The main roles and functions of grinding wheel tool holders

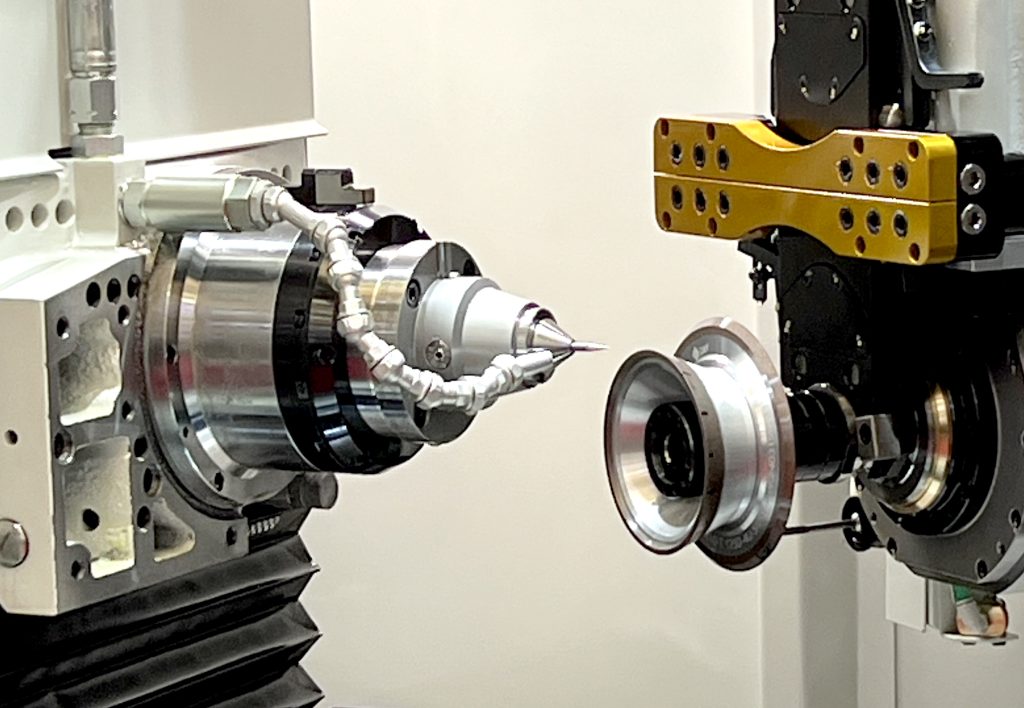

The grinding wheel tool holder used in CNC tool grinders is an important component for fixing and clamping the grinding wheel. It is mainly used to ensure that the grinding wheel is processed accurately on the grinder. Grinding wheel tool holders are usually made of high-strength metal and are designed to have sufficient rigidity and durability to cope with high-speed rotation and high-load processing environments.

The main function of the grinding wheel tool holder is to hold the grinding wheel to ensure that the grinding wheel does not fall off or move during the machining process. In addition, the grinding wheel tool holder also provides precise positioning to ensure that the grinding wheel can be processed according to the predetermined path to achieve the required size and shape. At the same time, it also needs to effectively transmit the power of the grinder spindle so that the grinding wheel can rotate stably, thereby achieving stable grinding results. Grinding wheel tool holders are available in a variety of designs and specifications based on different grinder types and processing needs.

For example, some designs are suitable for cylindrical grinding, and some are designed for internal cylindrical grinding or face grinding. No matter which type it is, the design of the grinding wheel tool holder needs to take into account the convenience of installation and adjustment to ensure machining accuracy and balance of the grinding wheel. These processes usually require professional and technical personnel to ensure the best processing results.

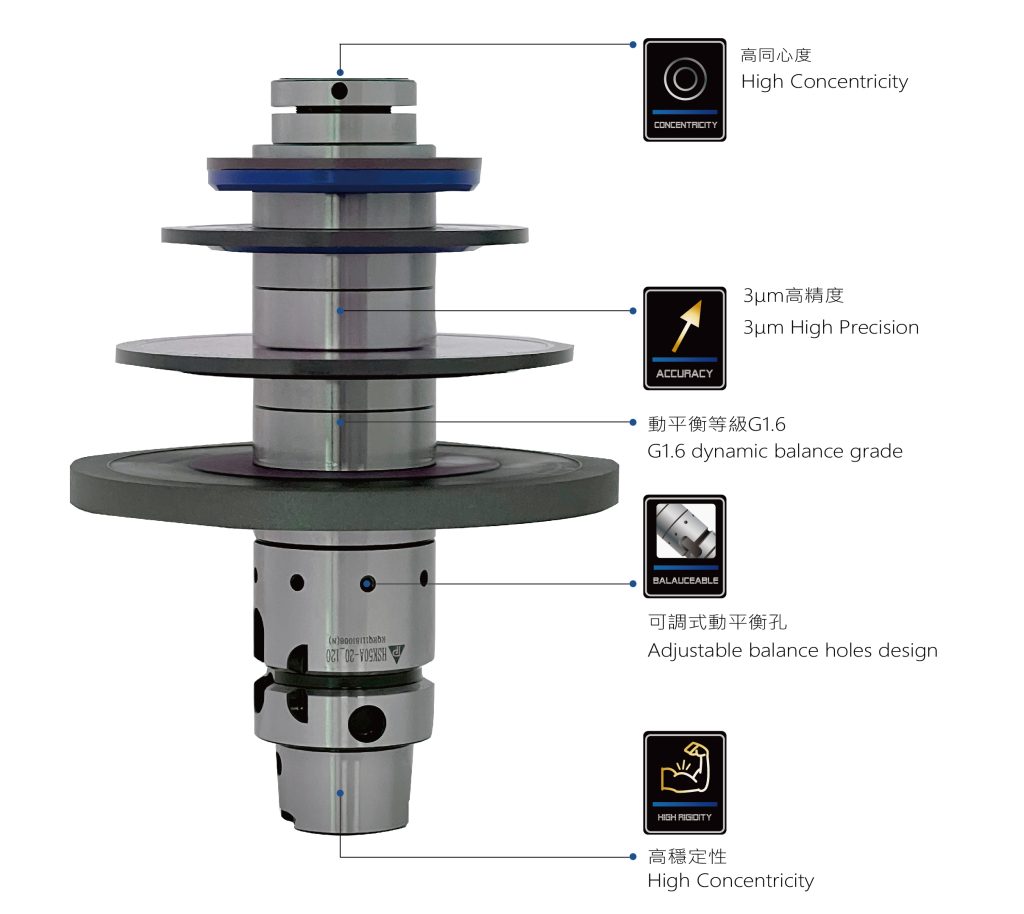

Advantages of Puhui grinding wheel tool holder:

‧ 3µm high precision (low deflection) – Improve machining quality, reduce vibration, improve work efficiency and improve safety.

‧ High concentricity– The one-piece design keeps the central axis consistent and avoids deviation from the center to ensure that the size of the processed parts meets the design requirements.

‧High stability – Good material selection and rigorous processing processes achieve high rigidity of the body and long service life of the product.

‧High dynamic balance level – G1.6 dynamic balance level and adjustable

The design of dynamic balancing holes reduces vibration during high-speed processing, thereby improving the stability and operating efficiency of the equipment.

Grinding wheel tool holder specifications and applicable brands

ANCA

HSK40F series: HSK40F 20 / HSK40F 31.75 / HSK40F 32

HSK50F series: HSK50F 20/HSK50F 31.75/HSK50F 32

WalterWALTER

HSK40F series: HSK40 32_034-20_033 / HSK40 20 / 32 / 31.75

HSK50F series: HSK50 20 / HSK50 31.75

NCT series:NCT 20/NCT 31.75

For detailed regulations, please refer to: Grinding Wheel Holder Cataloghttps://parfaite.com/app/uploads/flipbook/40/book.html

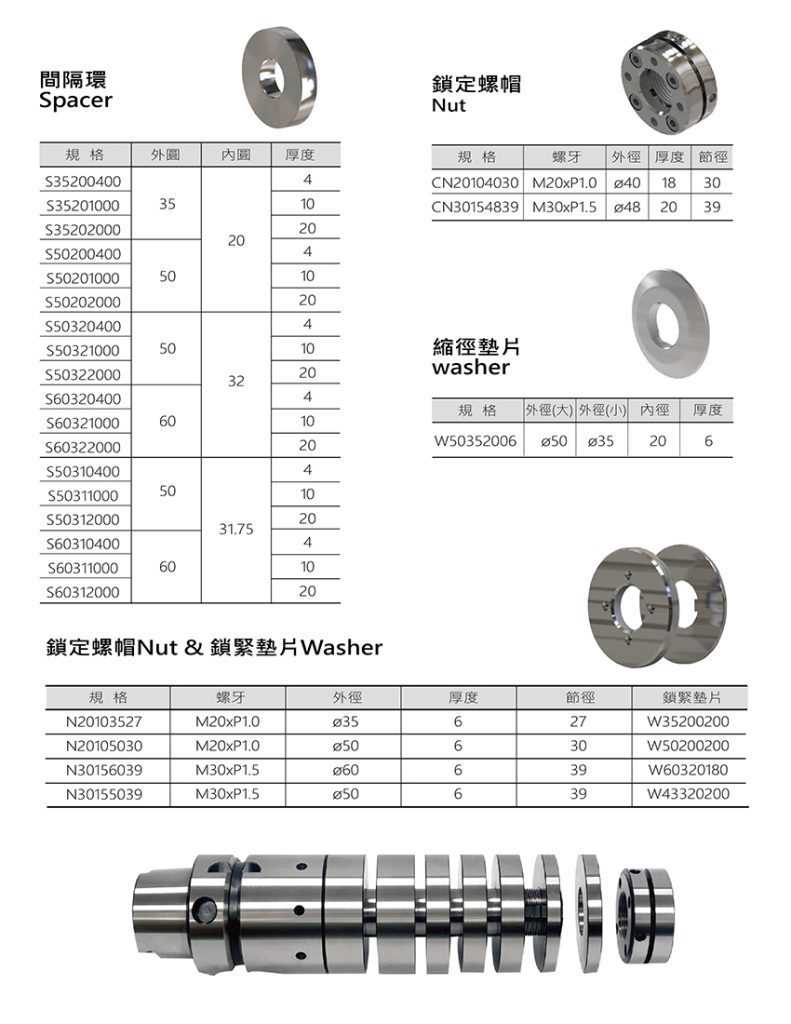

Main spare parts of grinding wheel tool holder