Heat & Special Treatments

HEAT & SPECIAL TREATMENTS

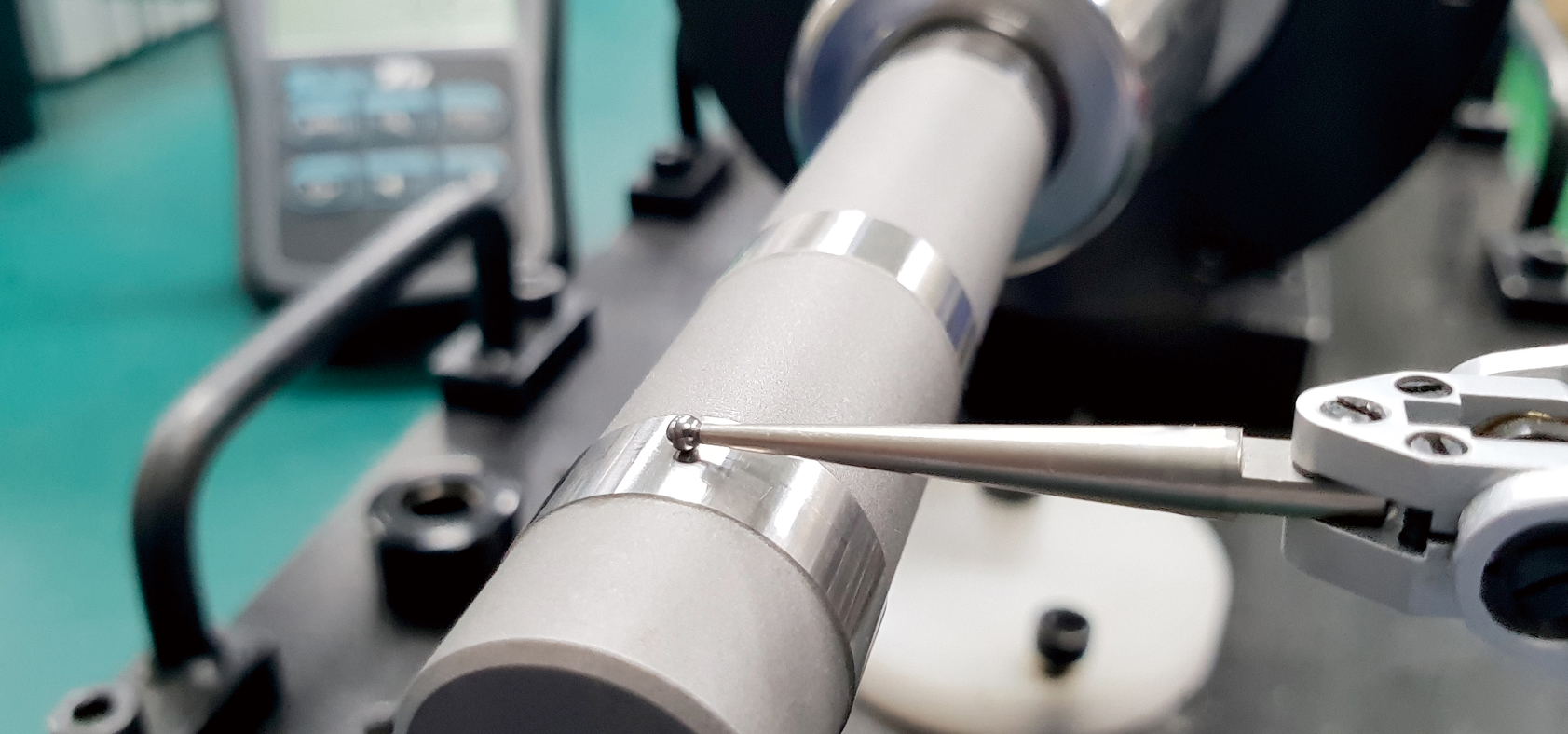

Lack of proper heat treatment, a tool holder with high accuracy and long handle life can not be achieved even with advanced material and processing equipment. Correct and excellent heat treatment can heatmaterials meanwhile with q uencher procedure to obtain high rato of martensite. The product will have excellent mechanical properties in terms of hardness, density , wearability, bending strength, tensile stress. On the other hand the wrong or poor heat treatment causes the material of low density, inhomogeneity of hardness, too large residual stress, too much austenitizing remained, grain size and density abnormal, which resulting in failure of achievement of desired mechanical properties as well as material deformation or cracks, thereby, affecting the accuracy and tool life that is the most important part of the tool holder.

Although PARFAITE has sub-contractor for the procedure of heat treatment. The qualified manufactures is selected by strict quality guidelines regardless the cost. Only the best manufacture can get this opportunity to cooperate with us in long term and discuss with Japanese consultant to improve quality from time to time. PARFAITE believes that only work step by step, and no jerry building is accepted to produce tool holders of accuracy and long life.

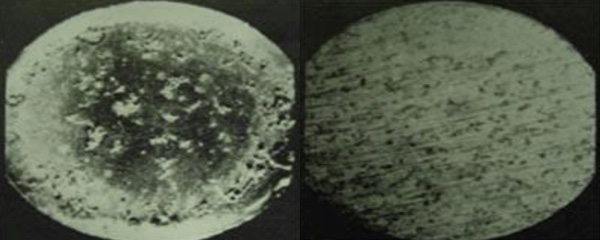

In addition, as the picture showed below, during the process of quenching not only martensite is produced but also austenite retained. Austenite is not a stable internal structure influenced by external factors in terms of temperature, processing which provide energy to turn austenite to martensite and causing volume expansion then changing the dimensions. After the quenching procedure, the percentage of retained austenite is about 2% to 30%. The least percentage is 0.15% and the most is 30% according to the type of steel and quenching procedure. The internal structure of retained austenite is a unstable phase which means the more austenite the less hardness is. Austenite will be changed by temperature and if the phase is changed the size is changed as well. Therefore, to reduce austenite is very important, but during cooling procedure of quenching, austenite will not be stable. The goals of to increase martensite producing, to enhance quenching and to reduce deformation of quenching are not easy to achieve.

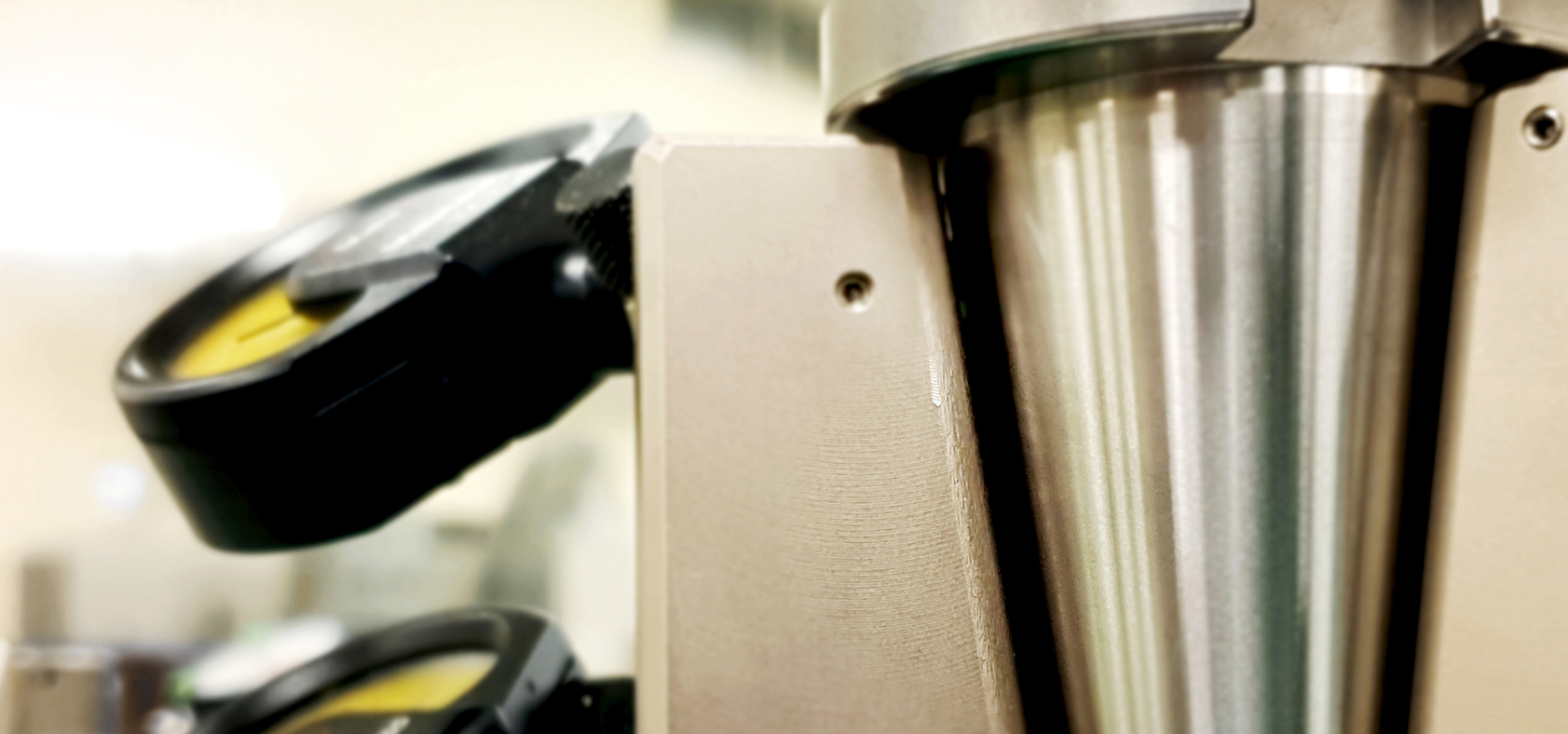

The unstable condition of material will make changes of accuracy of taper, etc. due to the shortages of heat treatment processing, the serious consequences will state in the section of accuracy of handle. As a result, the quality of ultra-precision tool holders in hydraulic and HSK full range are perfect. There are the most advanced technology and special treatment used in preventing tool holders deformation, increasing the wear resistance, hardness, homogenized hardness, improving mechanical properties and adjusting expansion in the matches parts. PARFAITE abandoned material of Cr-Mo alloy (which meets the standard of HSK DIN69893) for hydraulic or HSK tool handles on high precision requirement. The using of high grade material will extent the tool life and accuracy of those expensive tools for customers without any worries.

The picture of internal structure before special treatment ( retained austine's unstable structure) The picture of internal structure after special treatment (retained austenite turn into martensite)