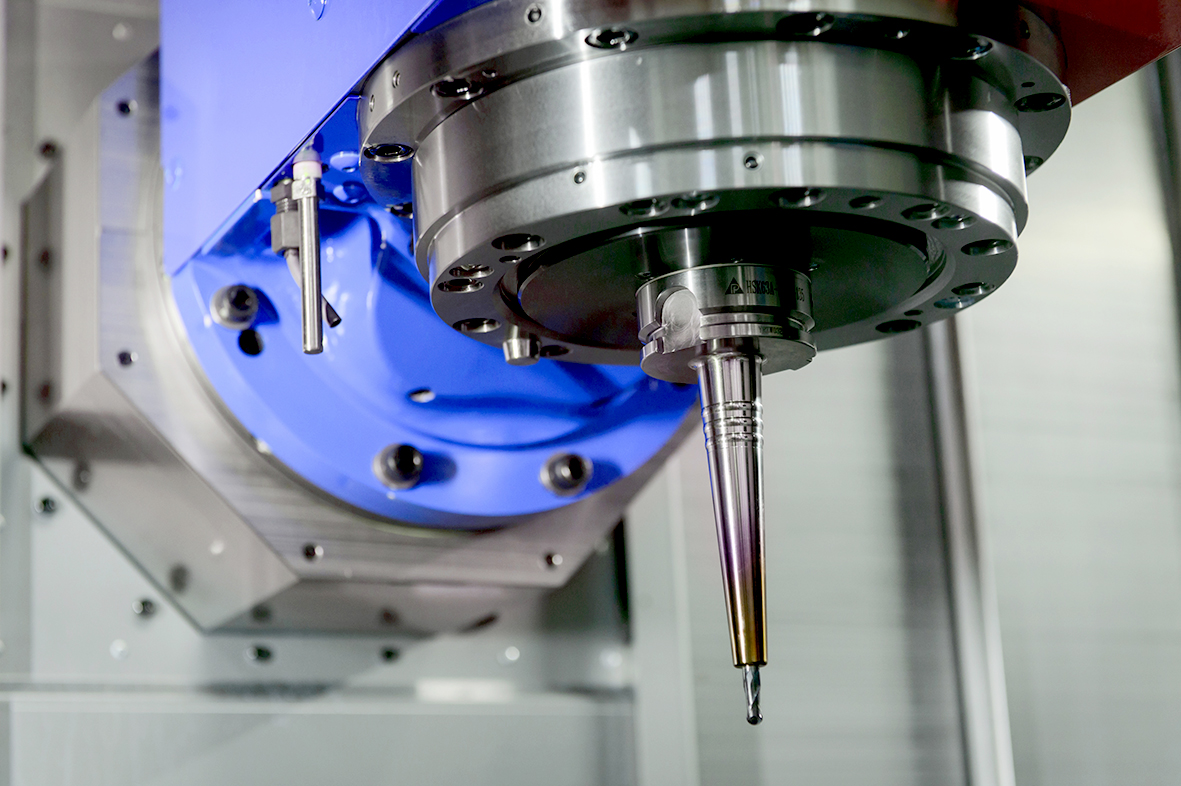

Introduction to Heat Shrink Tool Holder (Sintered Tool Holder) - Clamping

Heat shrink tool holder, also known as sintered tool holder, has been widely used in the industry as an efficient and stable tool clamping solution. In the field of modern precision machining and high-speed machining, stability and accuracy of heat-shrinkable tool holders play a key role in production efficiency and product quality. Here, the basic principles, characteristics, advantages of heat shrink tool holders, comparison with traditional chuck-type tool holders, and maintenance and maintenance recommendations will be introduced to let users understand this technology.

Basic principles of heat shrink tool handle

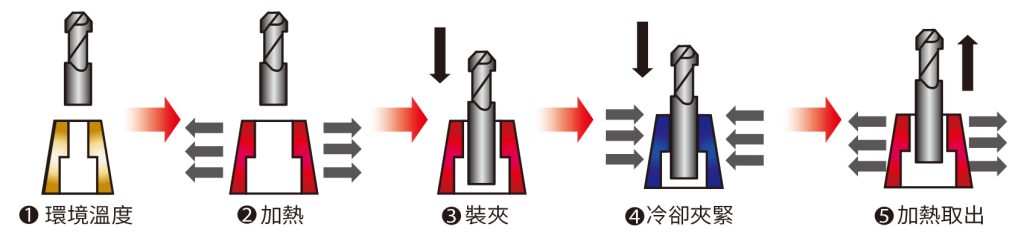

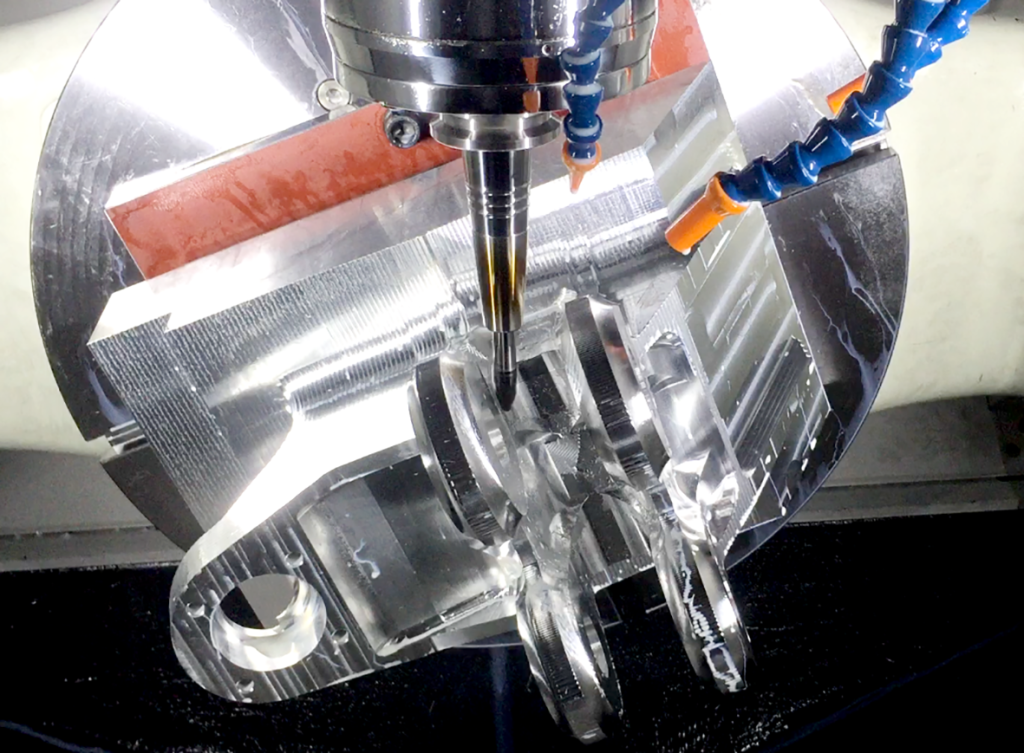

The heat shrink tool handle is a clamping component that connects the tool handle and the tool. There are no parts between the tool and the heat shrink tool handle. When clamping the tool, use a thermal induction device (i.e. heating machine) to heat the clamping part of the heat shrink tool holder to 250°C~425°C in a short time. When its inner diameter expands to the diameter of the clamping part of the tool, quickly The tool is loaded into the heat-shrink tool handle. When the heat-shrink tool handle cools and shrinks, the tool and the heat-shrink tool handle form an interference fit, thereby achieving reliable, high-precision and effective clamping of the tool by the tool handle.

Compared with the elastic chuck, the heat shrinkable tool handle is composed of a single piece of the tool handle, there is no cumulative accuracy error caused by the combination of parts, and it relies on the shrinkage of the metal to clamp the tool. This mechanical shrinkage method has small dispersion and stable accuracy. high. In addition, heat-shrinkable tool holders have higher clamping torque, and have better rigidity and dynamic balance when processing in high-temperature areas.

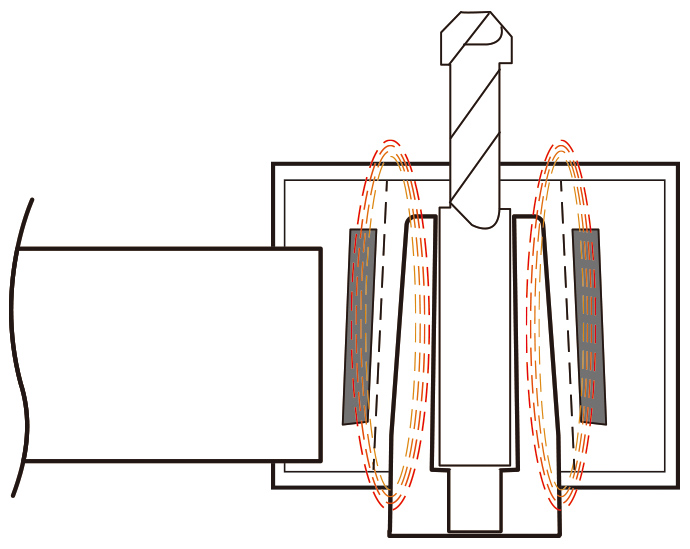

The eddy current generated by the induction coil generates atomic oscillation and friction to generate heat energy, which is heated from the inside of the tool holder to the outside of the tool holder. After the thermal expansion, the tool is installed into the tool holder, and is cooled and clamped to complete the tool holder installation. folder.

Characteristics of heat shrinkable knife handles

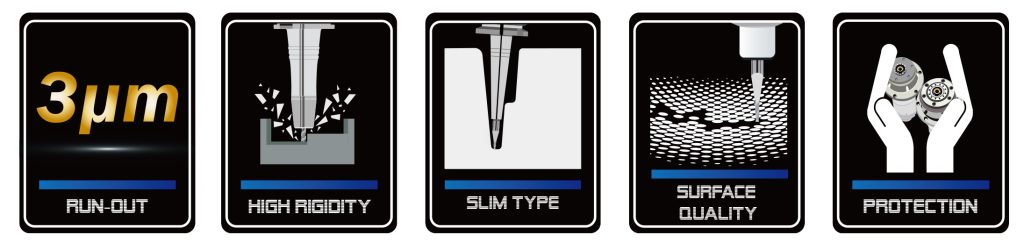

1. There are two types of heat-shrinkable tool handles to choose from: CR standard heat-shrinkable tool handle, which has a good one-piece steel shape and can be finished or roughed; SR slender heat-shrinkable tool handle can also avoid drying and involve narrow edges. Advantages of Angular Space Effect

2. The heat-shrinkable tool holder has good concentricity and the deflection accuracy can usually reach 3 μm or higher. It is suitable for processing scenarios that require high precision, improves the surface finish of the processing, and reduces tool wear.

3. The structure is simple with less vibration, and the tool arbor and the tool are closely matched. You only need to select the appropriate heating machine, heating and cooling tool clamping parameters to directly clamp tools of various specifications.

4. The tool is fully clamped at 360°, and the rigidity is greatly improved. It is suitable for high-speed rotation applications and is often used in industries that require high-speed cutting, such as aviation and precision molds.

5. High clamping force and good stability. The tool holder expands after heating, is inserted into the tool handle, and shrinks after cooling to firmly clamp the tool, achieving high stability and clamping force, and effectively preventing the tool from loosening during processing. , improve processing safety.

6. Simple and efficient, long life. Made of high-quality materials, precision machining and heat treatment, as long as the correct heating parameters are followed, the accuracy will not change for more than a thousand times of thermal loading and unloading. The performance is stable, durable, reliable and has a long service life.

Advantages of heat shrinkable tool handles

Compared with traditional chuck-type tool holders, heat-shrinkable tool holders have many technical advantages. First of all, its clamping force is extremely stable and uniform, which can effectively reduce tool vibration, thereby improving machined surface quality and extending tool life. Secondly, the heat-shrinkable tool handle has a simple structural design and does not require additional mechanical clamping devices, reducing maintenance requirements.

In addition, the high concentricity of the heat-shrinkable tool holder helps improve machining accuracy, especially in high-speed machining, which can effectively reduce deflection errors. Because the heat-shrinkable tool holder can be adapted to a variety of tool specifications, the operational flexibility is greatly improved, and its service life is usually long. It is a cost-effective option for factories that need to frequently replace tools.

In terms of cost-effectiveness, although the initial purchase cost of heat shrink toolholders is higher, the long-term use cost is more competitive due to its durability and reduced downtime.

Maintenance and maintenance of heat shrink knife handle

Correct care and maintenance are the key to extending the service life of heat shrink tool handles. First of all, the heating and cooling specifications provided by the manufacturer should be strictly followed during operation to avoid material fatigue caused by overheating or cooling too quickly. Secondly, the tool handle should be cleaned regularly to ensure that there is no oil or metal shavings on the internal surface that interfere with tool clamping.

In addition, operators need to regularly check the appearance and function of the tool handle and replace it promptly if wear or cracks are found. When storing knife handles, avoid humid conditions to prevent metal oxidation. Adopting appropriate maintenance methods can effectively extend the service life of the knife handle and maintain its stable performance.

As an important component in modern processing technology, heat shrinkable tool holders have become an ideal choice for precision and high-speed processing due to their high precision, high stability and durability. By understanding its principles, characteristics, advantages and maintenance methods, and choosing appropriate products based on processing needs, production efficiency and processing quality can be effectively improved. With the further development of technology, heat shrink tool holders will play an important role in more application fields.