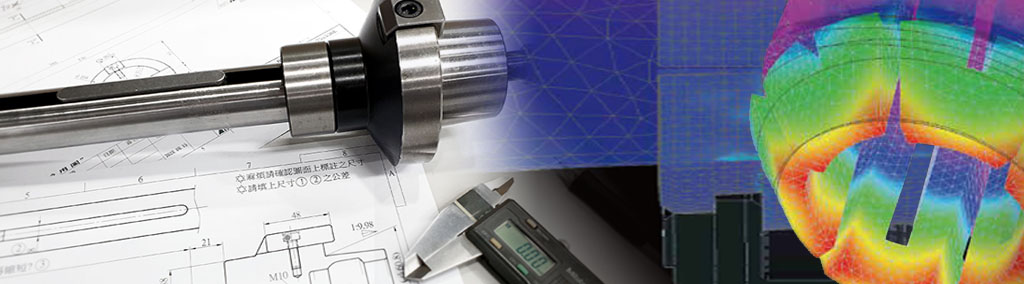

Customized service

With many years of manufacturing technology and practical experience in the production of spindles, tool holders and special tools, we can better understand the processing problems of customers with many special conditions, especially in the areas that can be solved by tool holders and tools. Welcome to provide processing purposes, drawings, and the data, we will evaluate the best plan by professional technicians to help customers solve the processing bottleneck. From the design of non-standard products to the service of improving production efficiency and reducing overall production costs, we have good capability and reputation in related industries such as automobiles, motorcycles, precision molds, transportation, aerospace... etc.

Customized service

Multi-step size forming boring cutter

The boring tool holder series include MAS, BT, HSK and other various main tool holders, fine-tuning boring tools, blade holders, side shank tool holders, elastic tool holders, and bridge arms for large hole processing. All special tool holders could meet the needs of various holes and processing planes.

Multi-step size forming boring cutter

The boring tool holder series include MAS, BT, HSK and other various main tool holders, fine-tuning boring tools, blade holders, side shank tool holders, elastic tool holders, and bridge arms for large hole processing. All special tool holders could meet the needs of various holes and processing planes.

Special tool holder for turning and milling machine

The boring tool holder series include MAS, BT, HSK and other various main tool holders, fine-tuning boring tools, blade holders, side shank tool holders, elastic tool holders, and bridge arms for large hole processing. All special tool holders could meet the needs of various holes and processing planes.

Special Service of Customized Tool Holders

Demand Diagnosis and Analysis

Through the discussion and understanding of customer needs, we can guess the requirements from the customer’s view. Then PARFAITE will adjust and analyze the special situation and provide professional opinions based on the experience of successful cases. During the interaction of customers and manufacturers, the problem will become clear and specific.

Product Planning and Discussion

Since the product design must fully determine the structure and specifications of the entire product system, the planning stage is very significant. PARFAITE will propose customized product specifications, materials, processing conditions, and design proposals based on the results of the discussion and customer needs, to make the product function better and the comprehensive competitiveness enhanced.

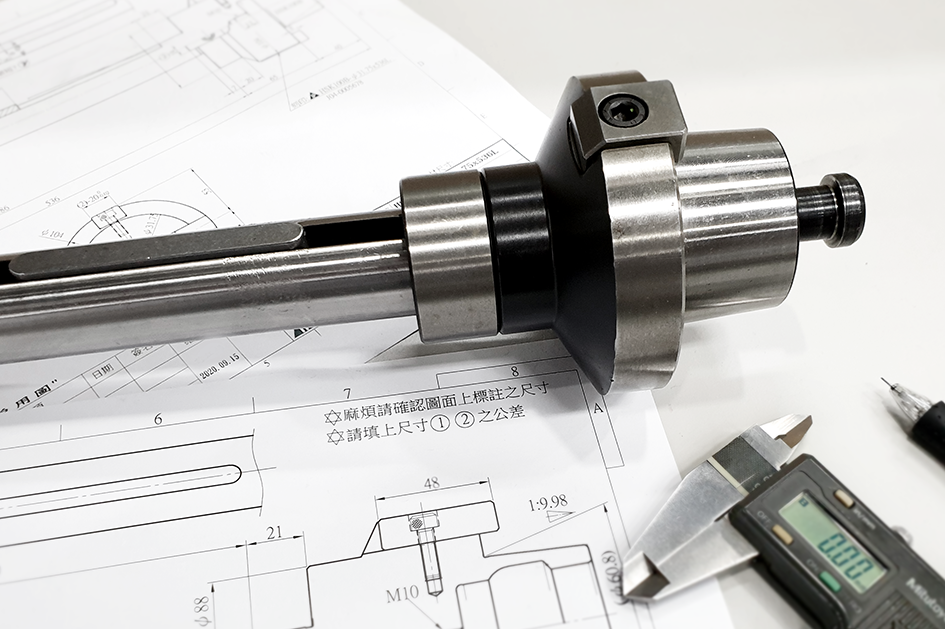

Design and Execution

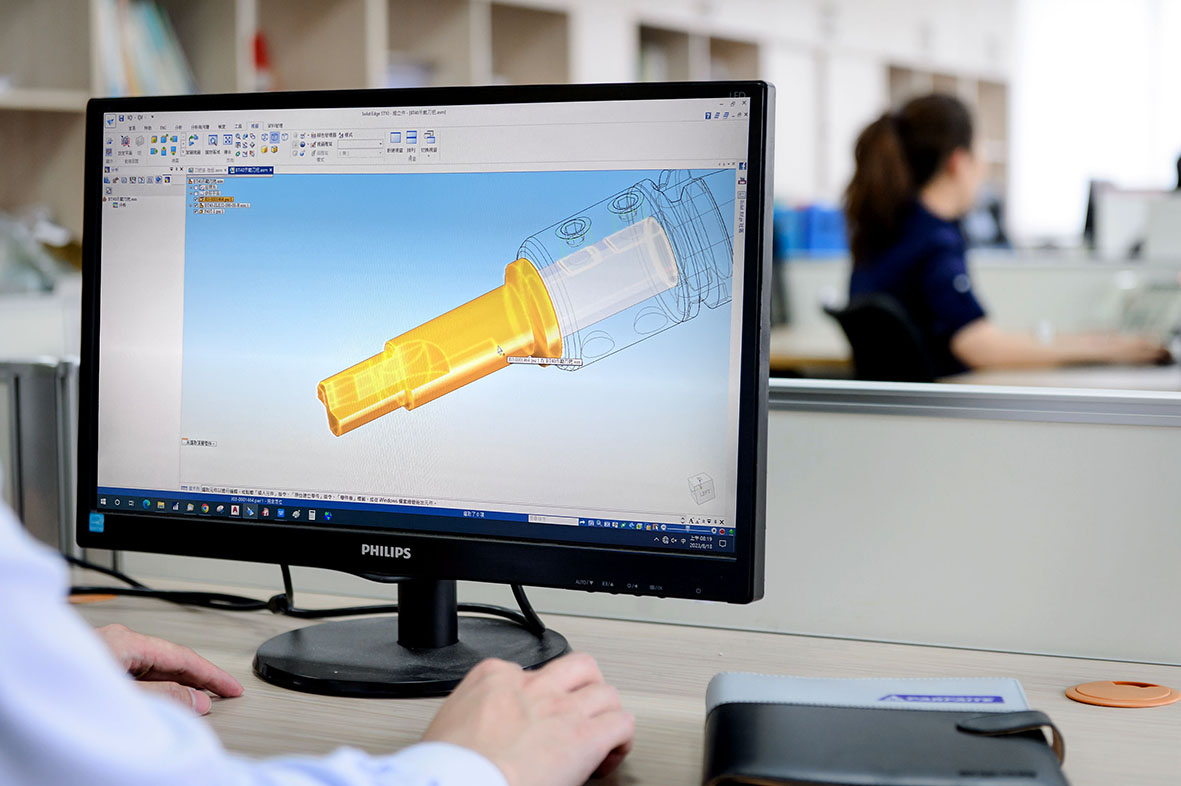

Through the communication and evaluation by professional design department and senior engineers, the engineers use computer-assisted analysis and design, execute simulation programs, and establish various specifications for production steps, and finally integrate and make design drawings to make the next execution smoother.

Professional production

After the drawing is checked, it will be passed to the production department to strictly control the quality and detailed production plan. After a series of quality control, each component is accurately assembled, and the finished product is tested again to measure and ensure other performance specifications. All procedures are for the best quality of the company's products, and to complete high-precision products for our customers.

Special Carbide Tool

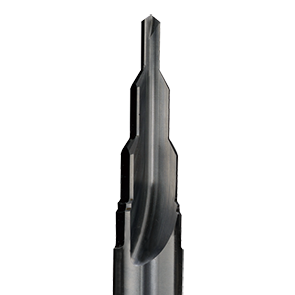

Multi-step size forming boring cutter

Multi-step size one-time forming drill

Six-blade precision milling cutter, large and small holes are formed at one time

Special Service of Carbid Tools

Demand Diagnosis and Analysis

Through the discussion and understanding of customer needs, we can guess the requirements from the customer’s view. Then PARFAITE will adjust and analyze the special situation and provide professional opinions based on the experience of successful cases. During the interaction of customers and manufacturers, the problem will become clear and specific.

Product Planning and Discussion

Since the product design must fully determine the structure and specifications of the entire product system, the planning stage is very significant. PARFAITE will propose customized product specifications, materials, processing conditions, and design proposals based on the results of the discussion and customer needs, to make the product function better and the comprehensive competitiveness enhanced.

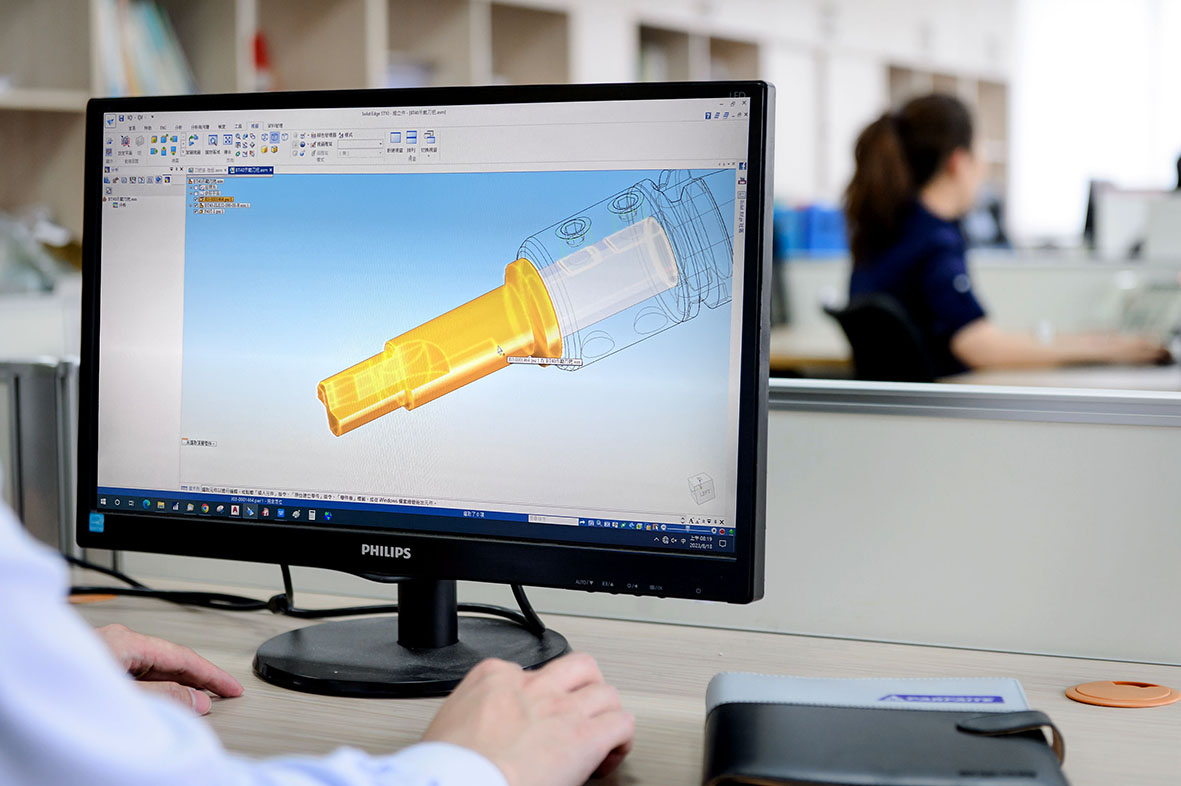

Design and Execution

Through the communication and evaluation by professional design department and senior engineers, the engineers use computer-assisted analysis and design, execute simulation programs, and establish various specifications for production steps, and finally integrate and make design drawings to make the next execution smoother.

Professional production

After the drawing is checked, it will be passed to the production department to strictly control the quality and detailed production plan. After a series of quality control, each component is accurately assembled, and the finished product is tested again to measure and ensure other performance specifications. All procedures are for the best quality of the company's products, and to complete high-precision products for our customers.