January 27, 2026

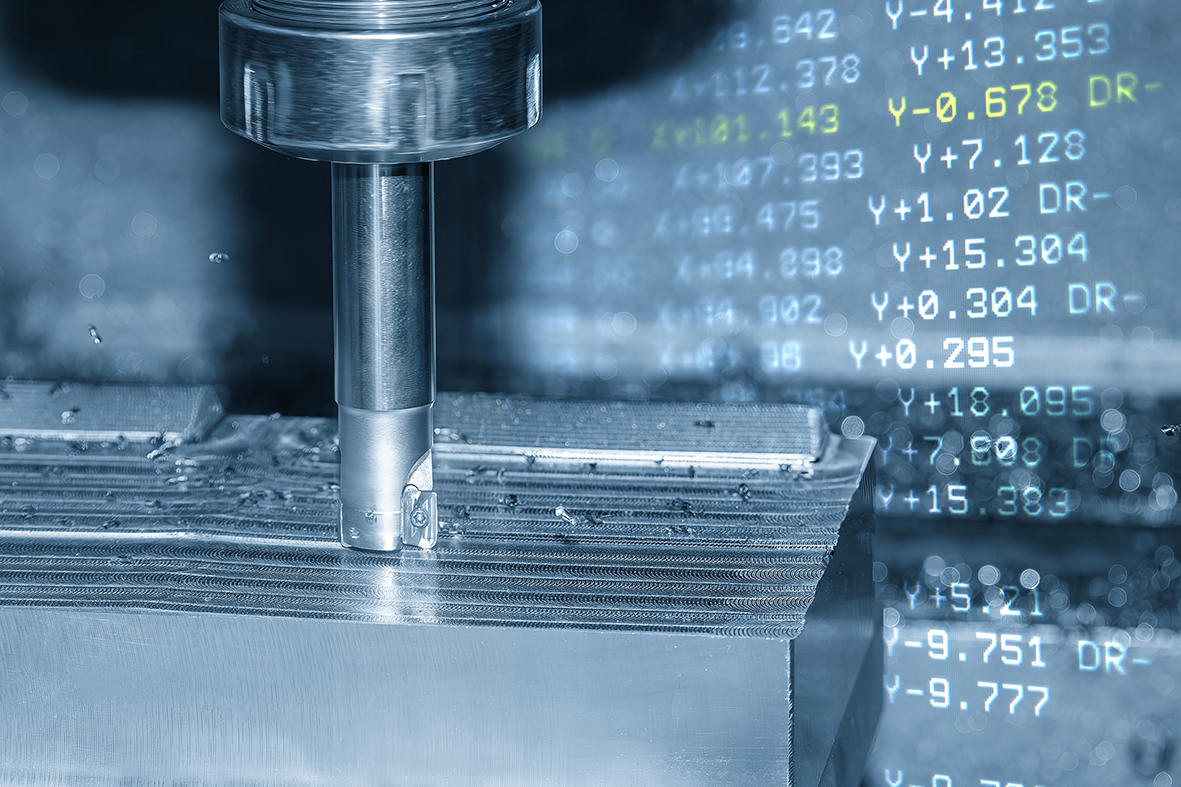

HER collet chuck toolholders are developed with structural stability as their core design philosophy. Rather than merely reinforcing individual components of conventional ER toolholders, HER rethinks the entire structural logic from the perspective of load distribution, clamping stability, and long-term reliability. This holistic optimization allows the toolholder to maintain stable clamping under high load and high-speed machining conditions, naturally achieving precision performance at the 5 µm level in real-world applications.