with many real cases such as the tool holder flying out to hurt the operators caused by high spindle speed and imbalancing.

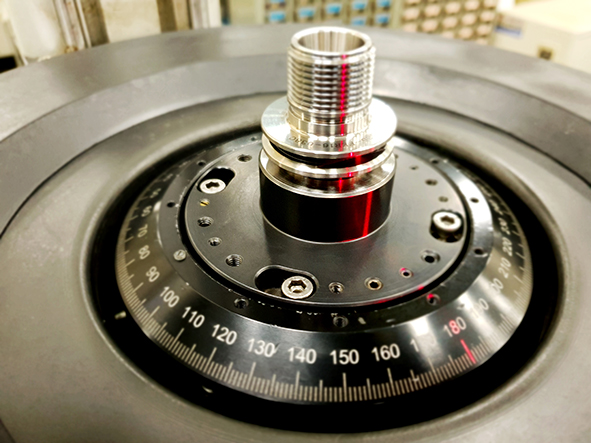

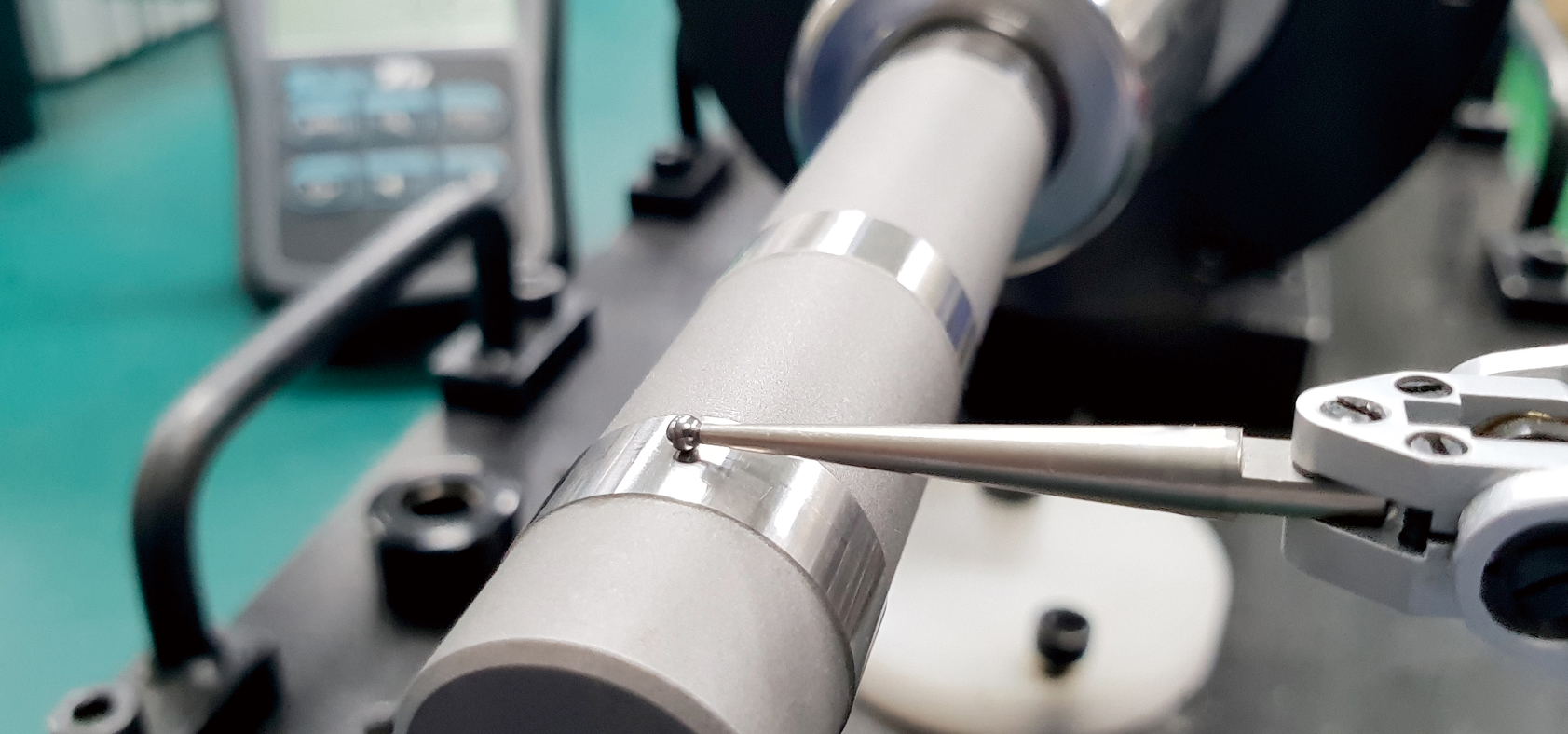

The Balancing Grade of PARFAITE tool holder

PARFAITE is able to reach G0.4 which other manufacturers generally can not achieve because we assemble with high speed spindles. PARFAITE knows customer's needs of balancing varying with machine properties well. We are able to not only attaching basic balancing for high speed cutting tool holders but also providing the first class equipments and services for adjusting balancing of tool holders according to the type of high speed spindle. Finally, for the best result, users should assemble the draw bar tool holder, collet, nut and tool assembly. Then users are able to adjust the balancing to obtain the best result. Only balancing the tool itself can not guarantee the final balancing grade after combination because the draw bar, collet, nut and tool itself have certain weight and factors of imbalancing. Furthermore, any replacement or adjustment of tool, any parts of tool holders or re-grinding tools... may affect the original balancing grade.