Taper Accuracy

TAPER ACCURACY

The taper accuracy refers to the tolerance of fit on taper and spindle bore. There are 12 grades of this tolerance from AT1 to AT12. The higher grade of tolerance stands for the more fit on taper and spindle bore. For example the fit of spindle bore size is 85%, and then AT3 is better than AT4. According to ISO1947 standards the AT3 is the most basic requirement to tapers. The part of HSK taper's tolerances are ranged by DIN 69893 from German standards. This tolerance range is fixed and therefore, there are no grades differences. The tolerances must be measured by precise measurement on regular basis. Other measure methods such as visual method by smearing red power paste can not be precise.

The importance of precision grade of Taper:

Protect the accuracy of spindle and extend the tool life

The taper accuracy refers to the tolerance of fit on taper and spindle bore. There are 12 grades of this tolerance from AT1 to AT12. The higher grade of tolerance stands for the more fit on taper and spindle bore. For example the fit of spindle bore size is 85%, and then AT3 is better than AT4. According to ISO1947 standards the AT3 is the most basic requirement to tapers. The part of HSK taper's tolerances are ranged by DIN 69893 from German standards. This tolerance range is fixed and therefore, there are no grades differences. The tolerances must be measured by precise measurement on regular basis. Other measure methods such as visual method by smearing red power paste can not be precise.

Protecting and Extending Tool Life

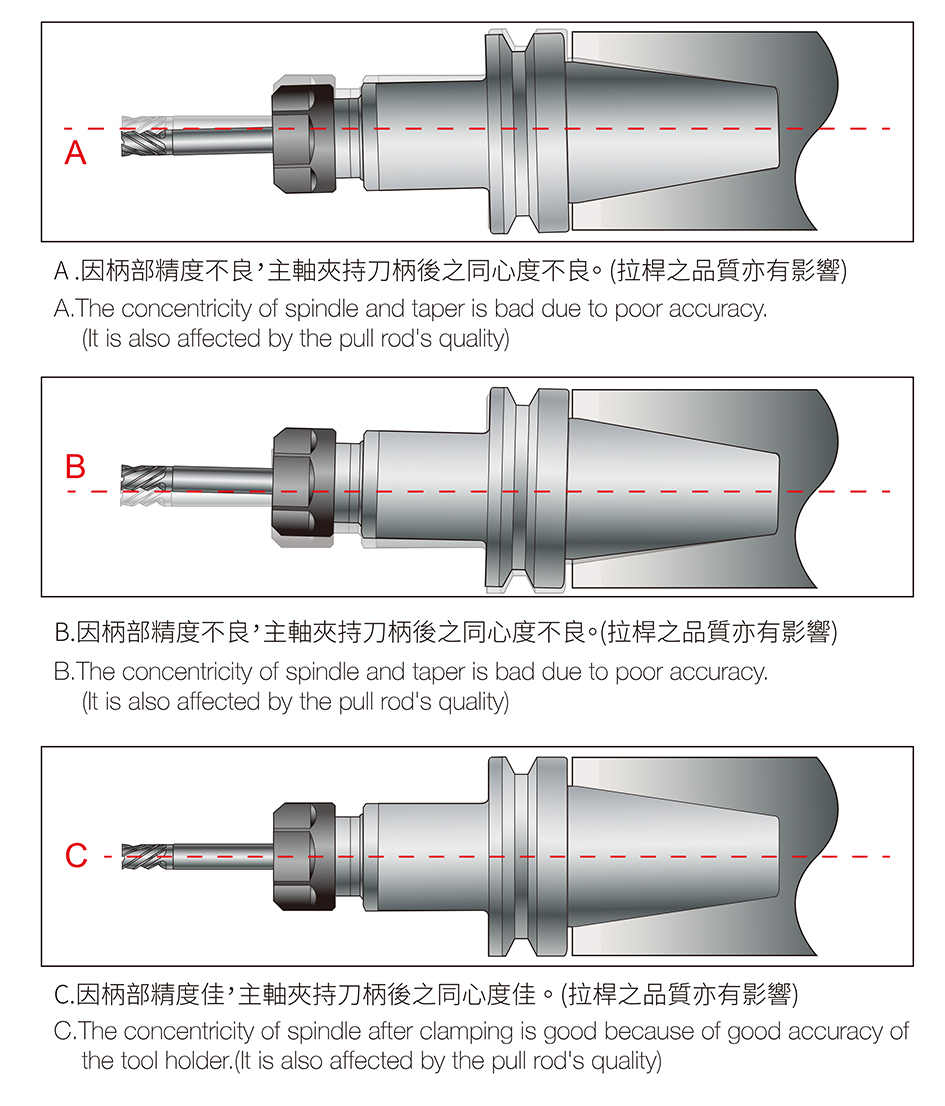

The higher accuracy is the tool life is longer in theories. In fact the front of taper's deflection is caused by the tolerance which is too big on taper and spindle bore size or the loss of accuracy for big tolerance in long term of operation. (Shown as below). Therefore, the lower grade of repeat accuracy is, the more deflection is and it will be worse the accuracy. Furthermore, it will cost significantly when the tool is rapidly weared and increases reject ratio.

Ensure the accuracy and quality

It is a direct proportion of accuracy and deviation, therefore, it is able to ensure the accuracy and the quality.

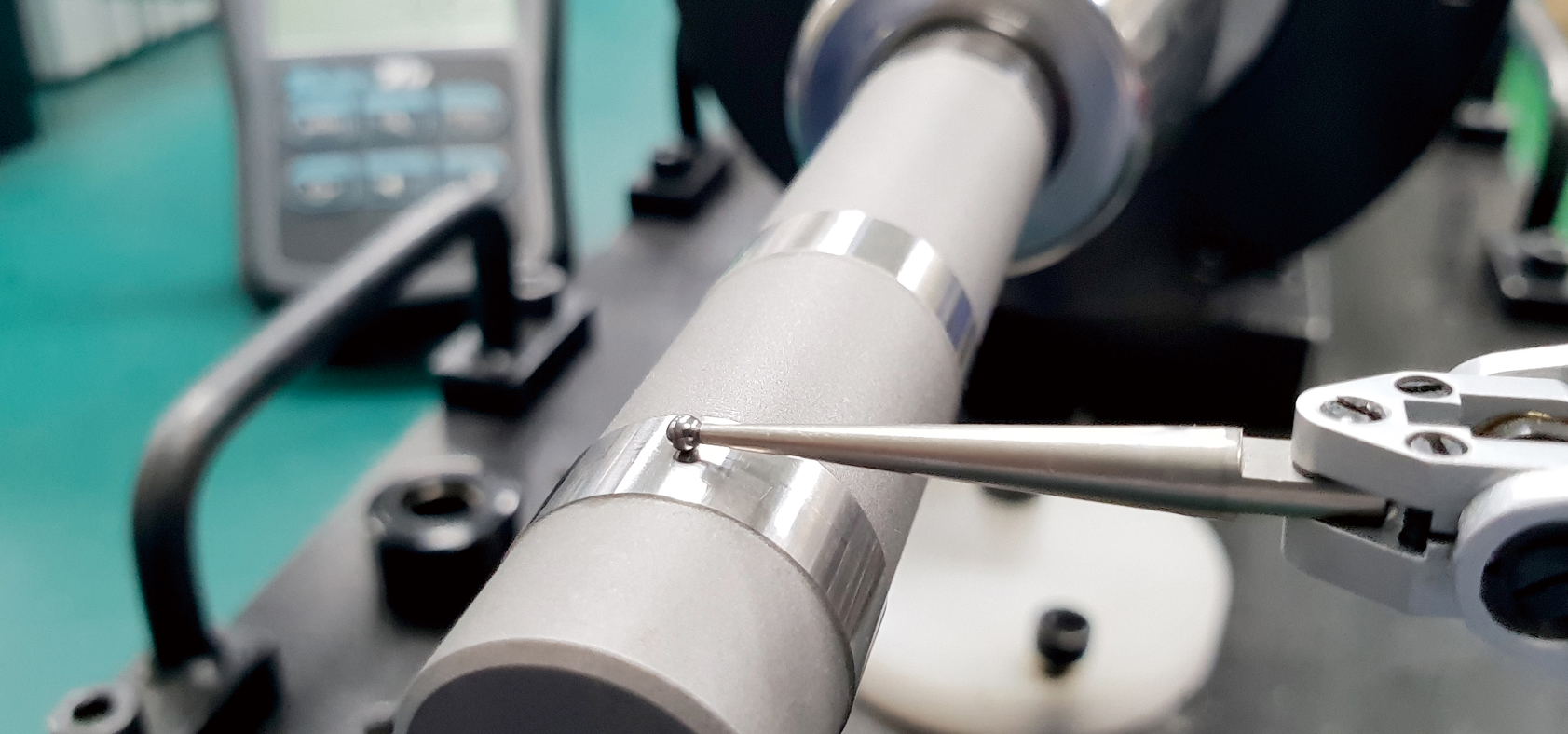

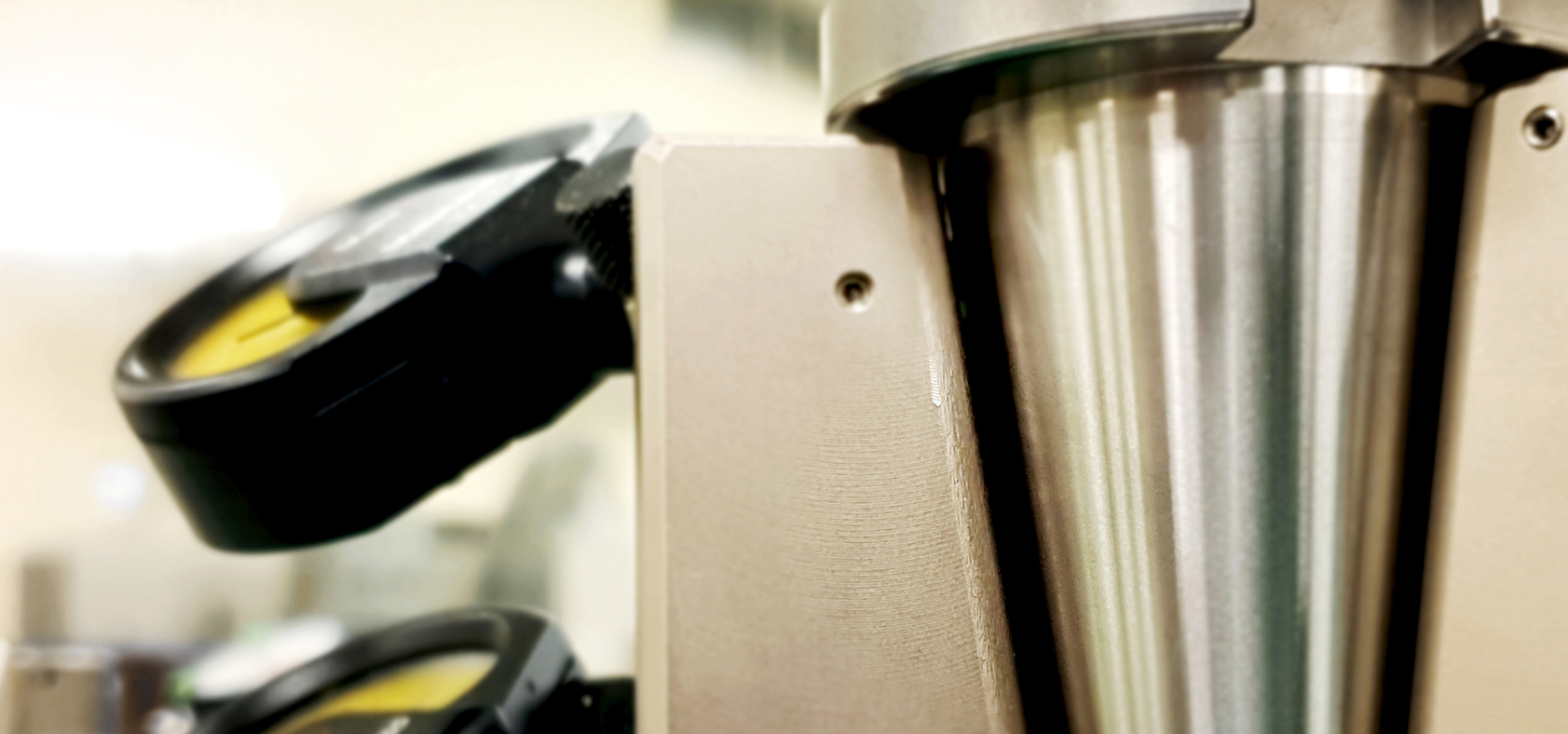

The Accuracy Grade of Tool's Taper Made in PARFAITE

All tapers' fitting areas made in PARFAITE are over 85% or within AT3. The taper's tolerance is guaranteed within DIN 69893's tolerance range in HSK series. The measuring instruments such as air gauge for taper's accuracy are made from German or Switzerland and checked and adjusted on regular basis.