Material

MATERIAL

It is very important for the material using to manufacture tool holders to increase the tool life and stability. The quality of material used in holders is less important than the accuracy and other properties, but the high grade material is good at not only the tensile strength or tenacity but also the outstanding and dense molecular structure. Better quality material with correct processing is able to extent the tool life under the same accuracy condition so that the products will not become "consumables".

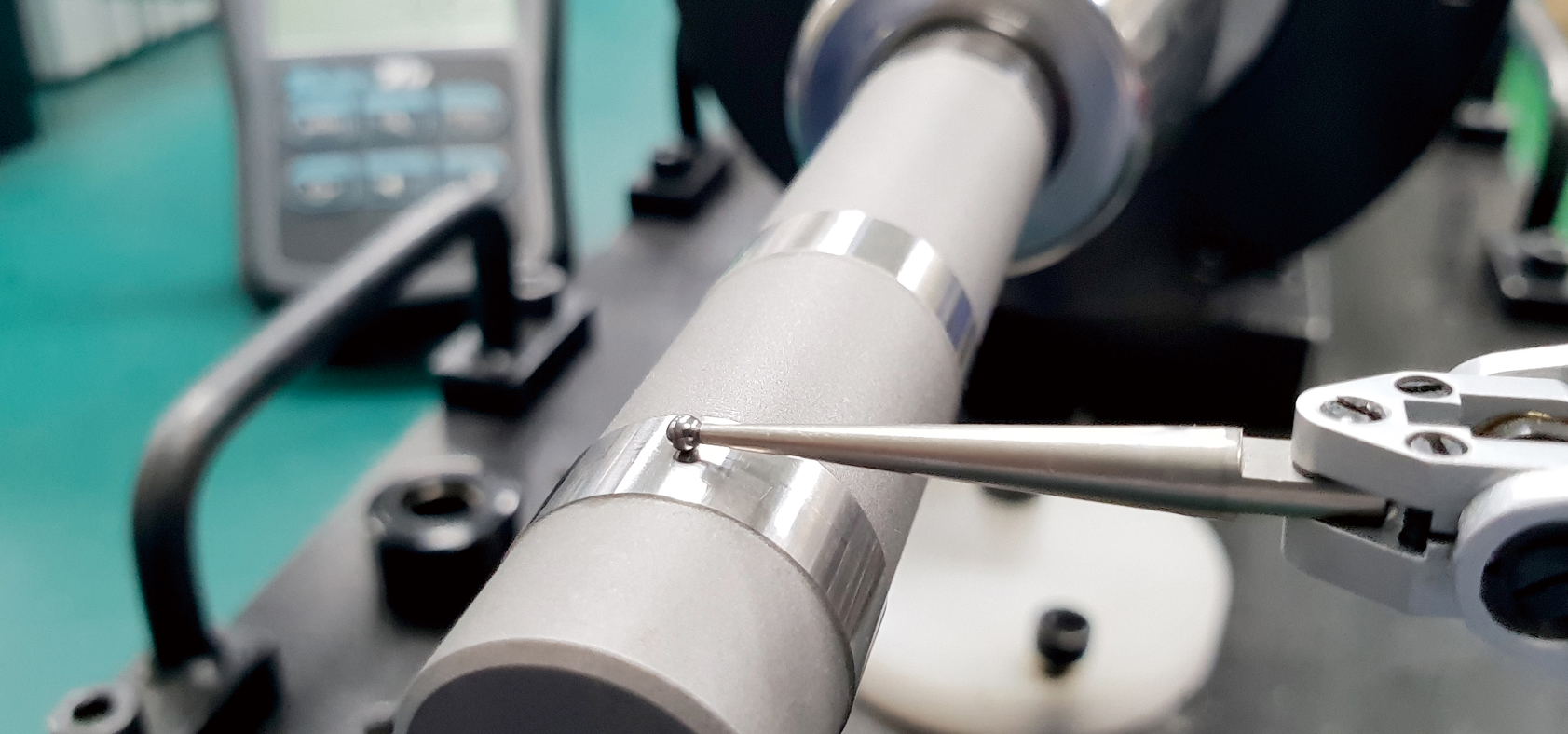

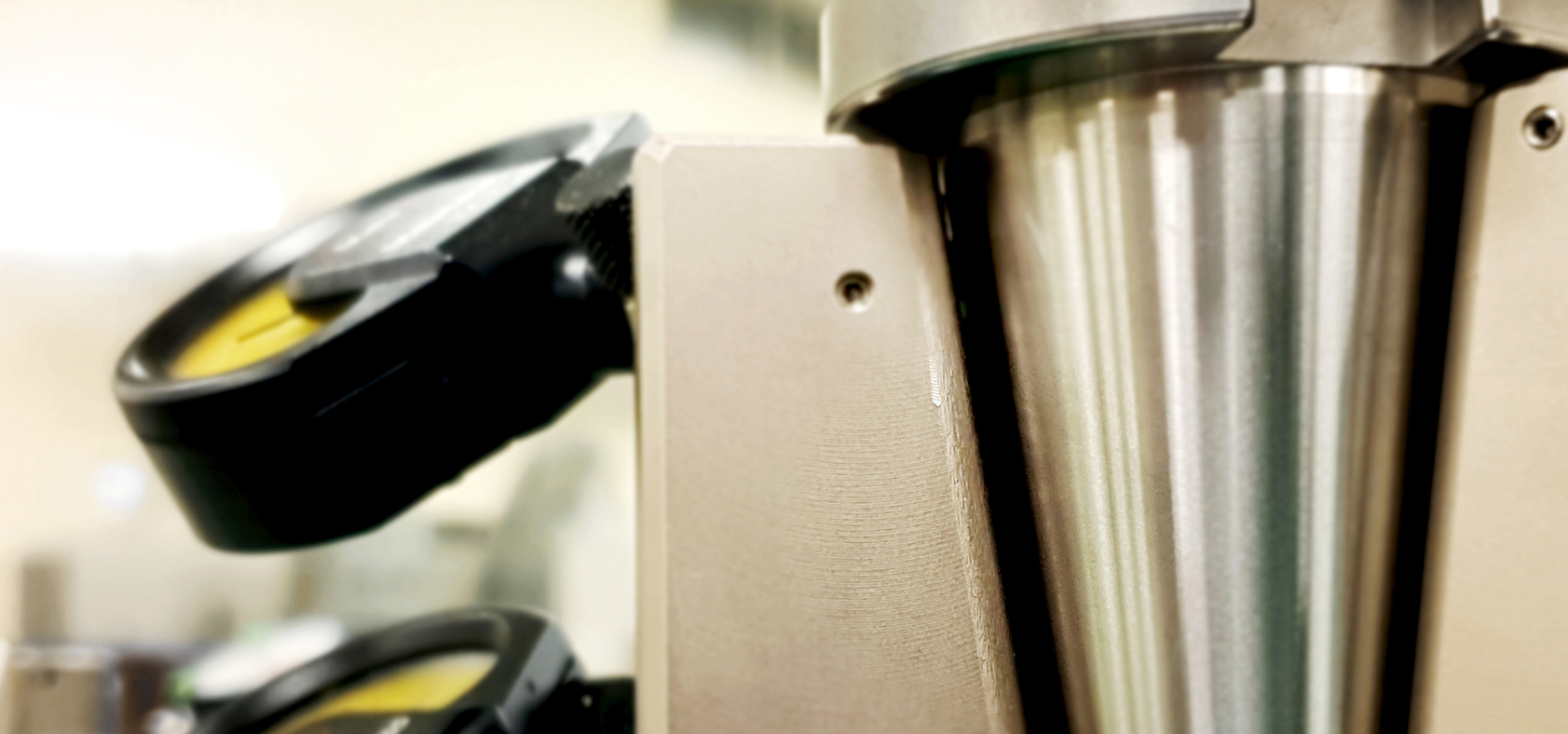

PARFAITE chooses material for tool holders from well-known European and American manufacturers to ensure the quality which customers put as first criteria. PARFAITE select Ni-Cr-Mo alloy compared with those in the industry who are price oriented choose Cr-Mo alloy used on low-cost ER collet or side lock BT tool holders. The Ni-Cr-Mo alloy steel has more dense molecular structure with nickel characters ( See the following picture of internal structures of Ni-Cr-Mo alloy and Cr-Mo alloy for comparison). Under the circumstance of raw materials prices are soaring the material cost is higher about 20% than general, however, the tool life and the accuracy are multiplied.

In other words the tolerance's stability of tool holders and be wear resistance will be increased the rate of deformation in the long term of harsh tool change and intensive processing will be decreased.