December 9, 2025

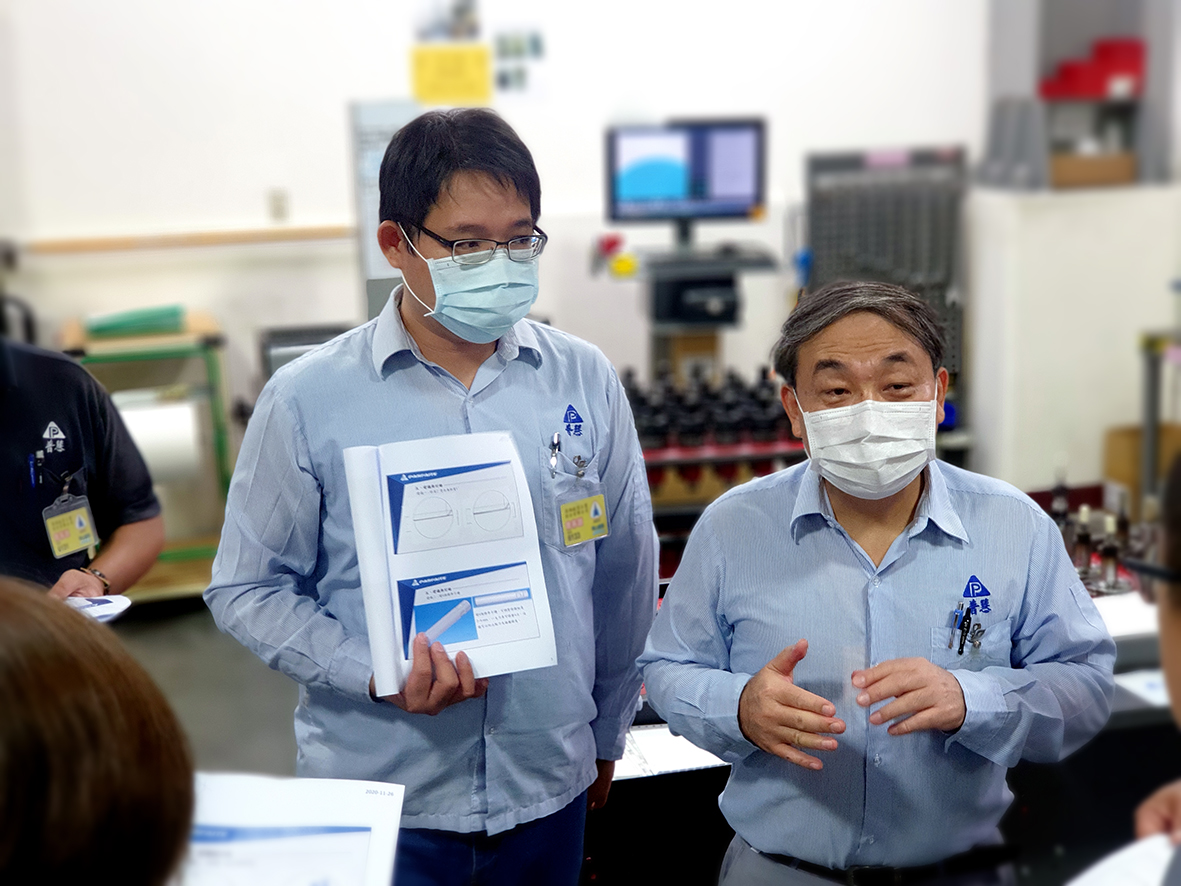

Parfaite has always been committed to helping customers use every product correctly and efficiently. This commitment is not only a key reason we continue to earn our customers’ trust, but also enables us to stay closely connected to real machining environments and understand the challenges operators face on the shop floor.