April 29, 2025

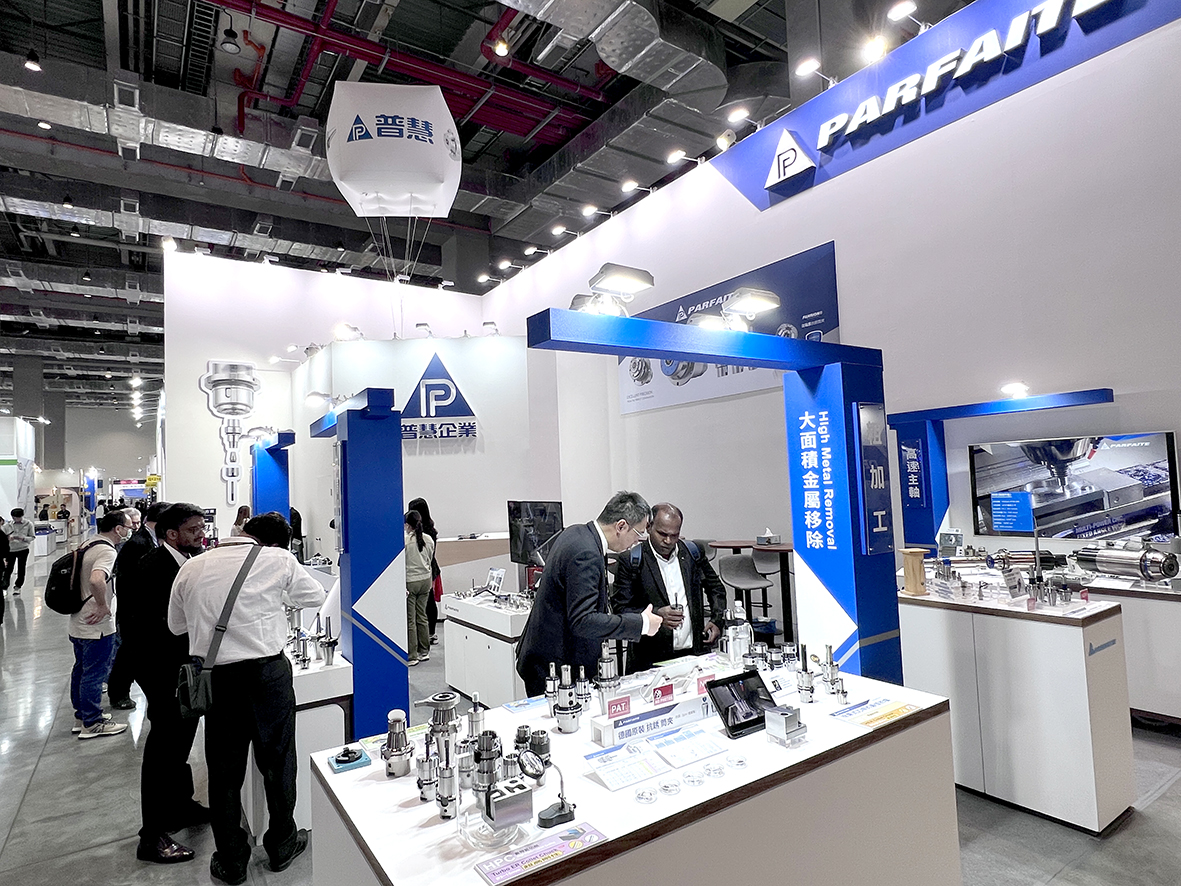

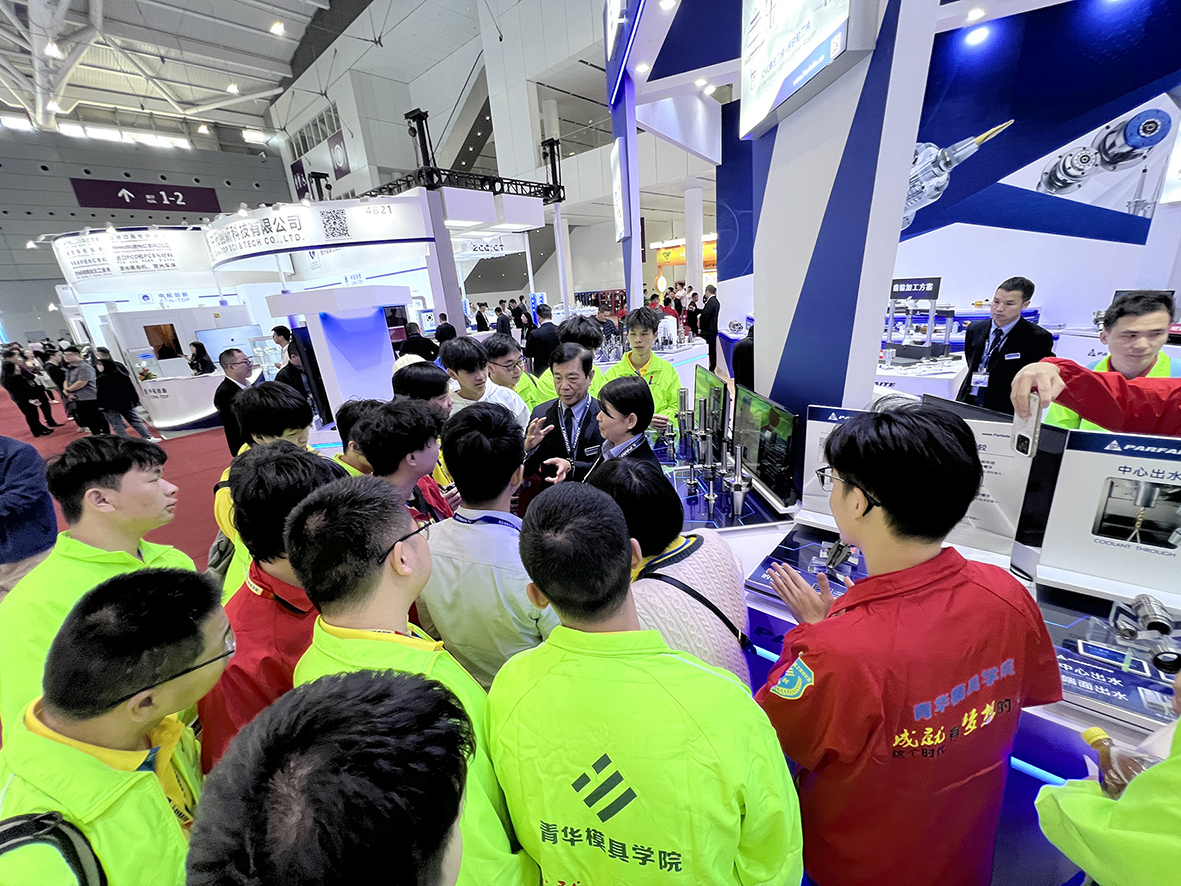

Thank you to all our customers and friends from all over the world for visiting and communicating with Puhui Enterprise at booth B2-011 in Hall B2 of Beijing Capital International Convention and Exhibition Center from April 21 to 26, 2025!