Diversity of ER Tool Holders (ER Tool Holders) - Clamping

Introduction to ER knife handle

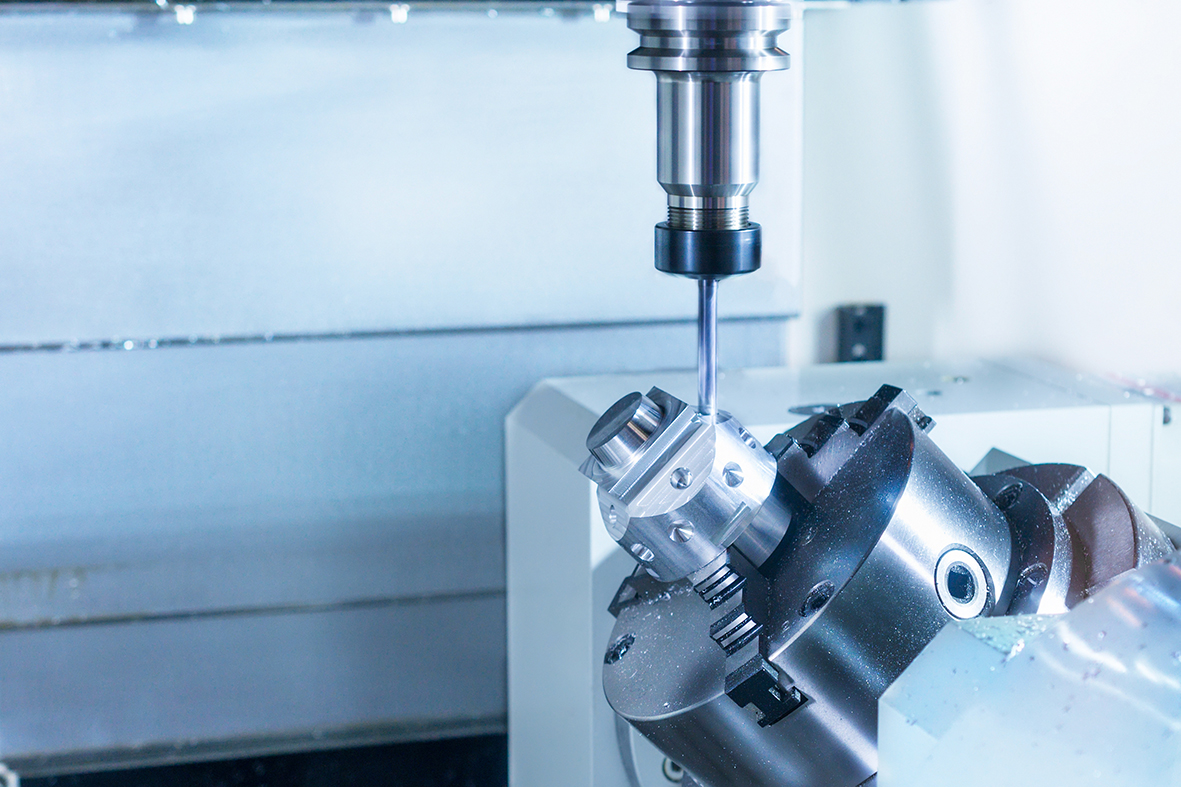

ER tool holder (ER tool holder) is a tool clamping system widely used in CNC machine tools. It is mainly responsible for clamping various tools such as drill bits, milling cutters, and screw taps. Its design relies on the clamping principle to rely on the action of the nut. When the nut is tightened, uniform pressure will be exerted on the collet, making its inner hole closely fit the shank of the tool, thereby achieving firm clamping. High versatility and wide versatility cover almost all common processing needs. Therefore, it is widely used in the general machining industry, and becoming the first choice for general-purpose fixtures is also the main core value of this product. This article will briefly discuss the composition, characteristics, application scope and advantages of ER tool holders, so that users can better understand ER tool holders.

The composition and characteristics of ER tool handle

ER tool holder consists of the following main parts:

1. ER elastic collet

The ER elastic collet is the core component of the ER tool handle. It is usually made of high-quality spring steel or stainless steel and has extremely high hardness and wear resistance. Its elastic design allows the collet to adapt to tools of different diameters within a certain range, thereby improving clamping flexibility. In addition, ensuring excellent surface roughness of the collet can ensure accuracy and stability during the clamping process.

2. Selection of nuts

Different nuts can be selected for ER tool holders according to different processing conditions. Matching different nuts can help improve processing accuracy. For example, steel ball nuts can help improve clamping force and accuracy and are suitable for high-precision processing. The use of high-speed steel ball nuts improves accuracy and is more suitable for high-speed processing.

3. Clamping mechanism

The clamping principle of the ER tool holder relies on the function of the nut. When the nut is tightened, it applies even pressure to the collet, causing its inner bore to fit tightly against the shank of the tool, resulting in a secure clamping. This design provides high clamping force and stability, maintaining accuracy even in high-speed machining environments.

Application scope of ER tool holder

ER tool holders are widely used in various mechanical equipment such as CNC comprehensive machining centers, lathes, milling machines, and drilling machines, and are responsible for achieving firm clamping and stable operation of tools.

Precision machining

In the CNC machining environment of high-speed and precision cutting, the ER tool holder has become a key component in the machining process due to its high precision and high rigidity. It can ensure that the tool does not shift or vibrate at high speeds, thereby improving the surface quality and dimensional accuracy of the workpiece.

Automated production

With the improvement of industrial automation, ER tool holders are widely used in automated production lines, playing an important role in rapid tool change and accurate positioning. Its design simplifies the operation process, shortens downtime, and greatly improves production efficiency.

General machining

Due to its versatility, the ER tool holder is suitable for holding drills, screw taps, milling cutters and other tools, covering almost all common processing needs. Therefore, it is widely used in the general machining industry and has become the first choice for general-purpose fixtures.

Advantages of ER tool holder

1. Good accuracy

The design and manufacturing of ER tool holders are precisely calibrated, and the concentricity during the clamping process is extremely high, ensuring the stability of the tool during processing. This high-precision feature is essential for machining that requires high-quality surface finishes and tight dimensional tolerances.

2. High rigidity

The elastic collet of the ER tool handle provides strong clamping force during the clamping process, which can effectively suppress tool vibration and ensure stability. At the same time, it can also withstand the centrifugal force generated during high-speed operation and is suitable for processing various complex workpieces.

3. Versatility

The specifications of ER tool holders cover a wide range, including ER8, ER11, ER16, ER20, ER25, ER32, ER40, etc. Different specifications correspond to different size tool clamping requirements. This variety of specifications enables ER toolholders to adapt to various processing scenarios, from small parts processing to large workpiece manufacturing.

ER tool holders are suitable for a variety of tool specifications and processing scenarios, whether drilling, milling or tapping operations, they can be easily handled. Its elastic expansion and contraction function further enhances its adaptability and reduces the frequency and cost of tool replacement.

4. Easy to operate

The operation of the ER tool handle is simple and fast, and the installation and removal process of the tool is very intuitive. The cooperative design of the nut and collet allows the operator to easily complete the tool changing task, greatly shortening production time and improving production efficiency.

Purchase and maintenance of ER tool handles

About the selected recommendations

Specification matching: According to the diameter of the tool required to be clamped, select the appropriate ER collet and tool holder specifications.

Accuracy requirements: For high-precision machining requirements, it is recommended to choose high-quality, precision-calibrated ER tool holders.

Material selection: The ER knife handle made of high-quality materials can provide longer service life and stable performance.

Maintenance recommendations

Cleaning: Before each use, use a hand-held air gun to thoroughly clean the ER tool handle to ensure that there are no foreign objects inside the collet to avoid affecting the clamping effect.

Lubrication: Lubricate and maintain the nut and knife handle regularly to prevent rust or jamming.

Inspection: Regularly check the collet and tool handle for wear or damage, and replace them if necessary.

As an important connection device between machine tools and cutting tools, ER toolholders have become an indispensable fixture system in modern manufacturing due to their versatility. In the future, with the continuous innovation of technology, ER tool holders will play a greater role in the field of intelligent and efficient processing, providing strong support for the progress of the manufacturing industry.

understand moreER knife handle