Comprehensive Guide to Tool Wear: Influencing Factors, Wear Mechanisms, and Life Management Strategies

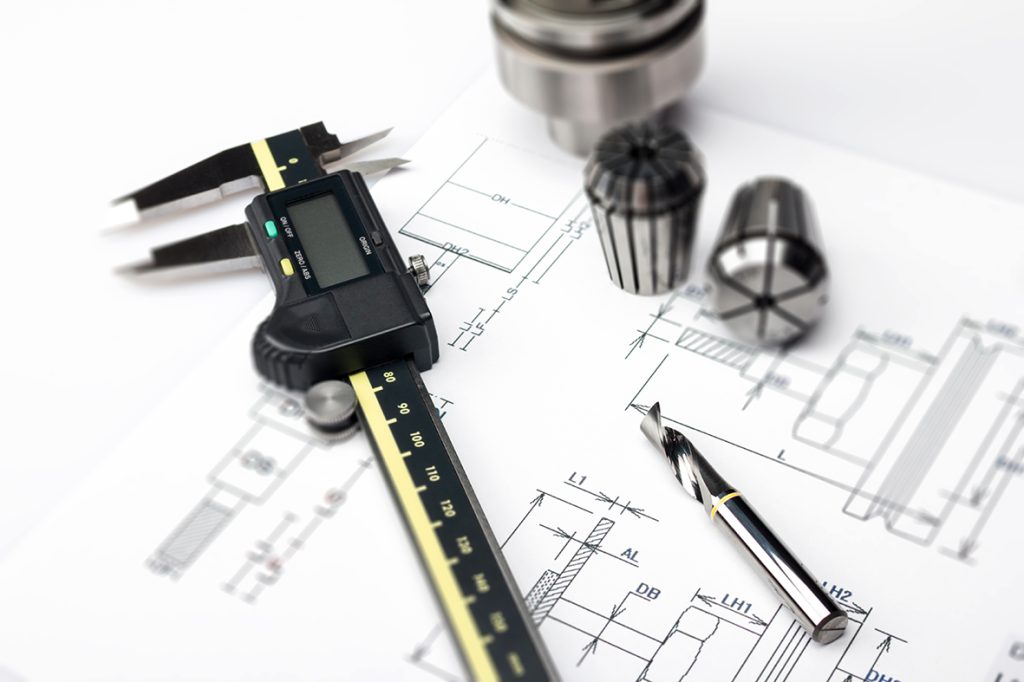

In CNC machining, tool wear is one of the most critical issues that cannot be ignored. It directly affects machining accuracy, surface roughness, cutting efficiency, and tool cost, and indirectly impacts the overall equipment utilization rate on the production floor. By understanding the mechanisms behind tool wear, identifying wear conditions, and applying effective preventive strategies, manufacturers can significantly improve machining stability while reducing long-term tool and equipment costs. This guide covers the impact of tool wear, causes, types, life-influencing factors, monitoring methods, and concludes with a recommended solution—PARFAITE HER High-Speed Collet Chuck Holders—to help you build a complete and practical tool-wear management strategy.

1. How Tool Wear Affects Machining Quality

Although tool wear develops gradually, its impact on machining quality can be substantial. Once the cutting edge becomes dull, the tool requires greater cutting forces to remove material, resulting in several issues:

Dimensional deviation: A worn tool often produces parts that are oversized or undersized, especially critical in high-precision machining where errors accumulate rapidly.

Poor surface roughness: A rounded or worn edge drags material instead of cutting it cleanly, causing chatter marks, scratches, or rough surfaces

Increased vibration: Uneven cutting caused by wear may trigger chatter, leading to premature chipping or edge failure.

Excessive heat: Deformed edges prevent proper heat evacuation, raising the risk of built-up edges or cracking.

Higher machine load: Spindles, holders, and tools endure greater stress, which may shorten machine lifespan over time.

Tool wear is therefore far more than simple material loss—it directly determines overall machining quality and process stability.

2. Causes of Tool Wear

Tool wear arises from a combination of material characteristics, cutting conditions, and equipment factors. Major causes include:

Excessive cutting heat: In high-speed machining, cutting temperatures can exceed 800°C, softening tool material and accelerating wear.

High cutting forces: Excessive feed rates, hard workpiece materials, or insufficient tool rigidity generate heavy cutting loads.

Material properties: Stainless steel, titanium alloys, and nickel alloys tend to work-harden, rapidly dulling cutting edges.

Inappropriate tool material or coating: Each material requires suitable substrate and coating combinations; a mismatch leads to rapid wear.

Inadequate cooling: Incorrect coolant direction or flow prevents effective heat dissipation, increasing the risk of built-up edges.

Inappropriate tool material or coating: Each material requires suitable substrate and coating combinations; a mismatch leads to rapid wear.

Identifying the root causes helps operators fine-tune machining conditions and extend tool life.

3. Common Forms of Tool Wear and Countermeasures

Tool wear can be categorized based on the wear location and appearance, with different impacts on machining quality.

1. Edge rounding (normal flank wear): The most common wear type, leading to dimensional inaccuracy.

Solution: Reduce feed rate, improve cooling, use more wear-resistant coatings.

2. Crater wear:Occurs on the rake face due to high cutting temperature and shear stress.

Solution: Lower cutting speed, apply heat-resistant coatings such as AlTiN, increase coolant efficiency.

3. Chipping:Edge fragments break off, typical when machining hard or brittle materials or when vibration occurs.

Solution: Increase clamping rigidity, use tougher tool grades, reduce machining chatter.

4. Built-up edge (BUE):Workpiece material adheres to the cutting edge, causing rough cutting and accelerated wear.

Solution: Increase cutting speed, improve cooling, apply coatings suitable for aluminum or stainless steel.

5. Thermal cracking:Rapid temperature fluctuations produce cracks across the cutting edge.

Solution: Avoid drastic thermal cycles, stabilize coolant application, reduce cutting load.

4. Key Factors Affecting Tool Life and Wear

Tool life is determined not only by the tool itself but by the overall machining system. The most important influencing factors include:

1. Tool material and coating technology

Different tool materials offer different levels of wear resistance, heat resistance, and toughness:Carbide: High wear resistance for high-speed machining High-speed steel (HSS): High toughness, ideal for interrupted cutting Coatings (TiAlN, AlCrN, DLC, etc.): Improve thermal resistance and material compatibility Selecting proper material and coatings can increase tool life by 20–100%.

2. Cutting parameters (speed, feed, depth of cut)

Excessive cutting speed drastically increases cutting temperature, accelerating wear. Imbalanced feed or cutting depth causes abnormal or localized wear.

3. Workpiece material characteristics

Stainless steels, titanium alloys, and high-nickel alloys tend to work-harden, requiring high-rigidity tool holders and appropriate coatings to slow down wear.

4. Toolholder rigidity and runout accuracy

Poor clamping stability creates micro-vibrations, doubling the wear rate. This is why high-precision, high-rigidity toolholders are critical for wear control.

5. Cooling and cutting fluid delivery

Effective cooling depends not just on having coolant, but on angle, pressure, and flow reaching the cutting point.

6. Machine rigidity and spindle condition

Worn spindle bearings or backlash create vibrations that transmit through the toolholder and accelerate wear.

5. How to Monitor Tool Wear

Effective monitoring prevents catastrophic tool failure and ensures machining consistency:

Dimensional checks: Track part size deviations over time.

Surface roughness inspection: Sudden roughness increase often signals wear.

Cutting sound changes: Abnormal sharp or uneven sounds indicate wear progression.

Spindle load monitoring: Rising spindle load is a sign of a dull tool.

Optical inspection: Microscopes or camera systems help examine edge condition.

Proactive detection improves productivity and reduces unexpected downtime.

六、推薦普慧HER Collet Chuck Holders:降低刀具磨耗的最佳解方之一

Among all factors influencing wear, toolholder performance is often underestimated. In reality, clamping quality is one of the most important elements in tool-wear control.

The PARFAITE HER High-Speed Collet Chuck Series offers outstanding clamping precision and dynamic balance, directly improving tool wear performance. Key advantages include:

1. Ultra-low runout for extended tool life

With ≤5 μm runout accuracy, HER holders ensure uniform cutting forces, preventing localized wear and chipping, significantly extending tool life.

2. Strong clamping force with reduced micro-vibration

High rigidity minimizes machining vibration, providing smoother cutting, more consistent wear, and improved surface finish.

3. Optimized for high-speed machining

Factory-balanced design supports high-RPM machining, improving efficiency while reducing thermal load on the tool.

4. Improved machining accuracy and stability

Users consistently experience better surface integrity, longer tool durability, and higher overall productivity when using HER high-speed holders.

Mastering Tool Wear Management = Mastering Machining Competitiveness

Tool wear is not an unavoidable problem—it is a process that can be fully controlled through data-driven monitoring, high-rigidity tooling, optimized machining parameters, and precision toolholders.If you aim to reduce tool costs, improve stability, and minimize downtime, investing in high-precision, high-rigidity holders such as the PARFAITE HER High-Speed Collet Chuck is a crucial step toward achieving efficient and reliable machining.