July 11, 2025

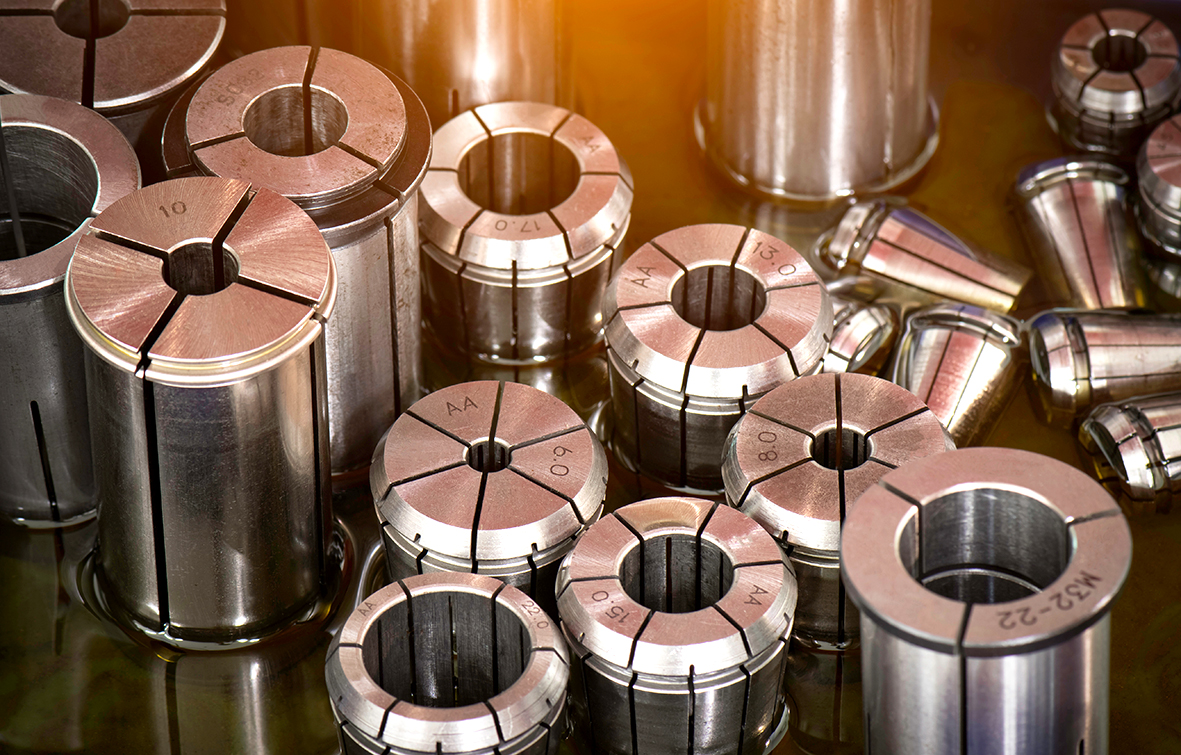

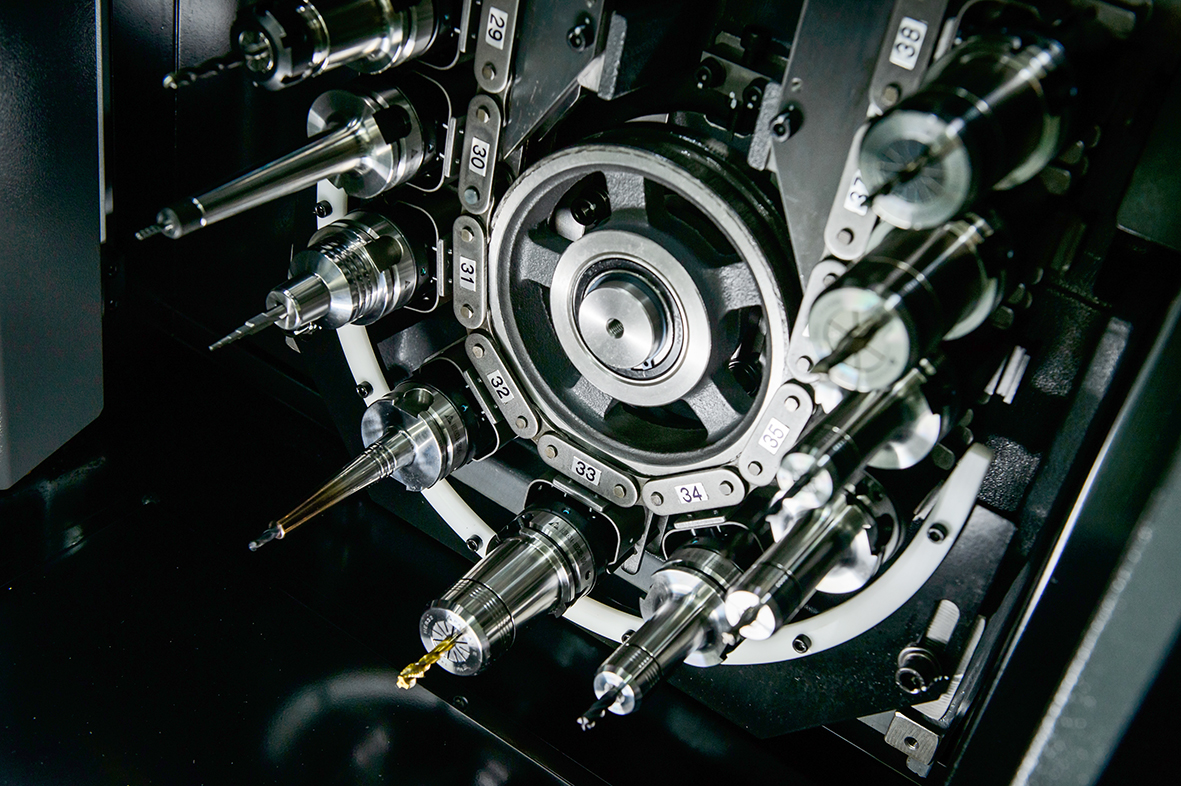

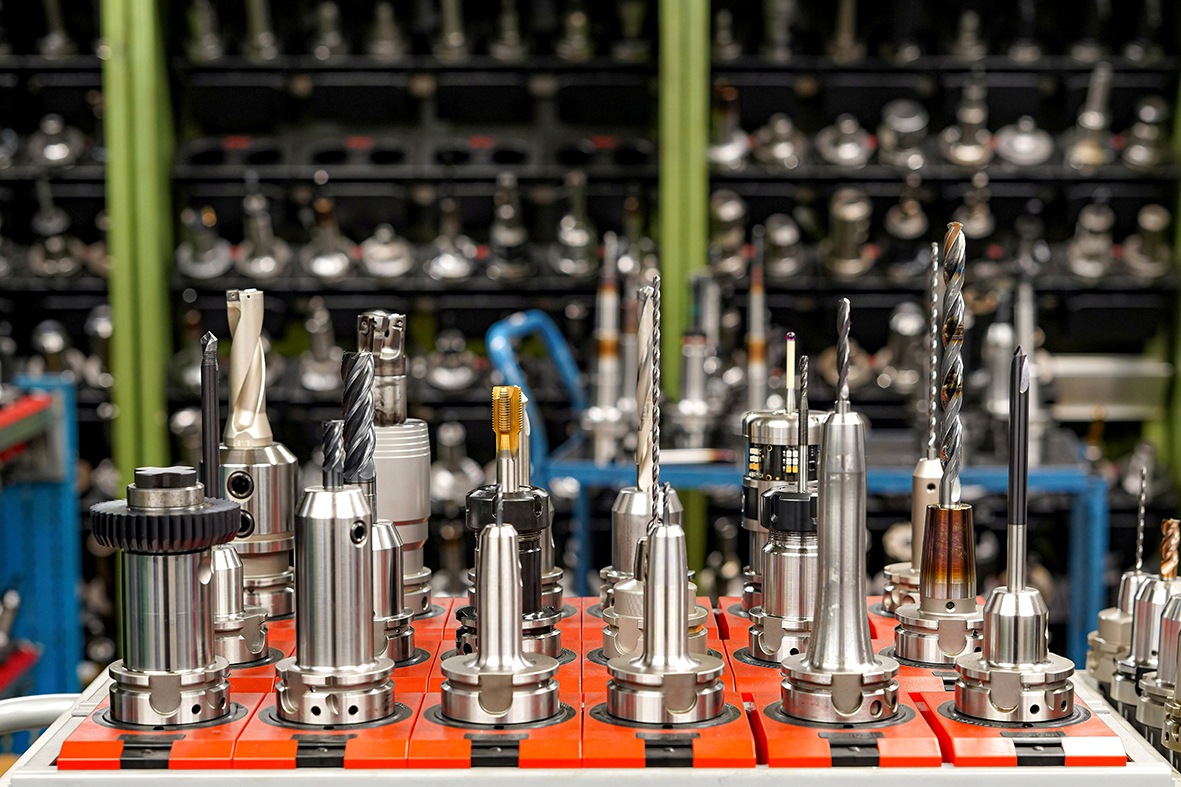

In the ever-evolving world of CNC machining, precision, efficiency, and stability are the three pillars every metalworking professional strives to achieve. While the tool holder is often the focal point of most tooling systems, there's one crucial component that frequently goes unnoticed — the collet. Acting as the vital link between the cutting tool and the holder, a collet’s gripping performance directly impacts machining accuracy, tool life, and overall machine stability. In this article, we’ll explore the functions, types, and maintenance tips for collets, helping you build a more competitive CNC machining solution.