Customized Hydraulic Expansion Mandrel — High Precision Workholding Solution for Advanced Manufacturing

PARFAITE’s hydraulic expansion mandrel delivers ultra-precise, non-deforming ID clamping with ≤0.003 mm runout, ideal for high-speed, thin-wall machining.

PARFAITE: Precision Clamping Reimagined

I. Precision at the Core: Hydraulic Expansion Mandrel

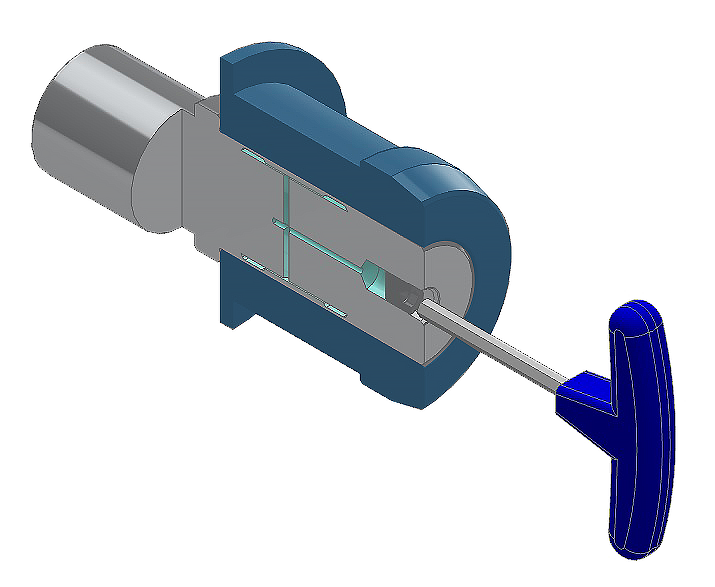

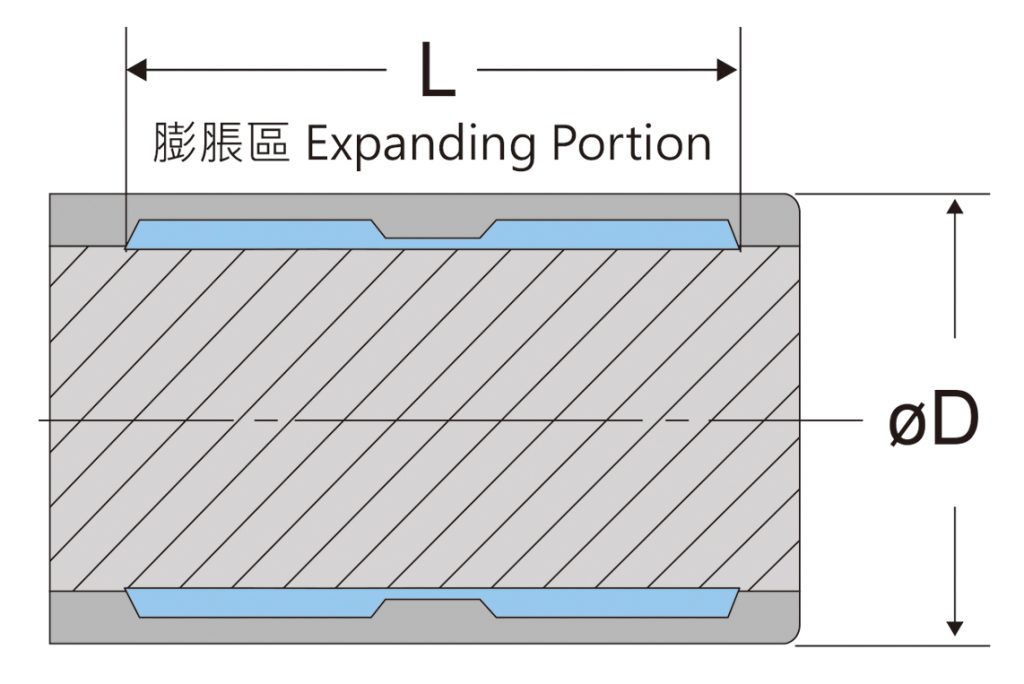

As precision manufacturing advances toward higher speeds, tighter tolerances, and smart automation, the performance of workholding systems directly impacts product quality and production stability. The hydraulic expansion mandrel is engineered to address these demands through high-precision ID clamping, delivering outstanding coaxiality, total runout, and repeatability across a wide range of applications. Unlike conventional three-jaw chucks or tapered mandrels—which may induce deformation or radial runout at high speeds—the hydraulic expansion mandrel applies uniform radial pressure through an internal hydraulic mechanism, forming a high-rigidity interference fit with the workpiece's internal bore. This eliminates surface marring while ensuring stable, high-tolerance engagement.

This clamping solution is widely applied in aerospace, automotive, high-speed spindles, smart machinery, and semiconductor component production, where cylindricity, roundness, and runout control within 0.003 mm are mission-critical.

This clamping solution is widely applied in aerospace, automotive, high-speed spindles, smart machinery, and semiconductor component production, where cylindricity, roundness, and runout control within 0.003 mm are mission-critical.

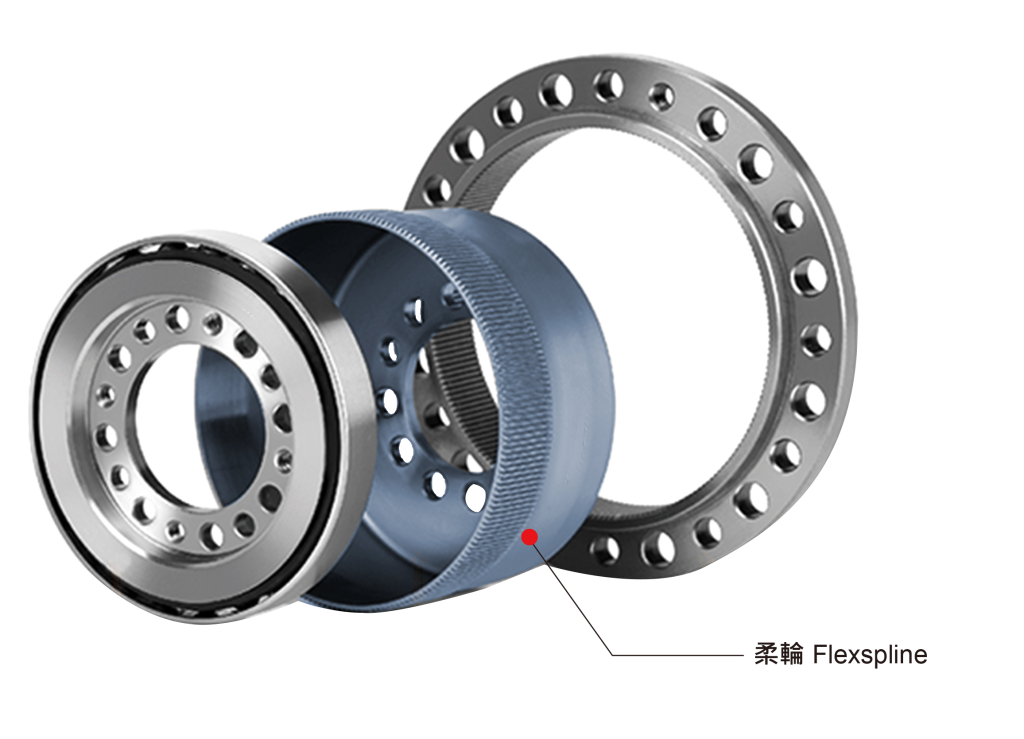

II. Application Highlight: Flexspline Clamping in Harmonic Drive Production

The harmonic drive is a key component in precision robotic systems and micro-motion assemblies, recognized for its backlash-free performance, compact footprint, and thin-walled flexspline geometry. Core components include:

- Flexspline: A deformable, thin-walled cup-shaped gear that enables wave transmission - Circular Spline: A rigid internal gear fixed to the housing - Wave Generator: An elliptical cam that reshapes the flexspline to achieve harmonic motion

Flexspline machining represents a critical challenge due to its geometry. Traditional clamping methods often apply uneven force, resulting in deformation, tooth profile distortion, and concentricity loss. The hydraulic expansion mandrel, however, is applied to support the ID uniformly, maintaining: - Coaxiality and roundness under dynamic wave loading - Total runout within 0.003 mm - No deformation or surface indentation even under high clamping pressure

This solution is actively applied by leading manufacturers in robotic joint production, harmonic reducers, aerospace micro-actuators, and high-precision transmission systems.

III. PARFAITE Case Studies: Multi-Domain Deployment with Proven Precision

As one of the few global suppliers offering full customization of hydraulic expansion mandrels, PARFAITE has successfully supported multiple industries in solving high-difficulty clamping challenges. Our solutions are applied in:

- ID and OD cylindrical grinding of transmission shafts and gears

- Precision honing and finishing for dynamic sealing surfaces

- Grinding wheel and rotor balancing, using high-speed expansion mandrel assemblies

- CNC rotary fixtures requiring high concentricity under automated cycles Clamping capabilities span from ø4 × L8 mm for micro-flexspline clamping to ø113.15 × L28 mm for heavy-duty OD grinding. This range showcases the system’s application flexibility and scalability.

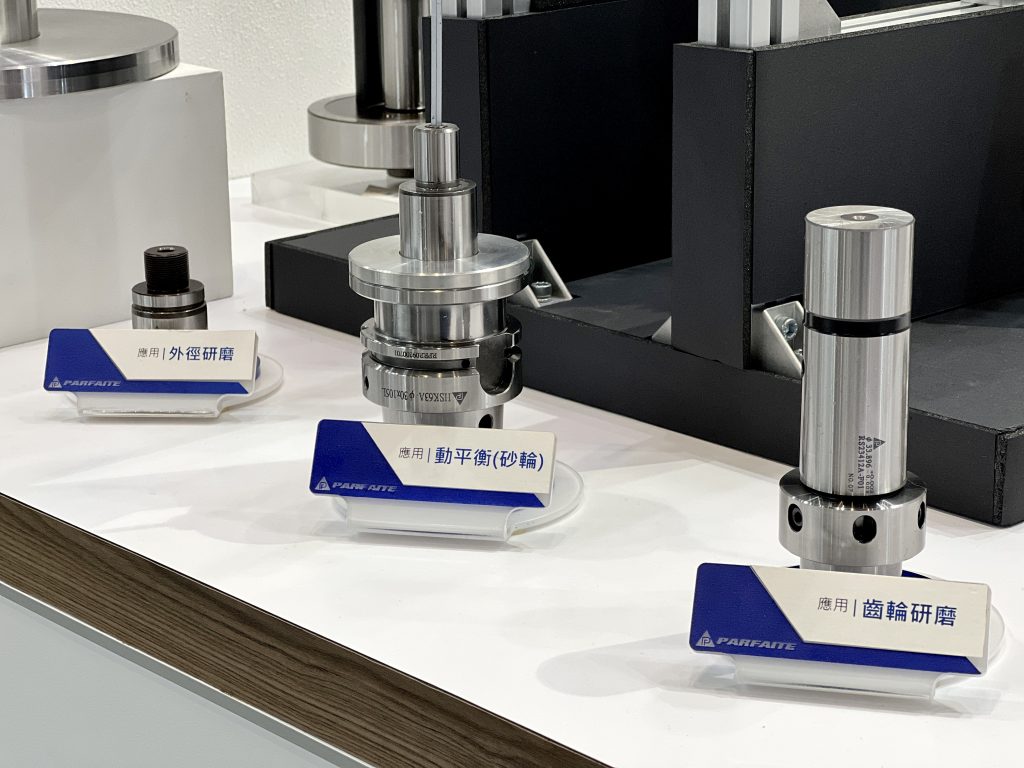

Application Examples of Hydraulic Expansion Mandrels

Application Examples of Hydraulic Expansion Mandrels

Key Technical Advantages (GD&T-Aligned)

- Total runout control ≤ 0.003 mm, ensuring rotational symmetry

- Applied in high-speed operation

- Quick-change design reduces cycle time and improves operational uptime

- Non-deforming, uniform pressure preserves thin-wall and surface integrity

- Modular and customizable for CNC integration and automatic tool changers

These advantages have been applied to enhance throughput, improve tool longevity, and reduce scrap rates across precision production lines.

IV. PARFAITE’s Design Capability and Market Competitiveness: From Taiwan to the Global Stage

PARFAITE specializes in the design, manufacturing, and sales of built-in motor spindles, precision tool holders, and custom cutting tools, making it one of the few manufacturers worldwide capable of producing all three categories at high standards. With over 40 years of mature and proven technical expertise, PARFAITE not only masters critical manufacturing processes but also emphasizes modular design, customization, and production line integration. Whether the project involves standard configurations, special applications, or complex systems requiring automated tool change, our engineering team can perform reverse design and simulation analysis based on: - Workpiece geometry and material - Spindle interface and machining dynamics - Balancing and vibration requirements - Targeted GD&T parameters (e.g., total runout, cylindricity, coaxiality)

As Taiwan’s precision components industry continues expanding in international markets, high-end hydraulic expansion mandrels are becoming key enablers for quality enhancement, brand reputation, and customer confidence. PARFAITE remains committed to the mission of "clamping with greater precision and manufacturing with higher reliability", offering tailor-made mandrel solutions to help manufacturers achieve more stable, efficient, and scalable machining outcomes, and working closely with global clients in the transition toward smart manufacturing.