Tool life management optimization: the contribution of RFID tool technology

The Importance of RFID Tool Management

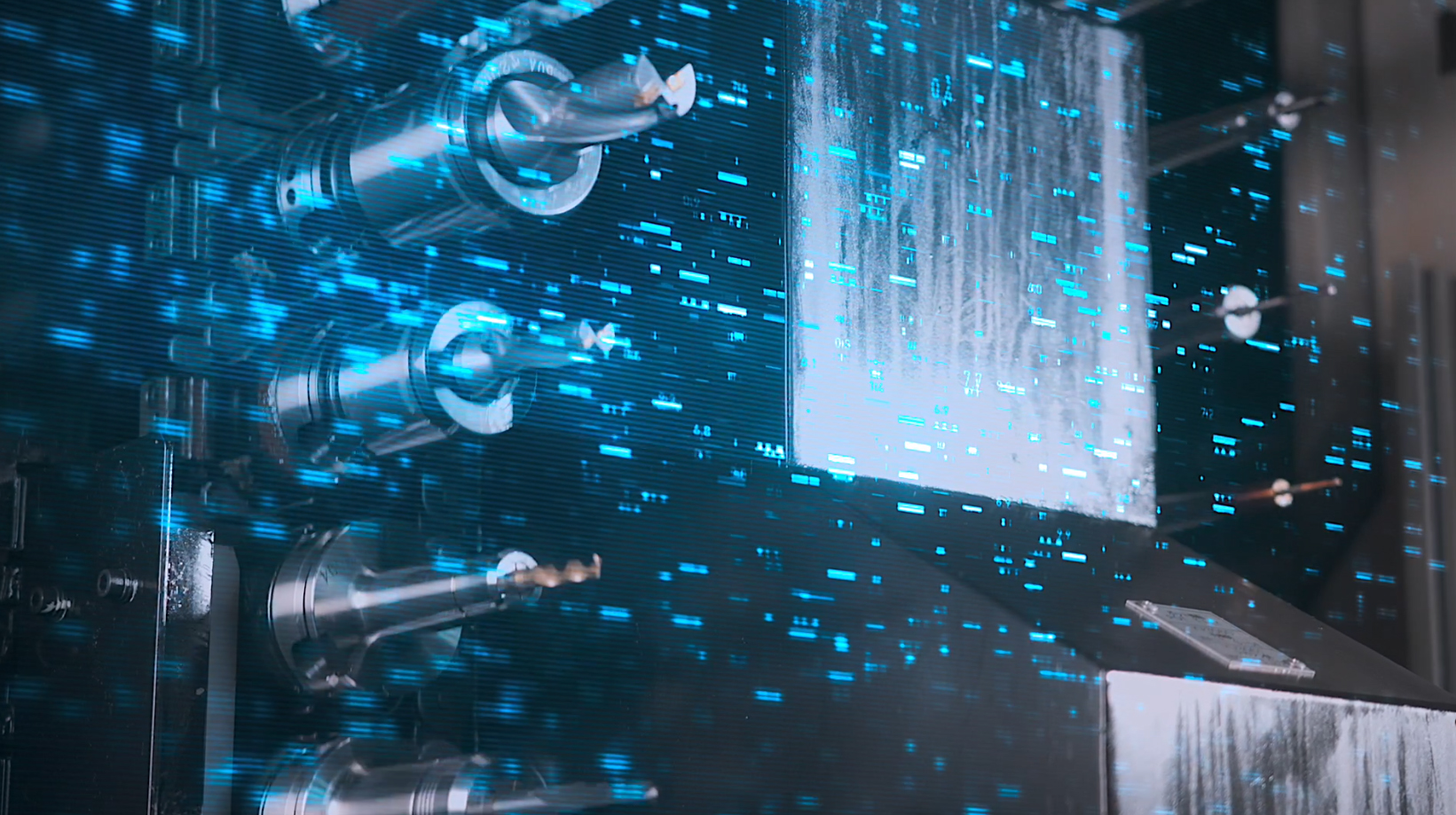

In modern manufacturing, tool management is crucial for improving production efficiency and product quality. With technological advancements, RFID (Radio Frequency Identification) has become a revolutionary tool in tool management. By implementing an RFID tool management system, companies can significantly extend tool lifespan, reduce production downtime, and enhance overall production efficiency. In this article, we will explore the close relationship between RFID tool management and tool lifespan, and how it helps companies stay ahead in a competitive market.

Application of RFID Technology in Tool Management

The application of RFID technology in tool management is extensive and highly effective. RFID tags can be attached to each tool, containing important information such as serial numbers, specifications, usage records, maintenance records, and lifespan predictions. These data are transmitted in real-time to a central management system via reading devices, allowing managers to always keep track of each tool's status.

Operating methods are also crucial factors. Experienced operators can adjust cutting parameters flexibly based on processing conditions, reducing tool wear. Conversely, improper operation can damage tools. Additionally, regular maintenance is vital for tool lifespan. Lack of maintenance leads to gradual wear, eventually rendering tools unusable.

Factors Affecting Tool Lifespan

The lifespan of tools is influenced by various factors, including material quality, processing conditions, operating methods, and maintenance frequency. Material quality directly impacts tool lifespan, with high-quality materials able to withstand greater wear and impact. Inappropriate processing conditions, such as excessive cutting speeds and cutting amounts, accelerate tool wear and shorten their lifespan.

Finally, the automation and intelligence of RFID tool management systems significantly reduce the impact of human factors on tool lifespan. Traditional tool management methods are prone to data errors and management oversights due to human factors. Automated data collection and management through RFID technology ensure data accuracy and integrity, avoiding human interference and effectively extending tool lifespan.

How RFID Tool Management Extends Tool Lifespan

Implementing an RFID tool management system can effectively extend tool lifespan. Firstly, RFID technology accurately records tool usage and wear conditions. Through data analysis, managers can promptly understand maintenance needs and schedule appropriate maintenance plans, preventing maintenance only after excessive wear. This approach maintains tools in good condition and extends their lifespan.

Secondly, RFID technology optimizes tool usage strategies. By analyzing tool usage data, managers can identify the best cutting parameters and processing conditions, avoiding tool use under unsuitable conditions and reducing wear. For example, choosing the right cutting speed and amount based on different materials and processing requirements ensures tools operate in optimal conditions, thus extending their lifespan.

Furthermore, RFID technology enhances transparency and traceability in tool management. Managers can view tool usage history and maintenance records at any time, understanding each tool's specific situation. This transparency and traceability help identify and resolve management issues, improving efficiency. Additionally, this data can be used for operator training, helping them master proper operating methods and reducing tool wear and damage. Finally, the automation and intelligence of RFID tool management systems significantly reduce the impact of human factors on tool lifespan. Traditional tool management methods are prone to data errors and management oversights due to human factors. Automated data collection and management through RFID technology ensure data accuracy and integrity, avoiding human interference and effectively extending tool lifespan.

Long-Term Benefits of Investing in RFID Tool Management

Investing in an RFID tool management system offers significant long-term benefits for companies. Firstly, effective tool management can considerably extend tool lifespan, reduce replacement frequency, and lower production costs. Secondly, RFID technology can improve production efficiency, reduce downtime, and ensure stable production processes. Moreover, precise data analysis and management help companies identify and resolve production issues, enhancing overall production efficiency.

In a competitive market, advanced tool management technology becomes a crucial means for companies to maintain a competitive edge. The RFID tool management system not only improves management efficiency but also provides scientific data support, helping companies stay undefeated in the market. Therefore, companies should actively adopt RFID tool management technology to ensure efficient production processes and achieve higher production benefits and competitiveness.