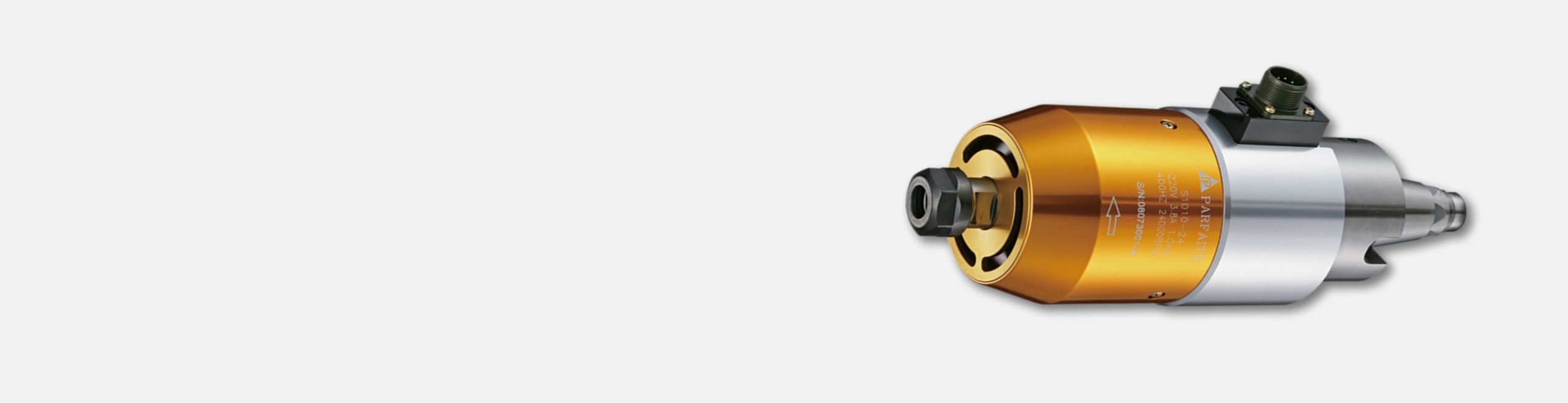

Speed Speeder

The installation is simple and doesn’t spend much time. As long as the general CNC machine is equipped with an electric speed increaser, it will immediately be upgraded to a CNC high-speed mold processing machine to achieve the goal of precision, stability, and high power. It’s an economic solution to greatly increase the spindle speed of the original machine to 60,000RM.

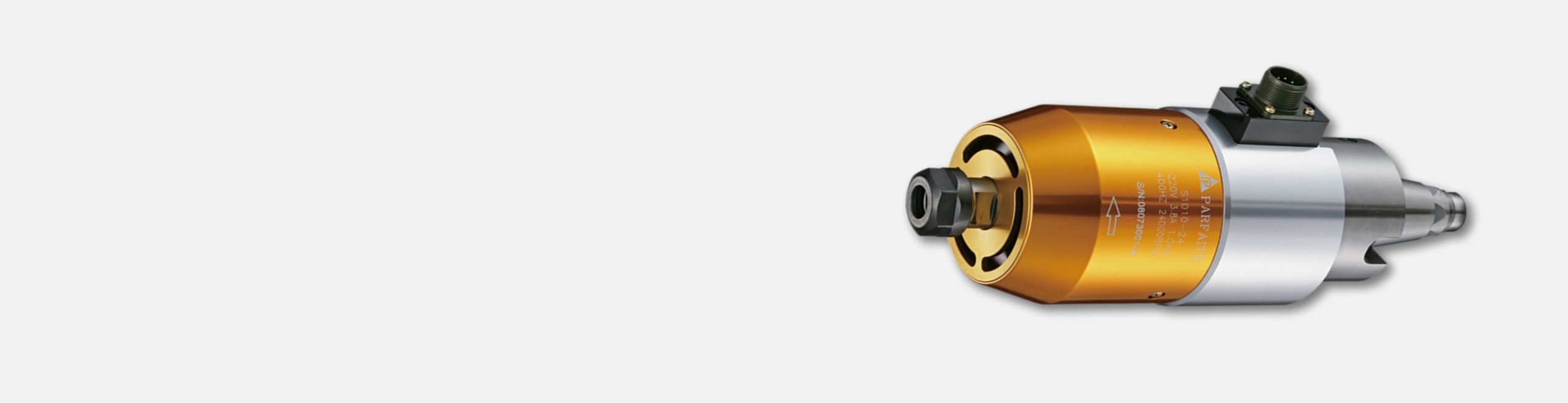

Speed Speeder

The installation is simple and doesn’t spend much time. As long as the general CNC machine is equipped with an electric speed increaser, it will immediately be upgraded to a CNC high-speed mold processing machine to achieve the goal of precision, stability, and high power. It’s an economic solution to greatly increase the spindle speed of the original machine to 60,000RM.

Technology

Product characteristics and technology

Speed up to 30,000 RPM

The speed of high-frequency motor can reach 30,000 rpm, and the main shaft of the machine doesn’t need to rotate. It can run for 24 hours without gear noise.

Low noise and low vibration

Since the main shaft of the machine does not need to rotate, it is driven by the motor of the spindle speeder, so the noise can be reduced and the processing can continue for 24 hours. The low vibration can ensure high quality of precision machining.

Good rigidity on both sides

Since the main shaft of the machine does not need to rotate, it is driven by the motor of the spindle speeder, so the noise can be reduced and the processing can continue for 24 hours. The low vibration can ensure high quality of precision machining.

High power

The design of high power and high torque can be easily processed on the steel after heat treatment. (Note: applicable for S1130)

Easy and quick installation

The installation is not complicated, it takes a few simple steps to complete the installation and doesn’t need to dismantle the machine.

It’s also applicable for extremely fine corner cleaning.

It can replace special electric discharge machining and eliminate the production of electrodes, and can process fine corner clearing work or higher precision machining.