What are the differences between BT and BBT tool handles (tool holders)? Tool handle handle part

What is a BBT tool holder (tool holder)?

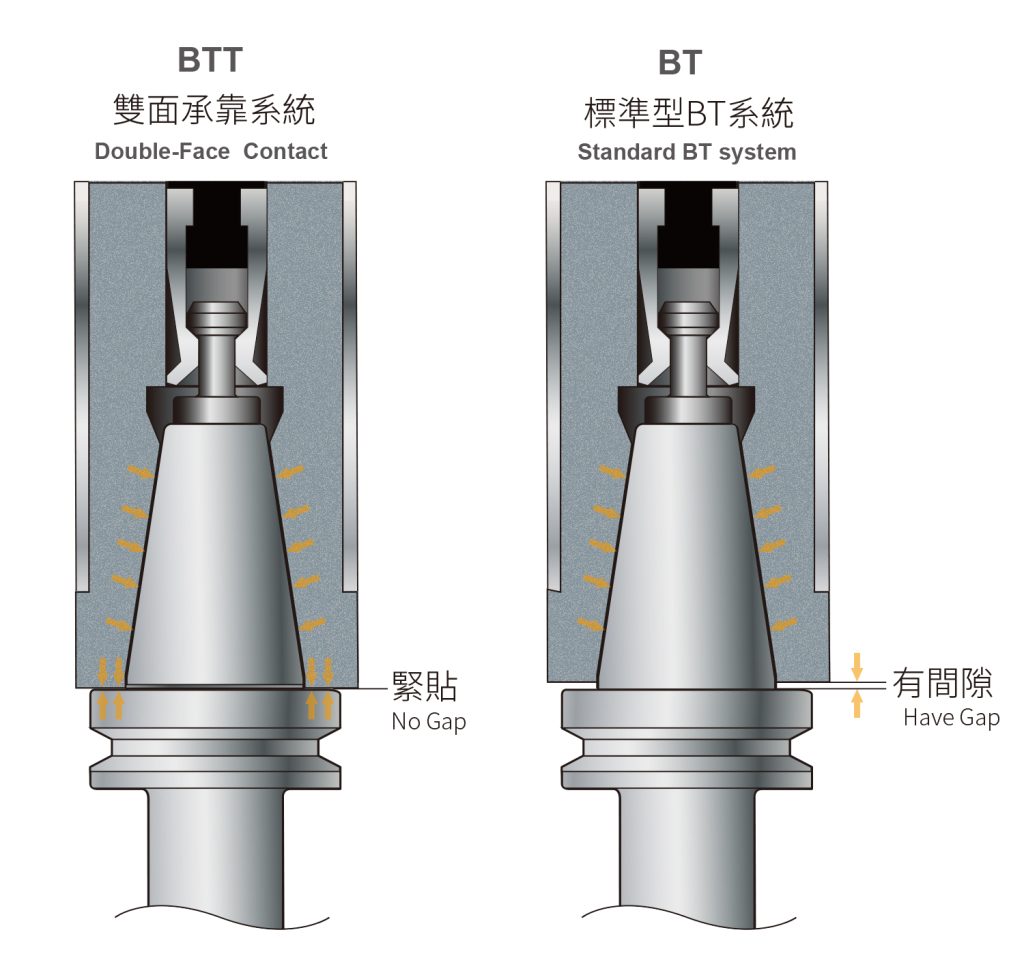

BBT tool holder (tool holder) is an improved BT tool holder system. In addition to the basic 7:24 taper specification, a flange surface contact design is added, which is an optimized design for double-sided support (taper contact and flange surface contact). , providing the clamping system with higher rigidity and stability. In order to distinguish it from the brands on the market, Puhui named the series after BTT, so the BBT knife handles on the market are Puhui's BTT knife handle series.

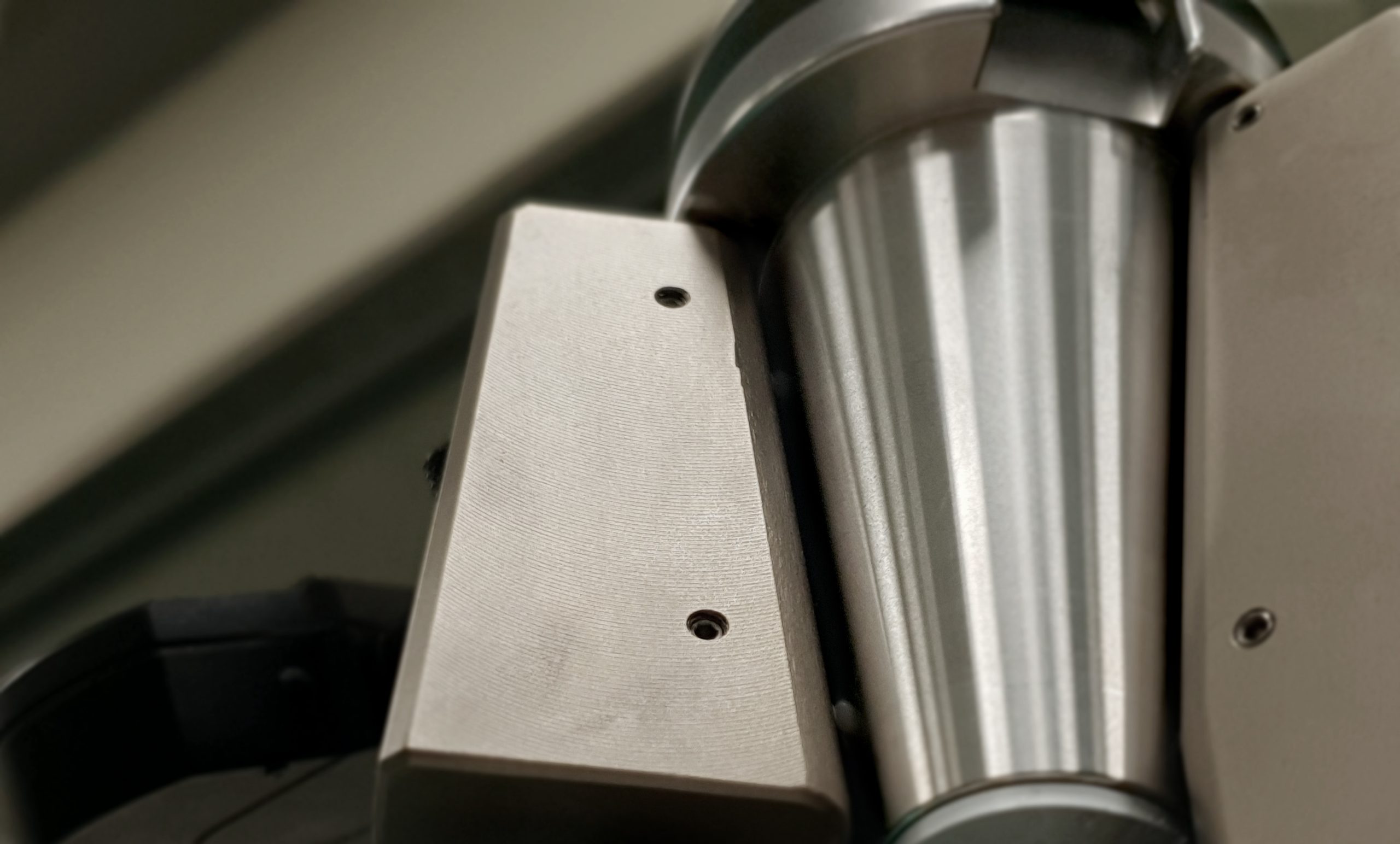

In addition, we can simply distinguish the BT tool holder and the BTT tool holder in terms of appearance. That is, because the flange surface of the BTT tool holder needs to bear on the spindle surface, there needs to be a clearance design at the middle junction. Due to the manufacturing process, a circle of black is retained. The escape area is a simple way to identify the BT tool holder and the BTT tool holder.

What are the differences between BT and BBT (BTT) tool holders (tool holders)?

1.design and structure:

BT knife handle: BT tool holder is a standard 7:24 taper design, mainly used in traditional CNC machine tools. The toolholder of this design is clamped by the taper contact with the machine tool spindle.

BTT knifeBundle: The BTT tool handle is an improved version of the BT tool handle. It has a double contact surface design, that is, in addition to the taper contact, there is also a flange surface contact. This design provides higher rigidity and better clamping stability, suitable for high-precision and high-speed processing needs.

2. Rigidity and stability:

BT tool holder: Due to only taper contact, the rigidity and stability of the BT tool holder are relatively low, especially in the case of high speed and heavy cutting.

BTT knifeBundle: The design of double contact surfaces provides higher rigidity and stability, can better cope with high speed and heavy cutting, and improves processing accuracy and surface quality.

3.Clamping accuracy:

BT tool holder: The clamping accuracy is average and suitable for conventional processing requirements.

BTT tool holder: Due to the design of double contact surfaces, the clamping accuracy is higher, which helps to improve the dimensional accuracy and surface quality of the workpiece.

From the above comparison, it can be seen that the BBT tool holder provides higher rigidity and stability in design, making it more suitable for demanding processing situations, while the BT tool holder is suitable for general processing needs.

Can BT and BBT (BTT) knife handles be shared?

BT and BBT (BTT) knife handles can be shared under certain conditions, but the effects may be different. Details are as follows:

For use on traditional BT spindles:

If you are using a BT toolholder on a conventional BT spindle, this is the normal configuration and will provide performance within design specifications.

If you use a BTT toolbar on a traditional BT spindle, since the BT spindle lacks flange surface contact, the BTT toolholder can only be used like an ordinary BT toolholder, and can only provide taper contact. The result of this is that you cannot take full advantage of the double-contact design of the BTT tool handle, and the rigidity and stability will not be significantly improved.

Use on BTT spindle:

This is the best configuration if you are using a BTT toolholder on a BTT spindle. The double-contact design of the BTT spindle and BBT tool holder can provide the highest rigidity and stability, suitable for high-precision, high-speed machining.

If you use a BT tool holder on a BBT spindle, the BT tool holder can only provide taper contact, and the flange surface will not contact the spindle. In this configuration, you can still process, but you cannot take advantage of the full advantages of the BBT spindle, and the rigidity and stability are not as high as when using a BBT toolholder.

Therefore, BT tool holders and BTT tool holders can be used interchangeably on the corresponding BT or BTT spindle, but the best results require matching tool holders and spindles. For example:

1. The traditional BT spindle uses a BT tool holder. 2. The BTT spindle uses a BTT tool holder.

This maximizes equipment performance and ensures processing accuracy and stability.

To learn more, please go to the official website: Precision tool handle screening BTT series purchase