Do you know the HSK-T tool holder system of the turn-mill combined processing machine? tool handle part

In the application of turning and milling compound machine tools, toolholder systems with HSK-T interface are often seen. So what is the structural form of HSK-T?

A brief discussion on HSK-T tool handle system

HSK-T type or the standard called ICTM type. ICTM is the abbreviation of Japan Composite Machine Tool Interface Committee. The committee was jointly formed by Japan's major carbide tool manufacturers and tool system manufacturers in early 2001. Its full name at that time was " The Composite Machine Tool Interface Research Committee" mainly includes the HSK-A type (ISO standard: ISO12164-1:2001) used on the spindle of machining centers and the new HSK system suitable for turning processing on interchangeable multi-processing machines. HSK-T implemented the JIS standard (JISB6064-3) in 2013. The main technology of this standard is to set a higher tolerance fit standard for a pair of driving key connections in order to increase or improve the driving accuracy. ICTM type tool holders are often used as an option in the HSK-A tool holder system. It is called HSK-T type by everyone.

Description of the main features of HSK-T type tool handle:

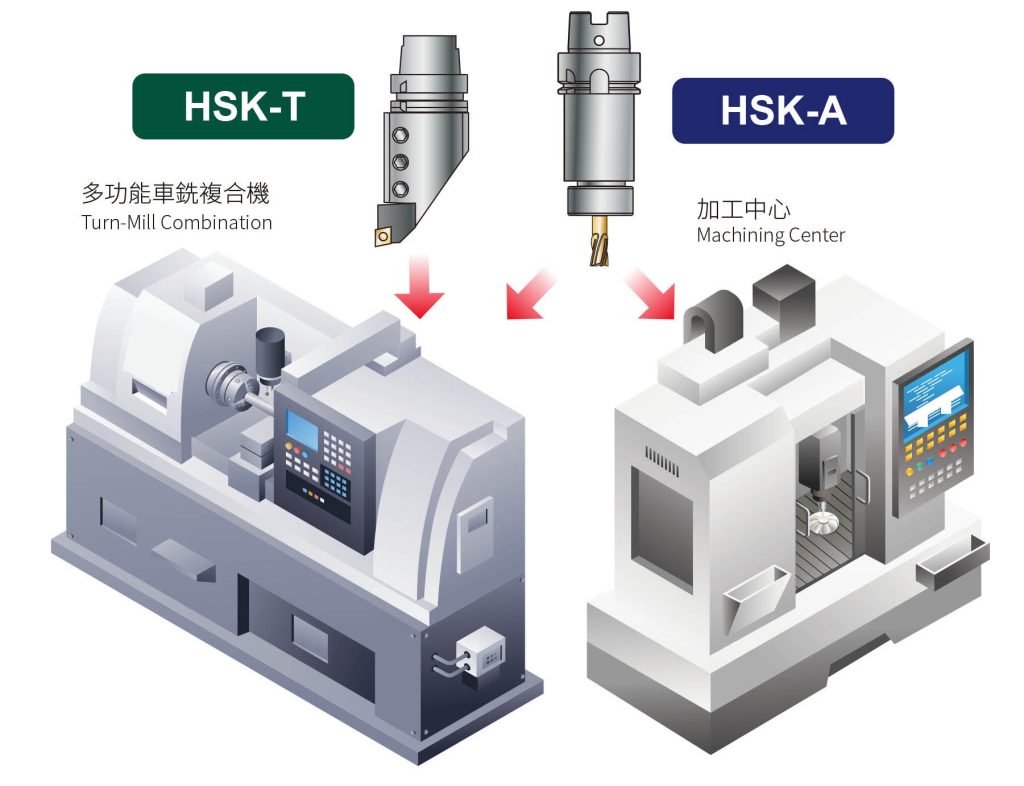

1. Compatibility of tool holders between turning and milling combined processing machines and machining centers

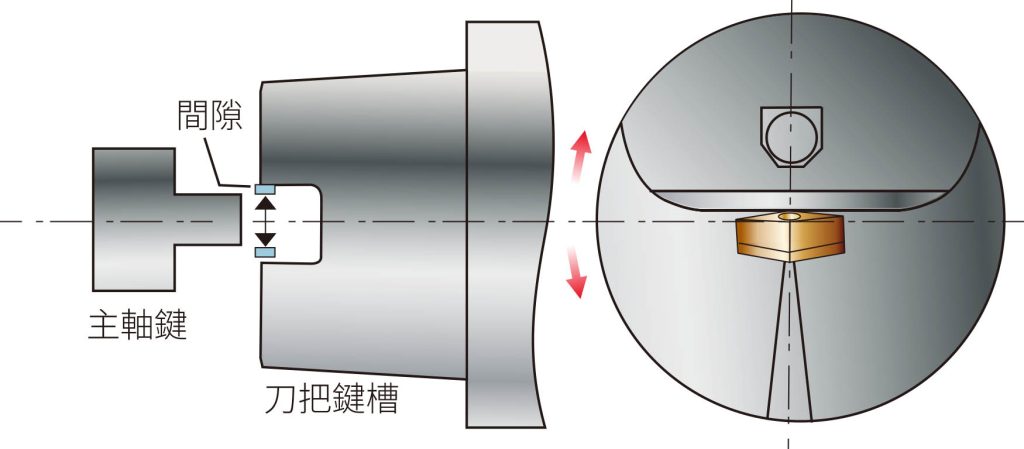

The turning and milling combined processing machine combines turning and milling processes into one machine, saving tedious man-hours of correction and reset. However, because the HSK-T model has stricter tolerances on the spindle key and toolbar keyway, it can achieve high-precision tool tip positioning in turning processing, and it is a system more suitable for this machine model. In addition, if the HSK-A type tool holder system originally used in milling machining centers can still be used, the compatibility of the two tool holder systems can be achieved in the turn-milling compound processing machine.

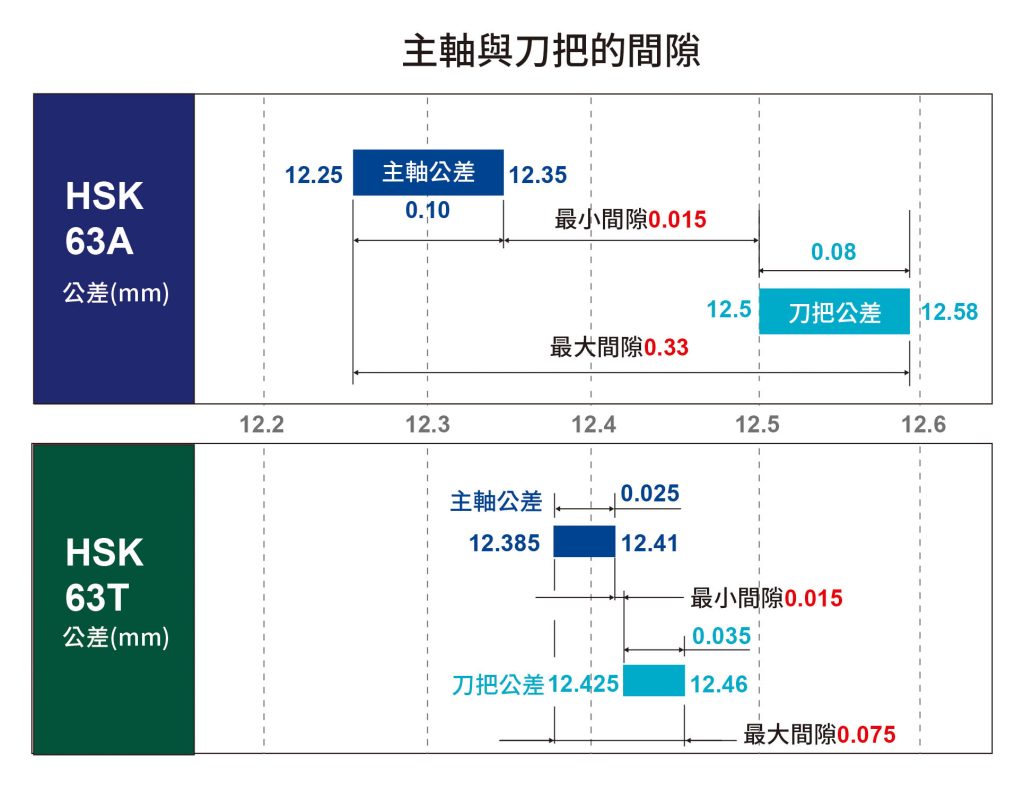

2. Fitting tolerances more suitable for turning processing

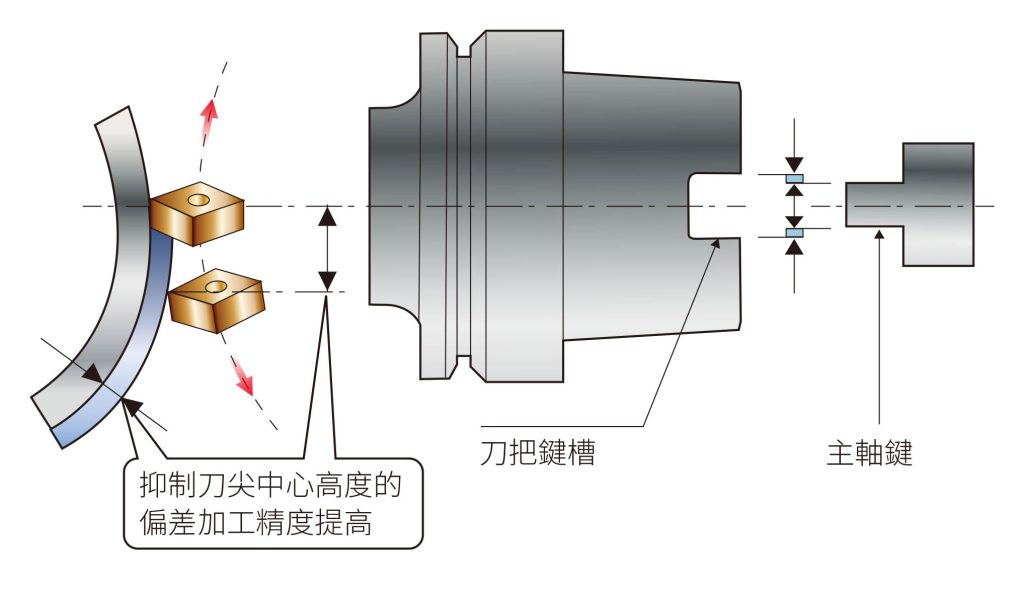

The HSK-T type tool holder system reduces the distance between the spindle and the tool holder, improves accuracy and maintains the height of the cutting edge, suppresses deviations caused by the cutting diameter, and increases better cutting accuracy.

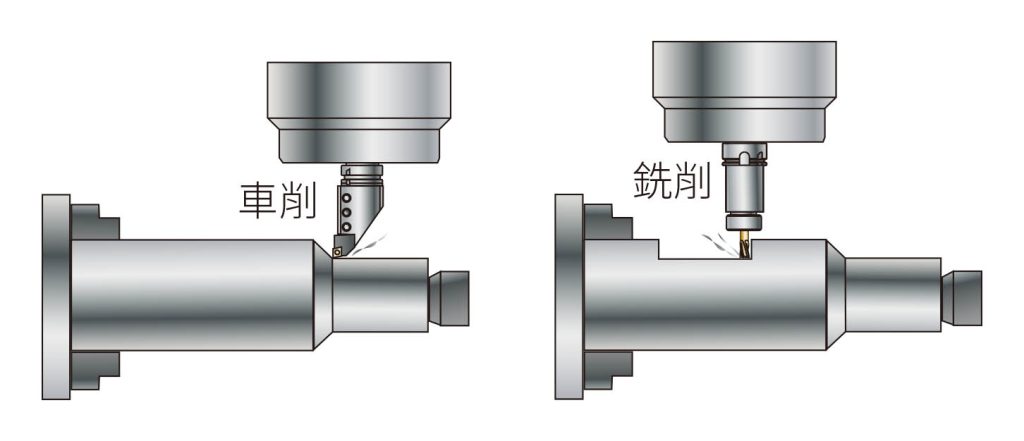

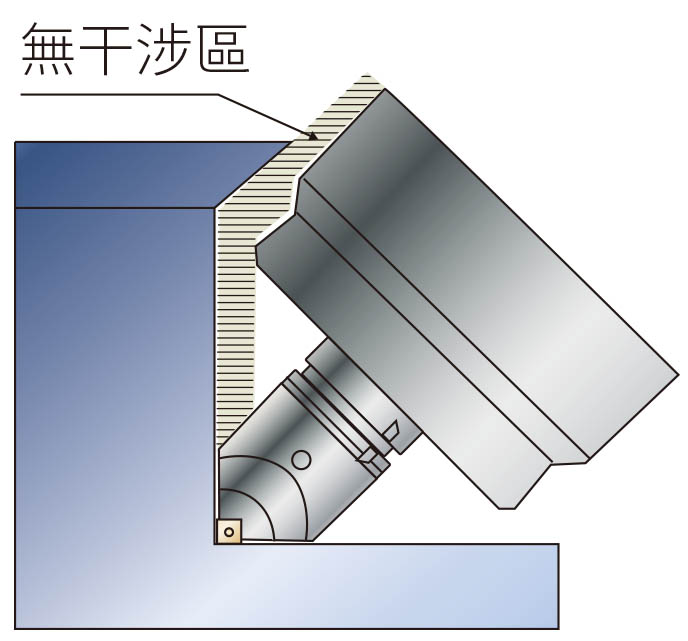

3.Straight shank type tool most suitable for turning and milling combined processing machines

Excellent accessibility to avoid interference with workpieces, the B-axis of the machine tool (tool spindle) is tilted at a specified angle to prevent the spindle, tool holder, workpiece and chuck from interfering.

The tool tip is arranged on the center of the spindle, which can improve the accuracy of the center height., the center height of the tool tip will not be affected by the gap between the key matching part between the spindle and the tool holder, enabling more stable and high-precision machining.

What is the difference between HSK-T type knife handle and HSK-A type knife handle?

Specifications are different:

The HSK-T system specification is JISB6064-3, and the HSK-A system specification ISO12164-1:2001, JIS-B60064-1 and DIN69893 have relevant specifications.

Bonding tolerances vary:

In order to achieve high-precision tool tip positioning in turning processing, the matching tolerances of the spindle key and toolholder keyway of the HSK-T type are smaller and stricter than those of the HSK-A type.

Differences in processing machine applications:

The HSK-T type is mainly used in the turning technology of turning-milling compound processing machines. The HSK-A type system can also be used in milling processing. However, general machining centers do not have turning functions and only use the HSK-A type milling system.