What is RFID? What is its development history and scope of application?

RFID is the abbreviation of "Radio Frequency IDentification" in English. It is called "Radio Frequency Identification System" in Chinese. It is a non-contact automatic identification system that can read and write tags with RFID. It is usually composed of sensors (Reader) and The system composed of RFID tags (Tag) operates on the principle of using the sensor to emit radio waves, touch the RFID tag within the sensing range, generate current through electromagnetic induction, supply the chip on the RFID tag to operate, and send out electromagnetic waves to respond to the sensor .

The commercial application of RFID began to germinate in the 1980s. Until today, the application of RFID is "ubiquitous" in life, such as shopping in shopping malls or convenience stores, borrowing books in libraries, taking transportation, paying parking fees, car washing, and electronic devices on highways. Charge "ETC", mail, identification card or go to the hospital to register to get medicine...all of them live with "you" like a shadow.

What is RFID tool management system?

With the rise of the concept of Industry 4.0 and smart manufacturing, information transparency and real-time data connection at the manufacturing site are extremely important to smart manufacturers, and RFID has been identified as a key technology. At present, in the manufacturing industry, RFID technology is mainly used to manage materials, machines and tools, and track the process, so as to improve the overall efficiency and effectively reduce operating costs.

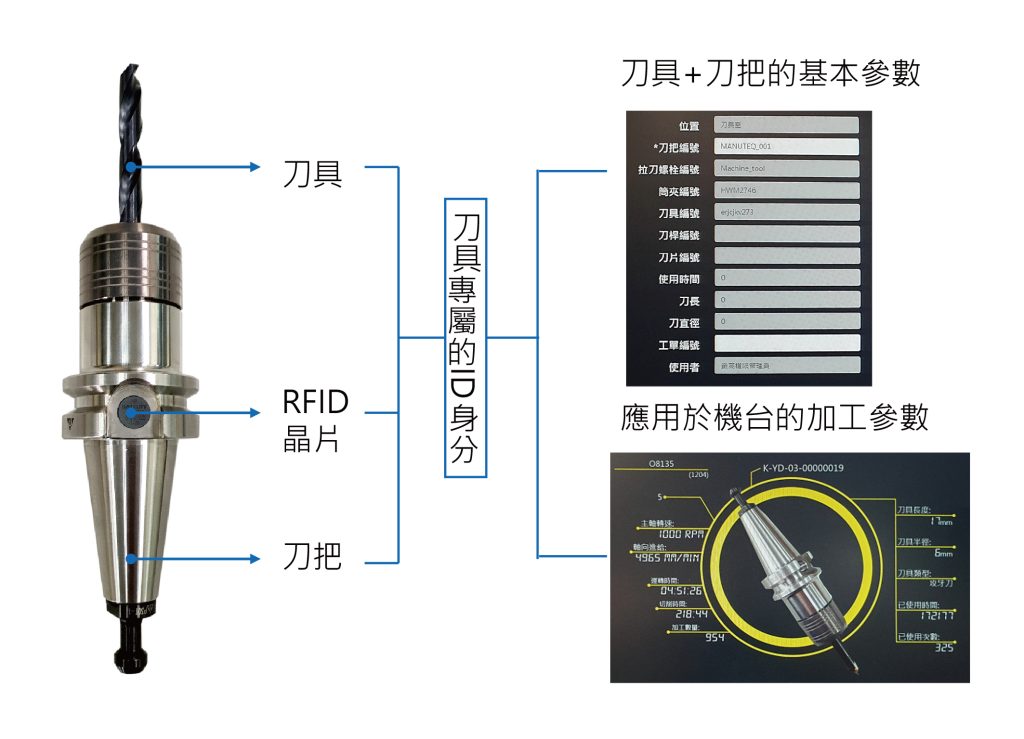

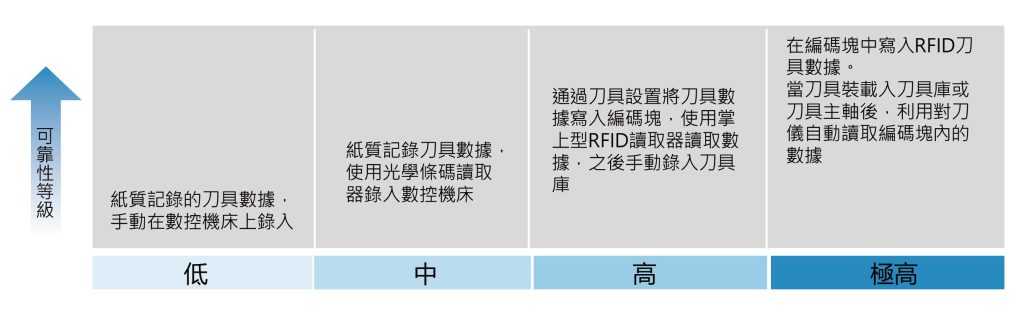

Tool management is an important part of CNC milling machine processing. In response to the trend of automation, digitization, and intelligence, and to get rid of the traditional manual recording method, Puhui Enterprise suggests that the tool management solution can be combined with BALLUFF's RFID tool identification system. The concept will beTool HolderThe chip combined with the tool equipped with RFID is equivalent to giving the tool an exclusive ID. Using this feature, you can grasp the processing history, optimize the production process, efficiently manage tool information, warehousing, and circulation in the factory. You can also write tool processing data into the controller. And real-time monitoring tool life. Through the safe and reliable system of RFID, the parameters of the tool are always stored in the data carrier (RFIDTag), which is convenient for traceability record and use management.

Introduction to the use of RFID tool management - construction, application, management

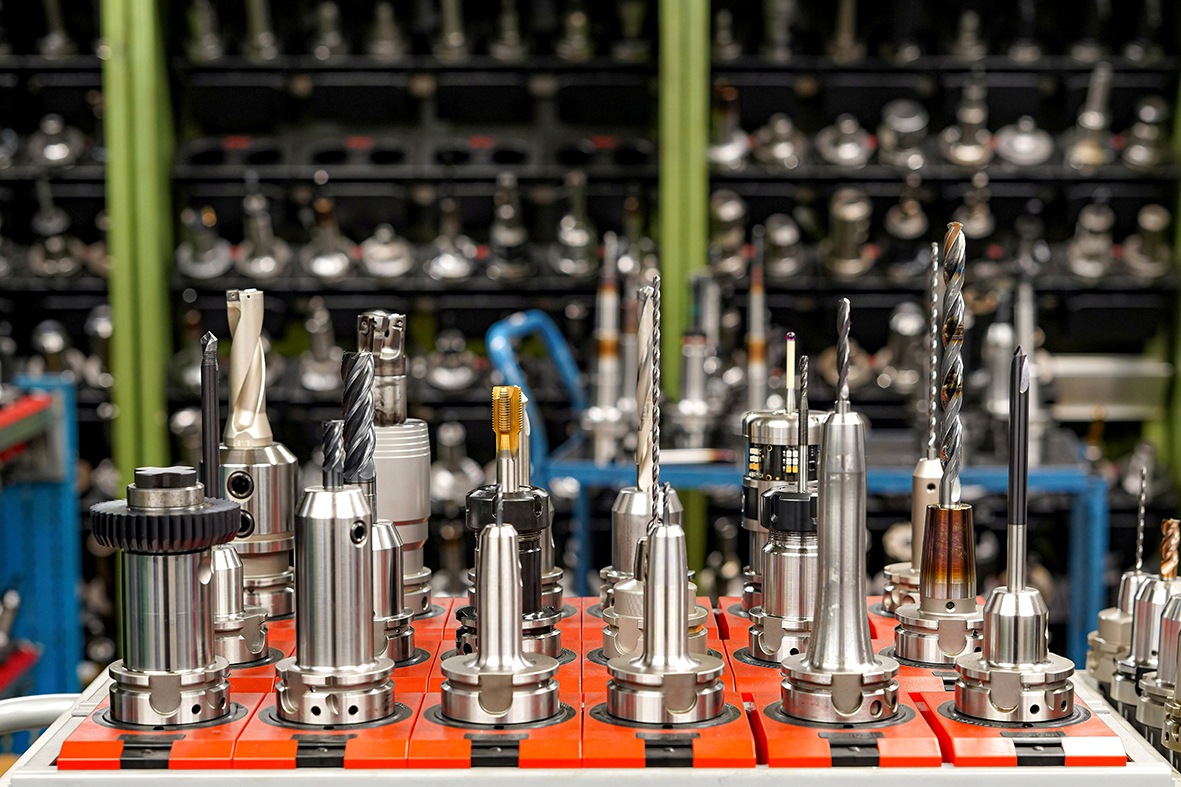

1. Create an exclusive ID:Using the RFID chip to build the basic information and processing parameters of the knife handle into the chip is equivalent to giving the knife handle an exclusive ID. Using this feature can grasp the processing history and optimize the production process.

2. Apply to the correct production process:

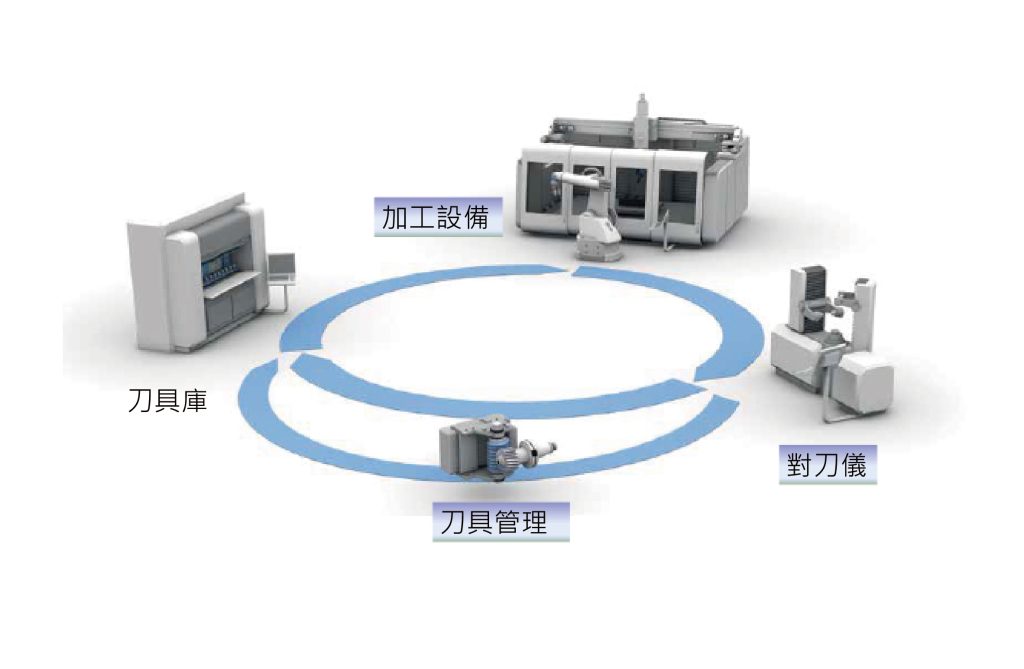

The flow chart below is a typical function block of tool management:

Tool measurement (with tool setter), tool transfer and tool storage, machine and tool monitoring, tool retooling (if necessary). The tool is bound to the RFID coding block so that the tool is always in the correct position throughout the production process.In this way, RFID ensures the high quality of machining and optimal utilization of tools, and also creates maximum value through this contactless data exchange.

3. Management of production history:

Complete tool parameters and reliable data communication and tool parameters are always stored in the data carrier (RFIDTag), which is convenient for traceability records and use management.

Fields more suitable for RFID tool management - mass production and automation

Modern production requires a higher level of automation. In order to meet the challenges of different production processes in metal processing, modern machine tools must automatically control and monitor the conveying of individual materials. This can be applied to both factory workpieces and machined tools. RFID provides real-time fast data exchange to meet these needs. The automatic acquisition of the system, the generation of documentation and the continuous monitoring of quality data allow the data to be read out at any time.

Hardware required for importing BALLUFF RFID tool management system

Tool management in metalworking machines is an integral part of automated processes. For many years, Balluff (Balluff) low-frequency RFID system is not only the industry standard, decades of industrial-grade RFID systems and professionalism. Its system provides reliable and complete tool data to support safe operations, thereby increasing factory productivity.

The following are the hardware required to import the RFID tool management system

1. Tool management smart column 2. Connector (for easy reading and writing) 3. Chip (chips must be installed for each knife) 4. Tool measuring instrument (need to be purchased by yourself)

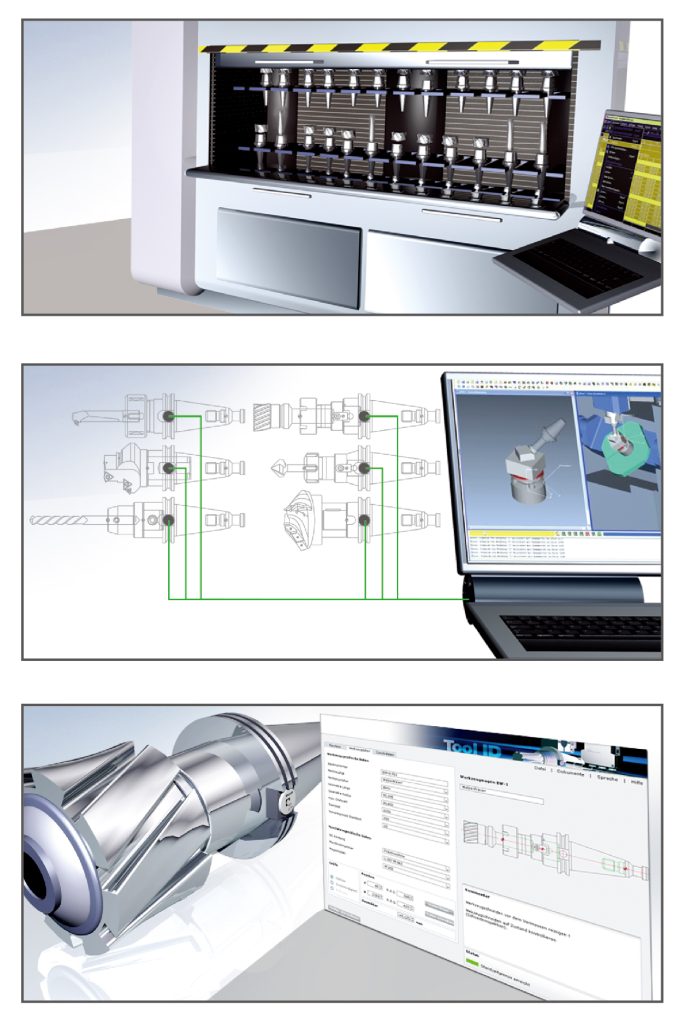

Introduction Tool Management Smart Columns and Connectors

● Tool Management Smart Column

The Smart Column is an integrated product that already includes:

Read/Write Head

Processor

Tool Holder

Power Supply and all other required components

● Connector (for easy reading and writing) Simplified configuration scheme for reading and writing chips

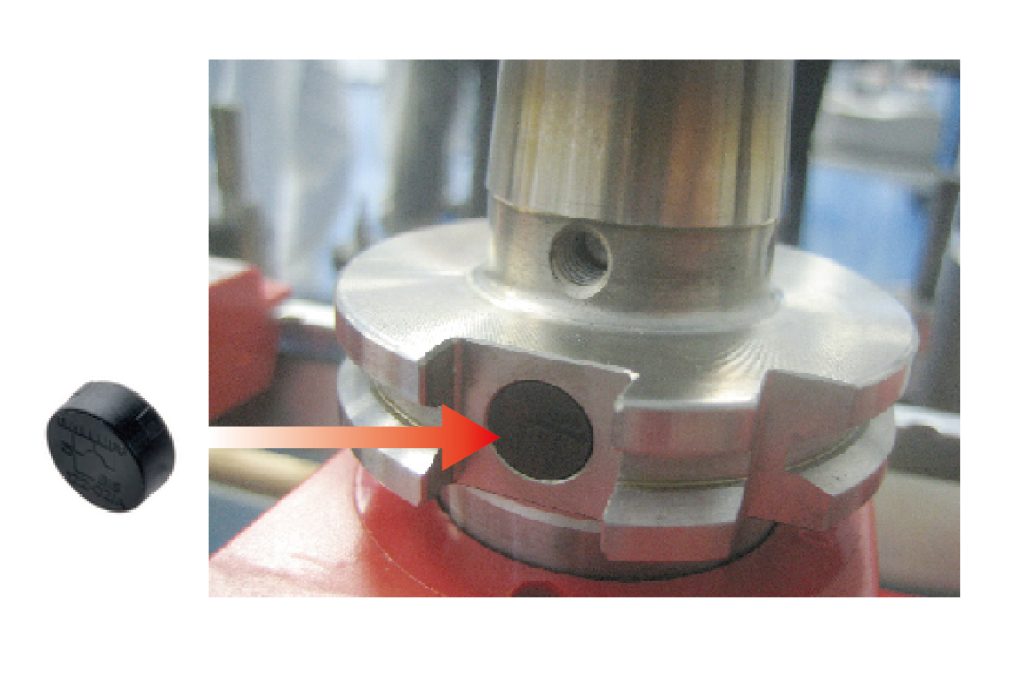

● Introduction chip (each knife must be equipped with a chip)

Ø 10×4.5 mm, readable and writable, capacity 511 bytes

rite life: 30 °C: 1000000 times 70 °C: 500000 times

Read lifetime: unlimited

Frequency: Low frequency (LF) is standard configuration, which is not easy to cause interference during metal processing

Advantages of special Tool handle RFID

Ⅴ Save overall cost

Ⅴ Functionality, scalability, future

Ⅴ Intelligent upgraded knife handle

Advantages of RFID tool management

The automatic processing of tool-specific data opens up new dimensions in tool management. To avoid manual input errors, RFID can continuously record tool information and automatically utilize tools during loading and unloading. The following are its advantages:

With optimal utilization (tool life management)

● Paperless tool information

● Correct and reliable data transmission

● Quality assurance and traceability records