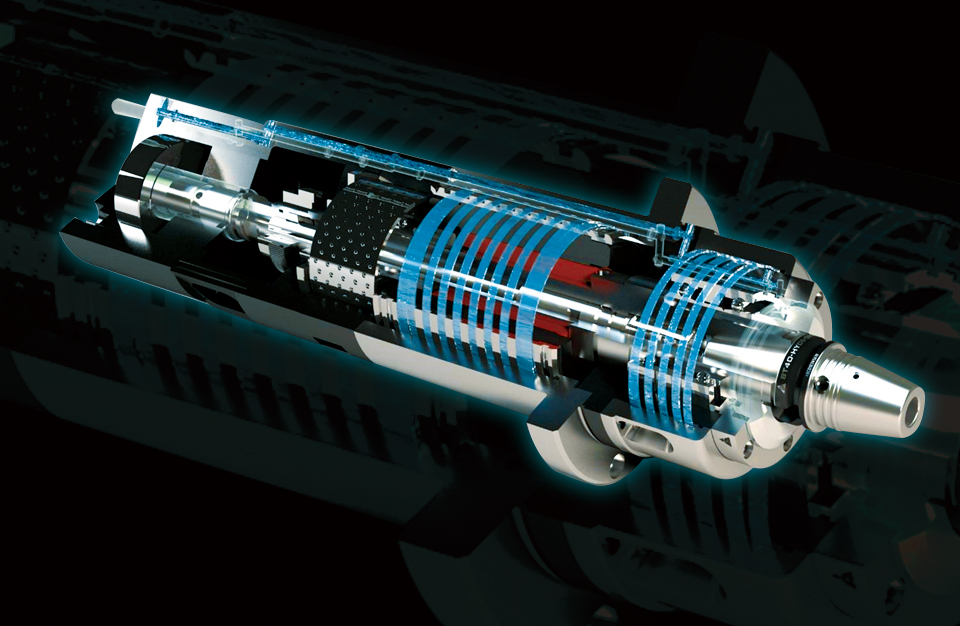

The built-in high-speed spindle commonly used in modern machine tools is a high-tech integrated spindle design, in which the motor stator and rotor are arranged inside the spindle and integrate oil, gas, water and electricity in a limited space. , unstable factors are also integrated into one, so the technical level is relatively high, but this design can improve efficiency and accuracy, thereby reducing spindle vibration and noise. The high-speed spindle has high cutting rate and high feed rate during processing, which reduces processing time and improves production efficiency. At the same time, the built-in spindle has better rigidity and smaller vibration conditions, which promotes the geometric accuracy and surface processing of the completed workpiece. Excellent performance in thickness.

In addition, the built-in spindle also has the following features:

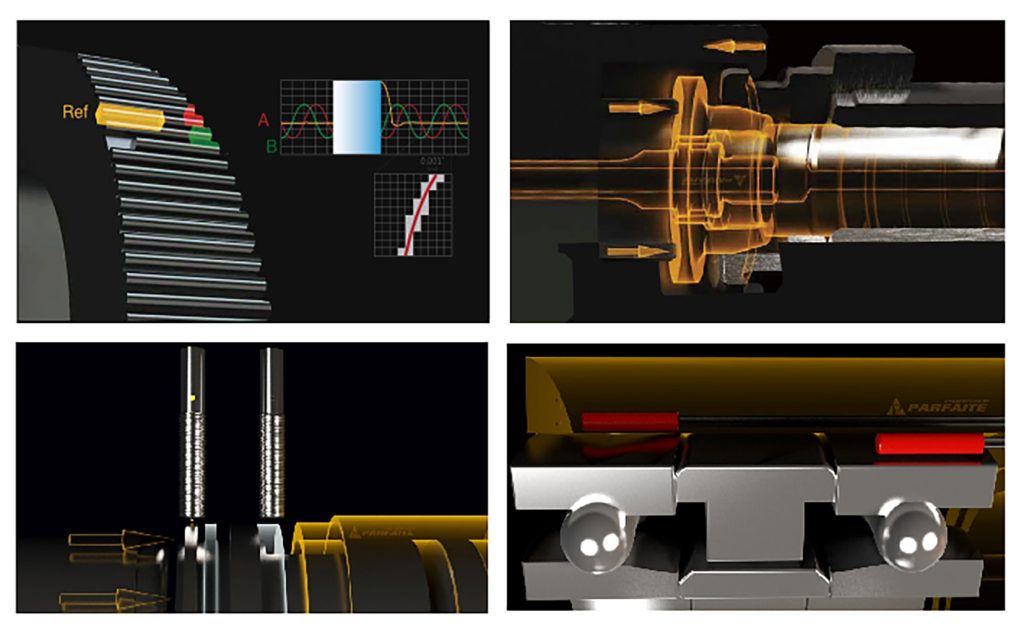

1. High rigidity bearing configuration:Built-in spindles are usually equipped with highly rigid bearings, which can provide better cutting accuracy and reduce the surface roughness of the workpiece.

2. Low noise and low vibration:Since the motor rotor is arranged inside the spindle, the built-in spindle can achieve low noise and low vibration.

3. Low environmental pollution:The design of the built-in spindle can reduce the scattering of lubricating oil in the environment, so the pollution to the environment is low.

4. Rich changes, integrated design:Built-in spindles usually adopt an integrated design, which can shorten the production cycle and reduce maintenance costs.

5.High speed operation:The built-in spindle can usually reach higher speeds, such as 15,000 rpm, 18,000 rpm, or even 30,000 rpm. Different levels of rotation speed can be selected depending on the needs of the processing machine.

5 basic guides to understanding built-in spindles

1. Speed range: During the operation of machine tools, the selection of speed range is crucial to ensuring processing efficiency and quality. Different materials and processing requirements may require different speeds, so choosing a built-in spindle with a wide speed range can provide greater operational flexibility to meet various processing needs. For example, when processing harder materials, a lower speed may be required, while when processing soft materials, a higher speed may be required. Therefore, a built-in spindle with a wide speed range can meet various processing needs and improve production efficiency.

2. Power and torque: The power and torque of the spindle directly affect the processing efficiency and quality. A built-in spindle with high power and torque can complete a large number of machining tasks in a short time and can handle harder materials. For example, when performing deep hole drilling or large diameter drilling, a spindle with high torque is needed to provide sufficient cutting force; while when performing high-speed milling or drilling, a spindle with high power is required to ensure cutting efficiency.

3. Rigidity: The rigidity of the spindle refers to its stability when subjected to cutting forces. A rigid spindle can ensure precision during cutting and reduce the surface roughness of the workpiece. When selecting a built-in spindle, you need to consider factors such as its material, structural design, and manufacturing process. These factors will affect the rigidity of the spindle. For example, a built-in spindle made of high-strength steel with a reasonable structural design, precision machining and heat treatment will usually have better rigidity than a spindle made of ordinary steel with a simple structural design and without precision machining and heat treatment.

4. Thermal stability: The thermal stability of the spindle refers to its temperature stability after long-term operation. A spindle with good thermal stability can ensure that the cutting accuracy will not be affected or the machine will overheat due to excessive temperature after long-term operation. When selecting a built-in spindle, factors such as its heat dissipation design and the thermal conductivity of the material need to be considered.

5. Lifespan and maintenance cost: The lifespan and maintenance cost of the spindle are important factors to consider when choosing a spindle. A long-life, low-maintenance spindle can save users a lot of maintenance and replacement costs. When choosing a built-in spindle, factors such as durability, maintainability, and the price of replacement parts need to be considered.