Complete Guide to Cutting Tools: Boost Machining Efficiency by Choosing the Right Tool

1. Why CNC Cutting Tools Are the Key to Precision, Productivity, and Smart Machining?

In CNC machining—whether you're drilling, milling, or turning—cutting tools are at the core of every operation. They don’t just shape materials; they define how fast, how accurately, and how cost-effectively you can produce a part. The right tool boosts efficiency and consistency. The wrong one? It could mean scrapped parts, damaged machines, or delayed delivery.

That’s why mastering the selection and management of cutting tools is crucial—not only for professionals in the field, but also for anyone looking to understand the foundation of modern manufacturing.

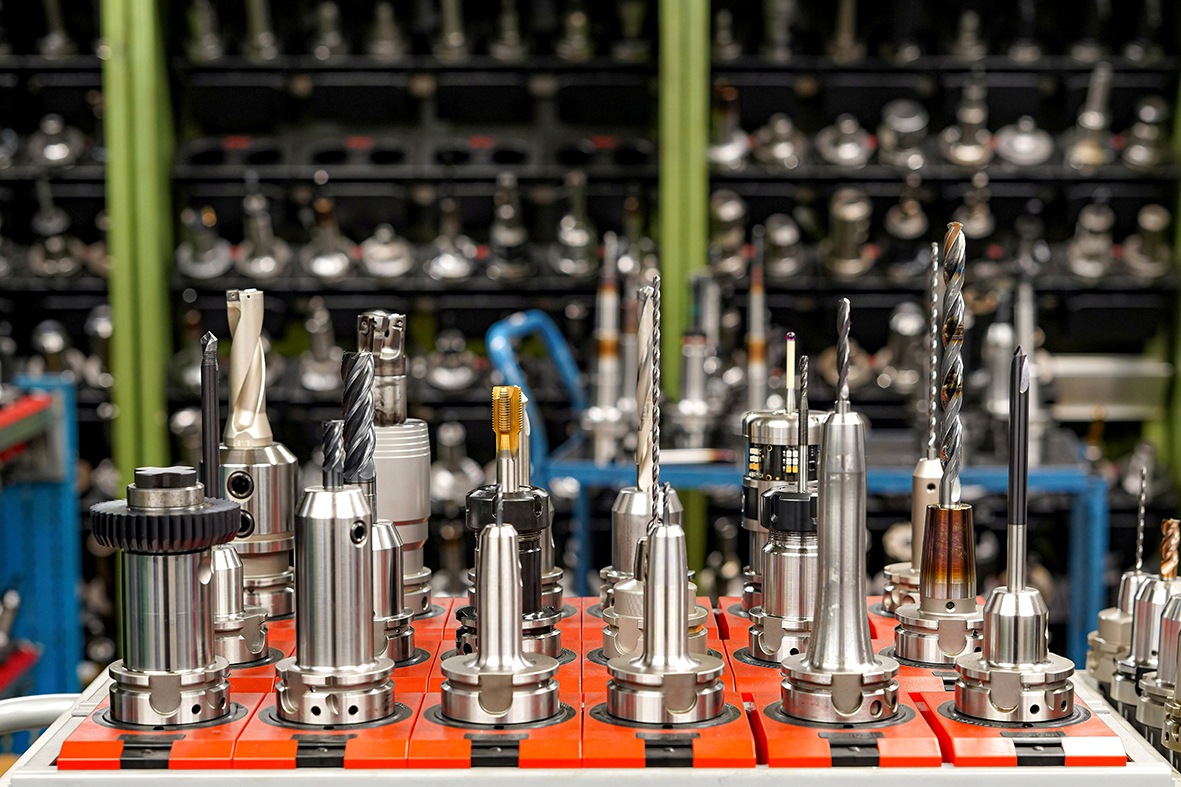

2.Know Your Tools: A Quick Guide to Common CNC Cutting Tools

Each machining process requires a different kind of tool. Here's a closer look at the most commonly used types:

Drill Bits – For hole making; often the starting point for CNC newcomers. End Mills – Versatile tools for milling surfaces, slots, and contours. Reamers – Used to fine-tune hole size and improve surface finish. Thread Mills – Ideal for cutting both internal and external threads with flexibility. Turning Tools – Applied on lathes for OD turning, facing, boring, and threading.

In any professional shop, choosing the right tool for the job—and using it correctly—is key to achieving consistent part quality and cycle time efficiency.

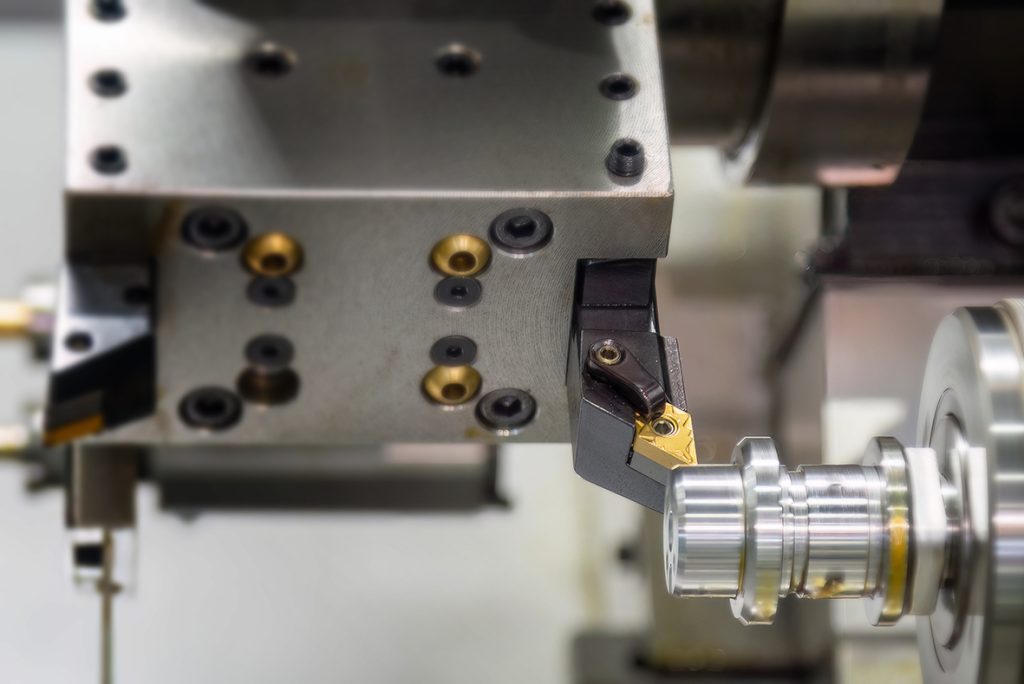

3. The Tool Holder: Your Foundation for Accuracy and Stability

A cutting edge is only as good as its holder. Without proper rigidity and balance, even the sharpest tool can fall short. The insert or cutting edge, which performs the machining The tool holder, which secures the tool in the spindle and transmits force accurately When a holder lacks proper clamping force or stability, it introduces vibration, offsets, or tool wear—compromising both precision and safety.

This Is Where Parfaite Comes In Hydraulic Tool Holders Parfaite’s high-precision hydraulic chucks use internal pressure chambers to clamp tools with 3μm concentricity. They're perfect for high-speed and high-precision tasks where vibration control is critical. HER Collet Chuck Holders Designed for both roughing and finishing, HER holders offer 5μm clamping accuracy and exceptional grip. Select models feature center-through coolant delivery, ensuring better chip evacuation and thermal control. pplication-Specific Holders Need a face milling tool holder? Tap adapter? Drill chuck? Parfaite offers specialized holders tailored to your operations—so every tool fits the task and runs flawlessly.

4. Material & Coating: The Golden Formula for Tool Performance

A tool’s material and coating have a significant impact on performance and lifespan.

High-Speed Steel (HSS) tools offer good toughness and are cost-effective, making them suitable for lower-speed applications. Carbide tools, with their superior heat resistance and hardness, are the current standard in CNC machining. For harder-to-machine materials, ceramic and CBN (Cubic Boron Nitride) tools are preferred due to their extreme hardness and thermal resistance.

Surface coatings such as TiN, AlTiN, and DLC improve wear resistance, reduce heat and chip adhesion, and increase overall tool durability.

By combining the right material with the right coating, manufacturers can significantly enhance productivity and consistency while reducing the risk of rework or scrap.

5. How to Choose the Right Tool: Fit Matters More Than Price

Choosing a cutting tool isn’t about picking the most expensive option—it’s about selecting the most suitable one for your process.

Start by considering the workpiece material. Aluminum requires sharp tools with efficient chip evacuation, while stainless steel or nickel alloys demand heat-resistant and tough cutting edges. Then, evaluate the machining method and depth. High-speed precision milling, deep-hole drilling, or complex multi-task operations all require specific tool holder systems and coolant-compatible tooling.

Using the wrong tool leads to poor efficiency, machine wear, and defective products. Professionals rely on proper tool selection based on material, speed, and clamping system to achieve optimal performance on the production floor.

6.Smart Tool Life Management: From Guesswork to Data

All cutting tools wear out over time but how do you know when to replace them? Relying solely on human judgment is risky and inconsistent.

Modern digital management offers a smarter solution. By integrating RFID (Radio Frequency Identification) chips into tool holders or adapters, each tool’s usage history, run time, and replacement data can be tracked automatically. When a tool nears the end of its life, the system provides alerts, helping prevent unexpected breakage, failed cuts, or machine damage.This shift from guesswork to data-driven decision making marks a key milestone toward smart manufacturing.

7. Conclusion: Cutting Tools Drive Competitive Advantage

From basic drilling to complex mold-making, every machining task relies on thoughtful selection and use of cutting tools. These tools are not merely consumables they are investments in quality, efficiency, and productivity.