HER Collet Chuck Toolholders Deliver High Precision and Reliable Machining Through Structural Stability

As CNC milling continues to pursue higher efficiency, more consistent quality, and extended continuous operation, machining conditions have become increasingly complex and demanding. Higher spindle speeds, heavier feed rates, and long-duration high-load cutting all place significantly greater forces and vibration on cutting tools and toolholders. In this environment, the true determinant of long-term machining stability is not only the cutting tool itself, but also the structural stability of the toolholder—an element that is often underestimated.

HER collet chuck toolholders are developed with structural stability as their core design philosophy. Rather than merely reinforcing individual components of conventional ER toolholders, HER rethinks the entire structural logic from the perspective of load distribution, clamping stability, and long-term reliability. This holistic optimization allows the toolholder to maintain stable clamping under high load and high-speed machining conditions, naturally achieving precision performance at the 5 µm level in real-world applications.

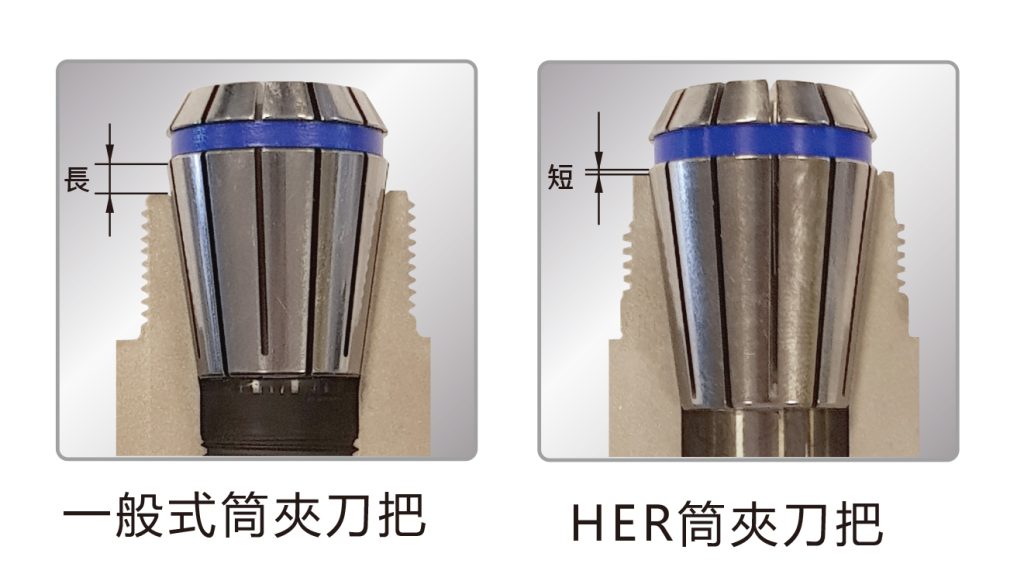

Deep-Seated Collet Structure for More Even and Stable Load Distribution

One of the most distinctive features of HER collet chuck toolholders is the deep-seated collet design, where the collet is fully embedded into the toolholder body, creating an extended contact length and large support area. This structural configuration prevents cutting forces from concentrating at a single point and instead distributes loads evenly along the contact surfaces between the collet and the toolholder, significantly enhancing overall load-bearing capability.

As machining intensity increases and cutting forces rise, the deep-seated collet structure effectively suppresses outward expansion and elastic deformation of the collet. This ensures a consistently stable clamping condition over extended machining cycles. For the shop floor, this means reduced micro-movement of the tool during long operations and a consistently stable structural state—making high-quality machining results predictable and repeatable, rather than dependent on short-lived ideal conditions.

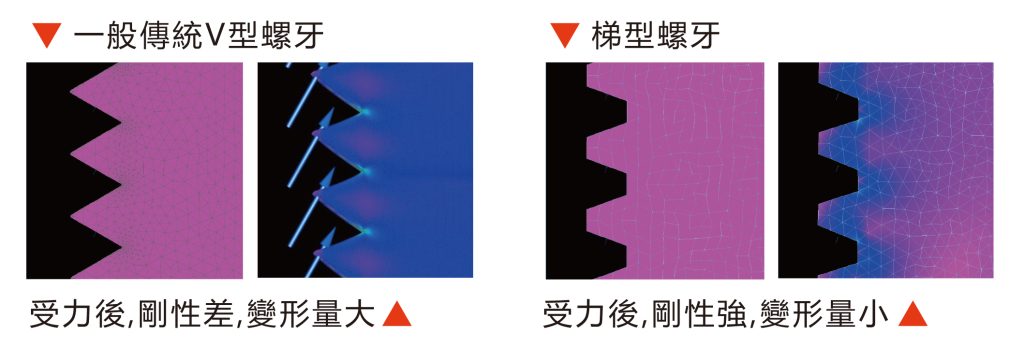

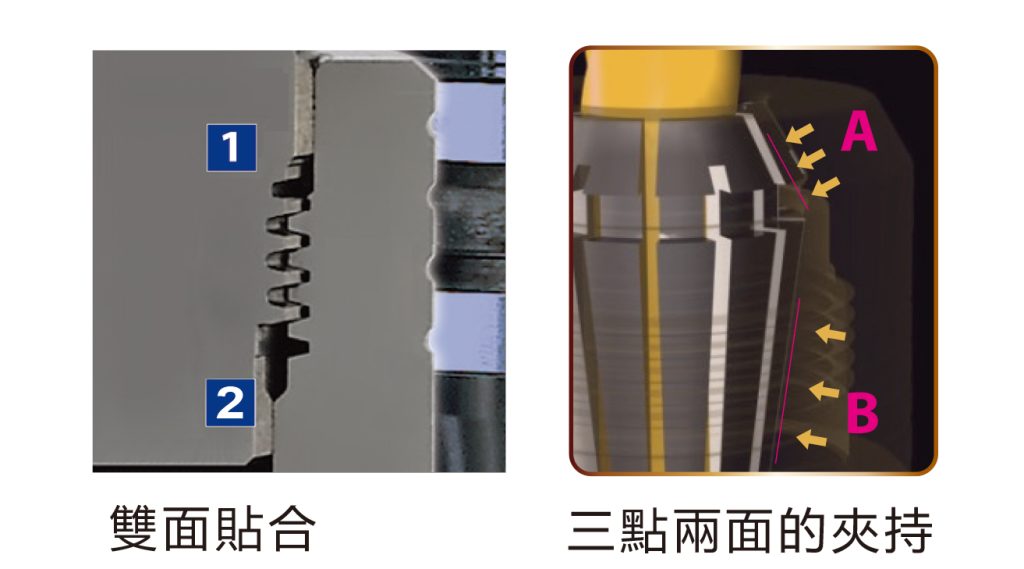

Trapezoidal Threads and Guided Tightening for Long-Term Clamping Stability

HER collet chuck toolholders utilize trapezoidal threads not simply to increase tightening torque, but to ensure that clamping force is transmitted steadily and efficiently to the collet itself. Compared to standard thread forms, trapezoidal threads offer superior load angles and higher load capacity, significantly reducing thread wear and structural fatigue under repeated tightening and prolonged use.

Combined with a guided tightening mechanism, the nut maintains stable axial movement during tightening, preventing misalignment and localized stress concentration. This design ensures that clamping force remains consistent during long machining cycles and does not deteriorate due to continuous operation, further reinforcing overall machining stability.

One-Piece Full-Circle Nut Enhancing Rotational Stability and Structural Safety

In any rotating machining system, the nut is an integral part of the rotating structure, and its design directly affects overall stability and operational safety. HER collet chuck toolholders feature a one-piece, full-circle nut design that ensures symmetrical mass distribution, helping to reduce imbalance and vibration during high-speed rotation.

Compared to conventional ball-bearing nuts, the one-piece construction eliminates gaps, wear points, and localized fatigue caused by long-term use, while also reducing the risk of chip ingress. This design allows the toolholder to maintain structural integrity during prolonged operation, further enhancing the reliability and safety of the entire machining system.

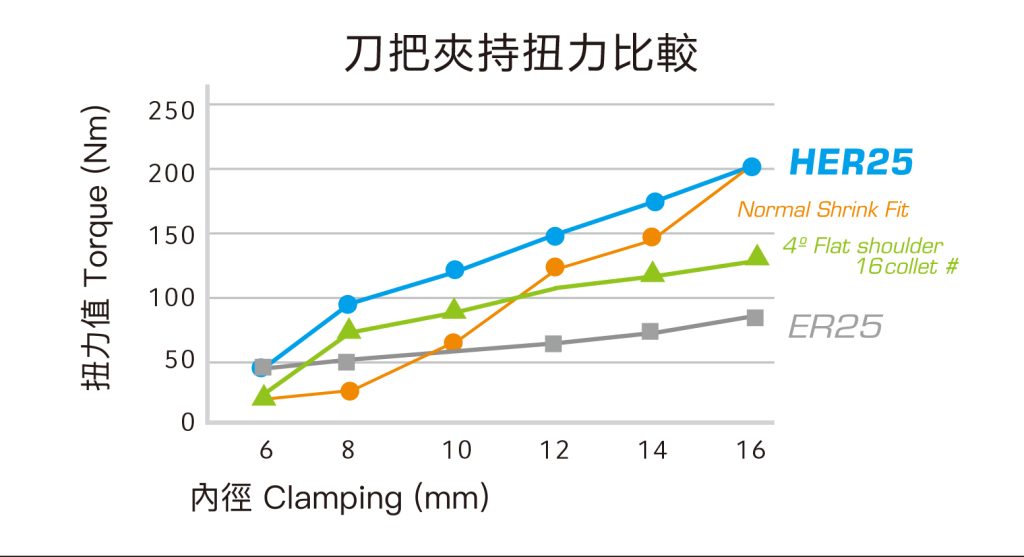

High Clamping Force as a Natural Result of Overall Structural Rigidity

The high clamping force achieved by HER collet chuck toolholders is not the result of strengthening a single component, but rather the cumulative outcome of a comprehensively rigid structural design. Through deep-seated collet support, trapezoidal thread force transmission, and optimized load distribution, HER toolholders maintain stable clamping under high-load machining conditions without clamping force degradation caused by vibration or centrifugal effects.

This structural performance allows machinists to confidently apply higher feed rates and cutting loads while maintaining machining quality and stability. Ultimately, this translates into consistent and repeatable precision at the 5 µm level—precision that exists on the shop floor, not just in inspection reports.

Practical Value for a Wide Range of Precision Machining Applications

HER collet chuck toolholders are ideally suited for mold and die machining, precision component manufacturing, automotive and motorcycle parts, and other high value-added machining applications. In these fields, toolholders must withstand continuous cutting and repeated loading over long periods, where any structural instability can directly impact machining quality and machine tool lifespan.

For confined or interference-prone machining environments, the THER slim-type collet chuck toolholder serves as the optimal alternative within the HER series. While fully inheriting the superior clamping structure of the HER design, the reduced outer diameter of the slim-type configuration allows effective cutting performance in tight and demanding machining conditions, completing the HER toolholder lineup.

With a structure-driven design philosophy at its core, the HER series is engineered not just for short-term performance, but for long-term, consistent support—ensuring stable, high-quality, and highly repeatable machining results on the production floor.