Run-Out and Repeat Accuracy

RUN-OUT & REPEAT ACCURACY

The run-out accuracy refers to the deviation after the tool is fixed on tool holder.

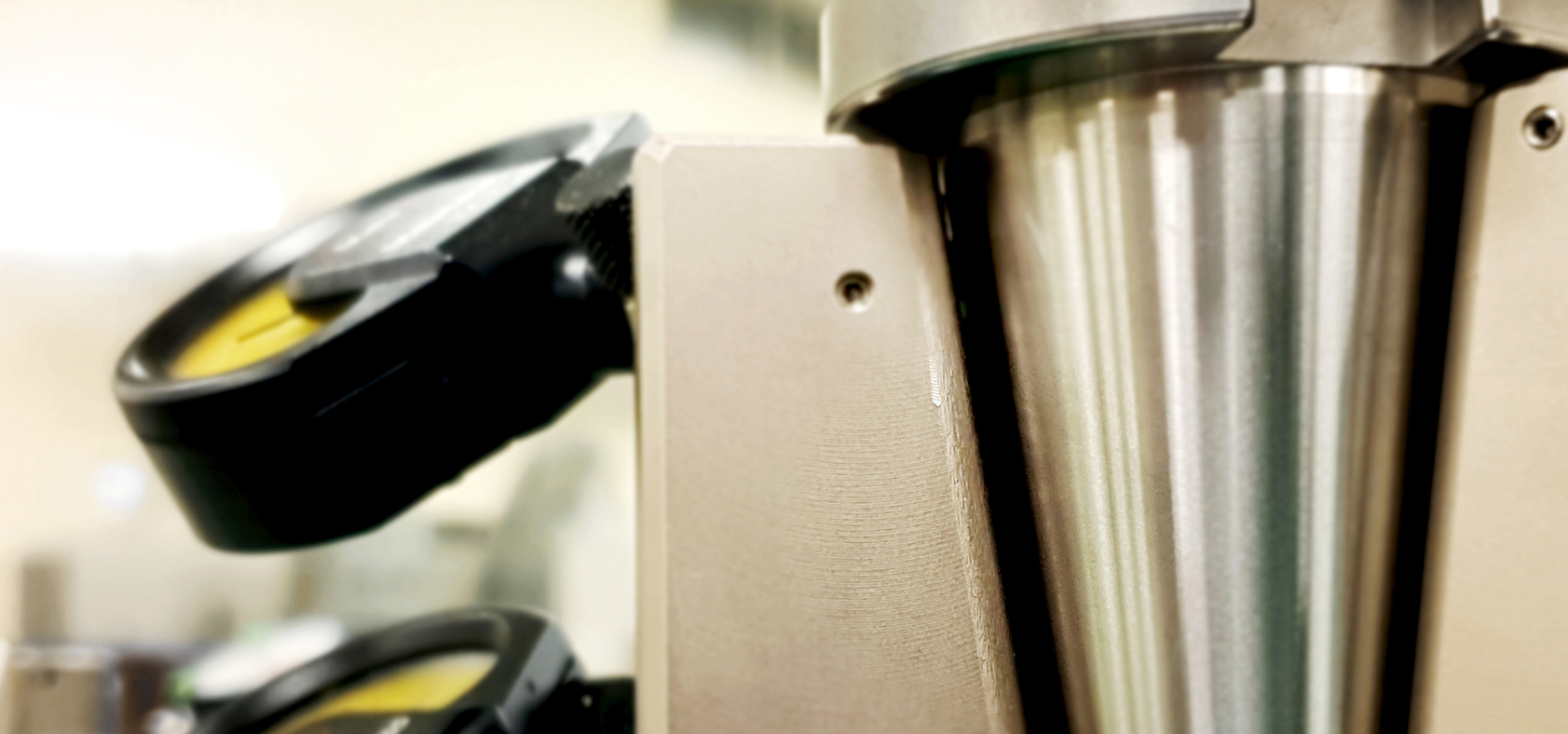

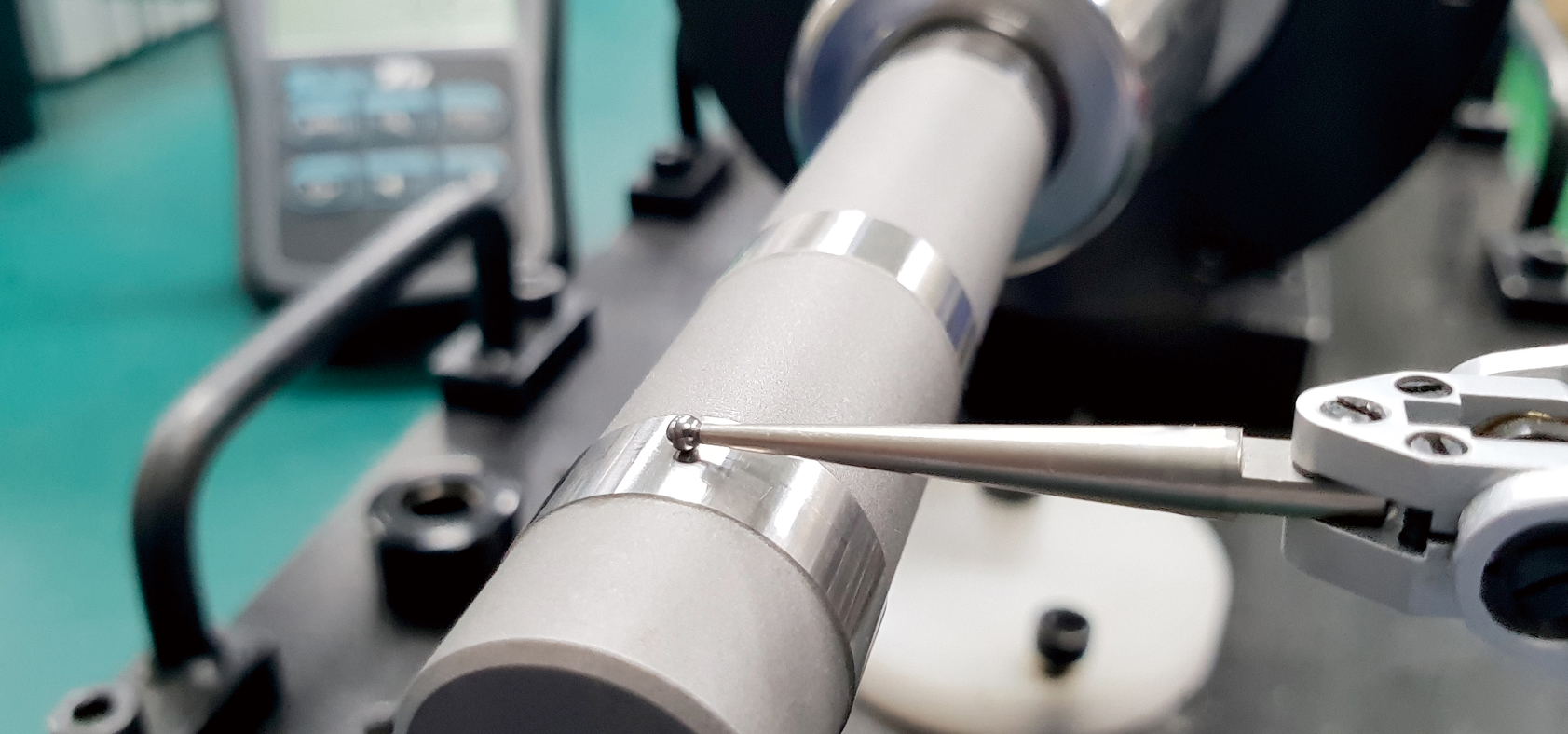

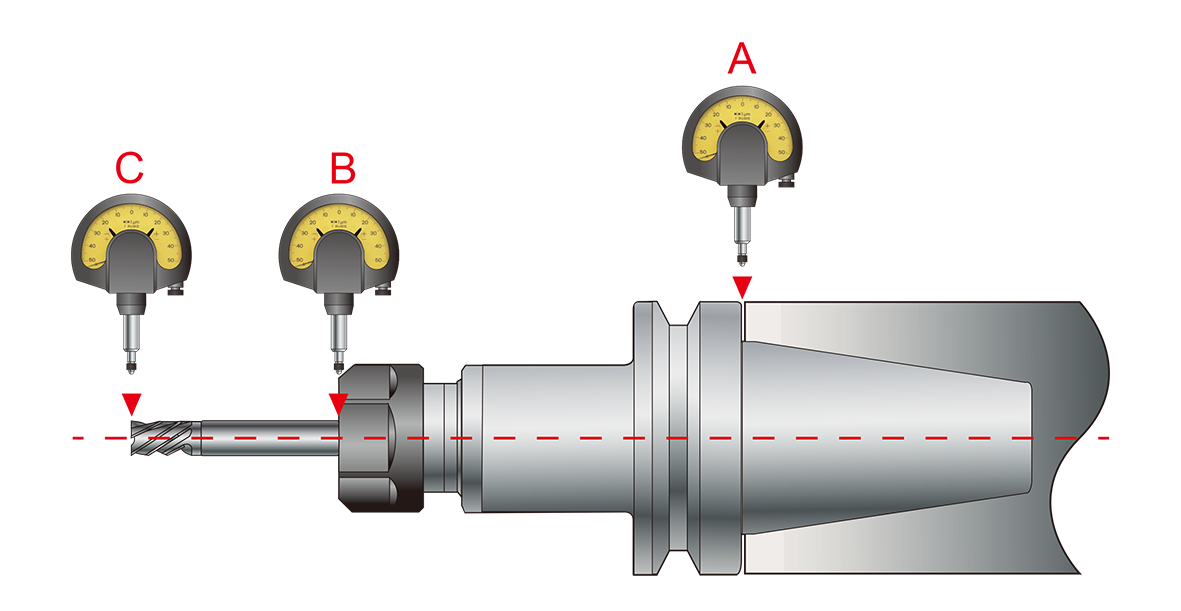

The run-out accuracy refers to the deviation after the tool is fixed on tool holder. The measuring method is to attach a testing taper to the several times length of handle's bore and rotate 360 degrees then to get the deflection. As showed below the testing taper is fixed on the measuring instrument. A is the basic point,then to rotate 360 degrees to measure the deflection of point B and C. The distance of the tool holders nose(point B) and point C is showed in the times of the tool holders bore size, ( assuming the tool holder bore size d is 6mm, 4 times/ 4d is 24mm). The repeat accuracy refers to measure the changes of accuracy when handle repeats disassembled or clamped. The longer length of Point C is, the more difficult is to maintain the run-out accuracy and repeat accuracy.

Generally the length is mainly from 2.5 times to 4 times for most manufacturers. The users should notice whether the accuracy is clamping accuracy or repeat accuracy showed by manufactures and the measurement is only made at point B or the length is 2.5d, 3d or 4d when making a purchase.

The Importance of clamping accuracy and Repeat Accuracy

Meet the standard of the surface roughness and machining accuracy

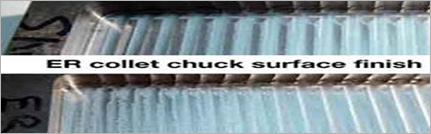

The higher clamping accuracy stands for the less deviation on the end, therefore, the user is able to meet the accuracy and roughness requirements easily. As showed below (ER vs. HY) the tool holder's accuracy is higher, the roughness is much better compared to those with lower accuracy. Furthermore, the poor accuracy will cause bigger holes, poor surface accuracy and poor roundness etc.

Save the machining Time

As mentioned above it is able to reduce reoperation time for accuracy /surface roughness failure caused by poor accuracy and inspection frequency. In addition it can dramatically reduce time of adjusting tool by adopting high repeat accuracy tool holder. We assume that the cost of a machine and a labor is 10 NTD and at least 500NTD is wasted on repeat operation and adjust tools under the condition of sale prices and the profit decreased sharply as well as over capacity production. The tool holder with high accuracy and repeat accuracy will bring more valuable which is far better than the price itself.

In an environment where selling prices and profits are plummeting or the production capacity is overloaded, assuming that the cost of machine processing personnel per minute is 10 yuan, the cost of wasted in heavy industry or calibration knife at least 500 yuan a day. The benefits of a tool holder with high clamping accuracy and repeatability are far greater than the price of the tool holder itself.

Protecting and Extending Tool Life

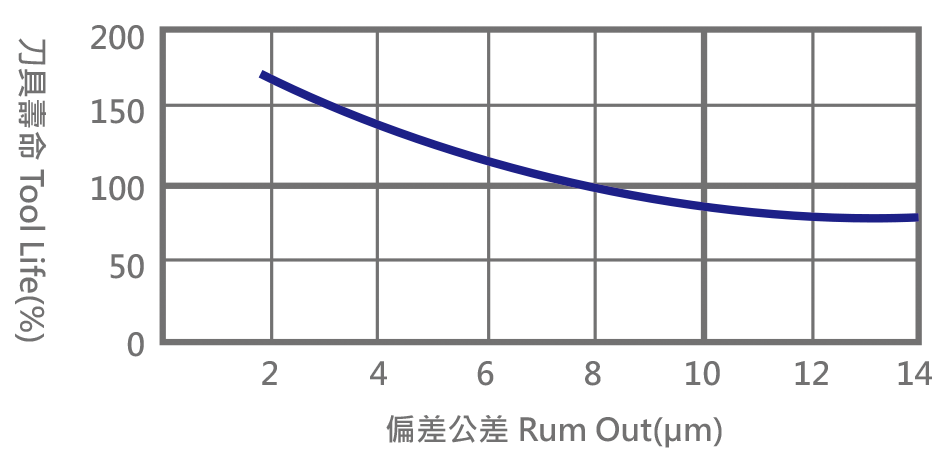

Each edge of the blade is less worn if the accuracy is high which means the deflection of the end of tool is small and gets average force. It will not be shorten the tool life because the blade doesn't get unequal force by the deviation to be over worn.The followed figure compares the accuracy and the tool life, the accuracy is 0.01mm as a benchmark, if accuracy increases to 0.003mm the tool life will also increase over 50%.

PARFAITE sincerely give you an advice that users need not only purchase a tool holder with enough holding force but also with a tool of tolerance over h6 to ensure applying and maintaining the proper holding force.