What is a CNC tool holder ? Understand 3 selection criteria and 3 key technical points

About the CNC Tool handle and what role does it play in CNC machine tools?

With the demand for machining accuracy and automation, CNC machine tools have been widely used in factories. These machine tools and the tools used come from different places and have different models and standards. This article will give a brief introduction to the field of tool holder , one of the important accessories required in CNC machine tool processing.

3 Standards for Selecting CNC Tool Holder

CNC tool holder orTool holderThe CNC Tool Holder is a "bridge" connecting the machine tool spindle and the cutting tool, and is responsible for the important function of connecting the upper and lower. The upper part mainly reflects that some parameters such as the performance, torque, and speed of the spindle are output through the tool holder; the lower part reflects the The tool holder needs to be clamped to achieve normal processing, which is related to the processing accuracy, tool life, and processing efficiency, and affects the final processing quality and processing cost. Therefore, matching the applicability of the knife handle under different processing conditions can give full play to the benefits of getting twice the result with half the effort. Therefore, it is very important to choose a suitable knife handle correctly. Since the requirements of various processing are not the same, the tool holders with different clamping methods are corresponding to it. Here, we briefly introduce the general characteristics of various knife handles as follows.

To choose a Tool handle correctly, you must first understand its classification method, and there are three ways to distinguish it.1. The specifications of the handle 2. The system of the clamping end 3. The consideration of machining accuracy and function

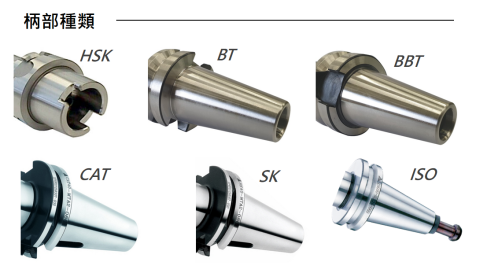

1. Distinguish according to the specifications of the handle; that is, the system in which the spindle of the machine and the handle of the tool handle can be combined.

The shank system is also divided into two categories according to the taper of the spindle hole of the machining center

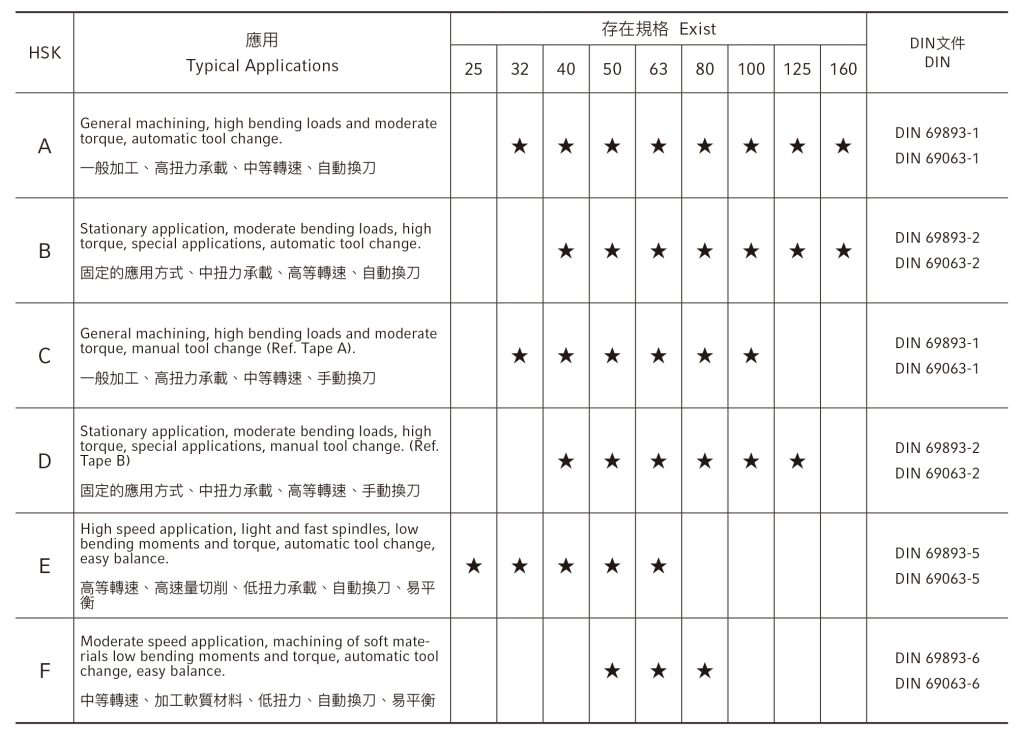

HSK vacuum tool holder with a taper of 1:10

● HSK specification (DIN69893) has A, B, C, D, E, F but the commonly used specification is

HSK-A (with keyway) and HSK-E (without keyway)

Another: SK universal handle with a taper of 7:24

● BT specification (JISB6339) has two faces supporting BTT system

● SK specification (DIN69871)

● CAT specification (ASME B5.50)

● ISO specification

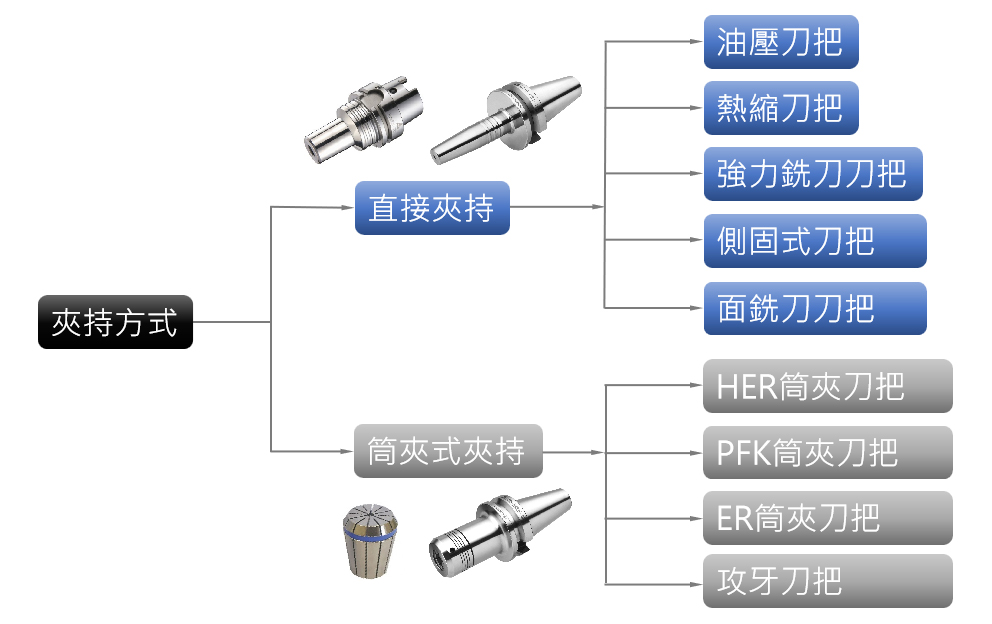

2. Distinguish according to the clamping end system; that is, the way the handle clamps the tool.

The clamping method is divided into two categories: direct clamping and collet clamping.

Directly clamped are:

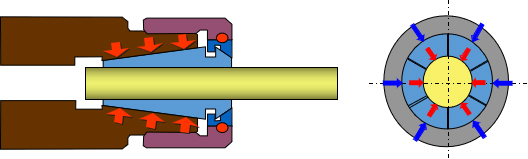

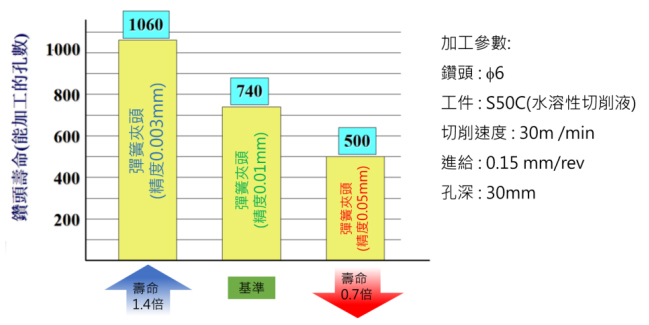

● Hydraulic ChuckAlso known as hydraulic tool handleThe locking method of hydraulic expansion technology is adopted to quickly change the tool, and meet the high-precision requirements of yaw accuracy ≦ 0.003mm, and reduce cutting chatter to improve production efficiency by virtue of damping and vibration reduction performance.

● Heat shrinkable knife handle also known asSintered tool holderThe heat-shrinkable clamping structure is adopted, and the inner hole is expanded by induction heating to clamp the tool, and then cooled to achieve the clamping effect.

● Power Milling Chuck SetYaw accuracy≦0.01mm, special needle roller design, reduce frictional resistance during locking, super strong clamping force, can avoid tool drop during heavy cutting.

● Side-fixed milling cutter holderSide locking tool handle, super clamping force, suitable for all kinds of heavy cutting.

● Face Mill ArborSpecial tool holder for face milling cutterhead, suitable for face milling.

Collet clamping (consisting of nut + collet + Tool handle body) are:

● HER collet ChuckThe trapezoidal thread and the unique structural design make the collet produce high rigidity and super strong clamping torque when clamping the tool, and it is highly versatile with the universal ER collet.

● PFK Collet ChuckThe collet is designed with a unilateral 4° angle and improves the gripping force of the knife handle.

● ER collet ChuckCombined with ER collets, it has high versatility and can be used for various processing.

● Tap adapter?The handle is specially designed for tapping, with different collets, you can choose rigid tapping or safe torque tapping.

3. Distinguish according to processing accuracy and function;Due to the different processing procedures and the selection of tool size, the selection of tool handles for heavy cutting or finishing is different. In addition, milling, face milling, drilling, reaming, boring, tapping, and even small diameter interference and edge cleaning The functions of corner trimming are different, so it is necessary to choose the corresponding function of the knife handle to complete

Discuss 3 key factors affecting the accuracy of Tool handles?

1.TAPER ACCURACYpart:

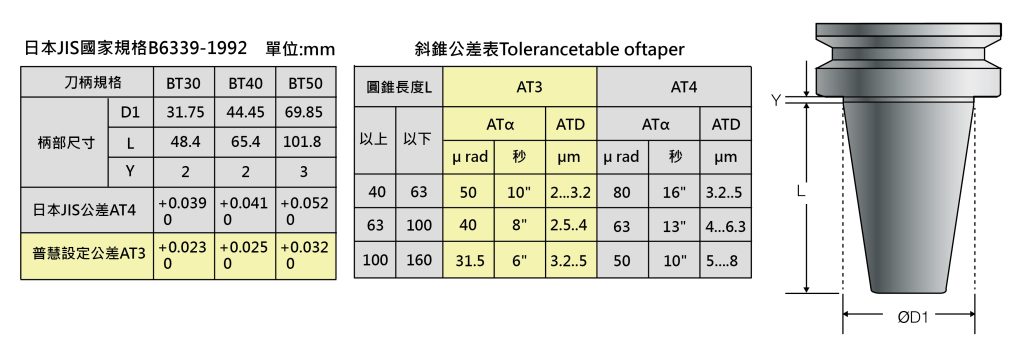

Shank accuracy refers to the tightness tolerance between the handle of the tool handle and the inner hole of the spindle. This tolerance level is divided into 9 levels from AT 1 to AT9 (JIS 1947). The higher the tolerance level of the handle (the smaller the number), the better the handle of the tool handle. The tighter the inner hole of the spindle is. The shank of Yipuhui's knife handle and the inner hole of the spindle are all AT3 or the bonding area is 85%. The tolerances of HSK knife handles are guaranteed to be manufactured in accordance with the tolerance range of DIN69893

2. Parts of clamping accuracy and repeatability:

Repeat accuracy: The repeatability of the tool holder refers to the amount of change in the clamping precision of each measurement when the tool is repeatedly disassembled or clamped.

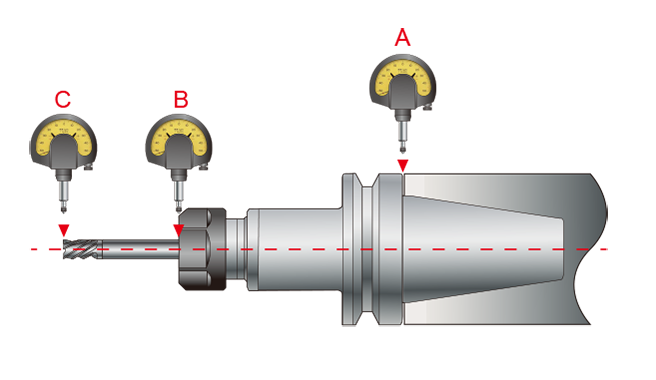

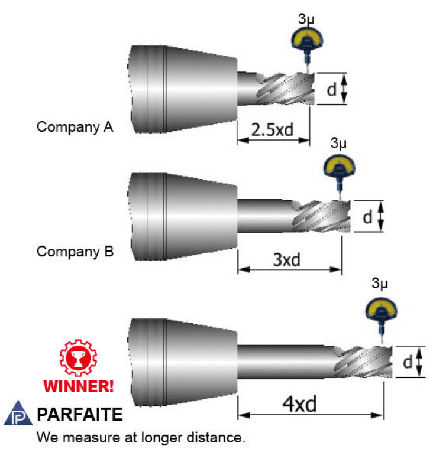

Clamping accuracy: The clamping accuracy of the tool holder refers to the deflection after the tool holder clamps the tool. The measurement method is to clamp the test rod and rotate it 360 degrees at several times the length of the shank diameter and measure its deflection.

Clamping accuracy and repeatabilityImportance to processing:

- Ensure workpiece surface roughness and machining accuracy

- Save the machining Time

- Protecting and Extending Tool Life

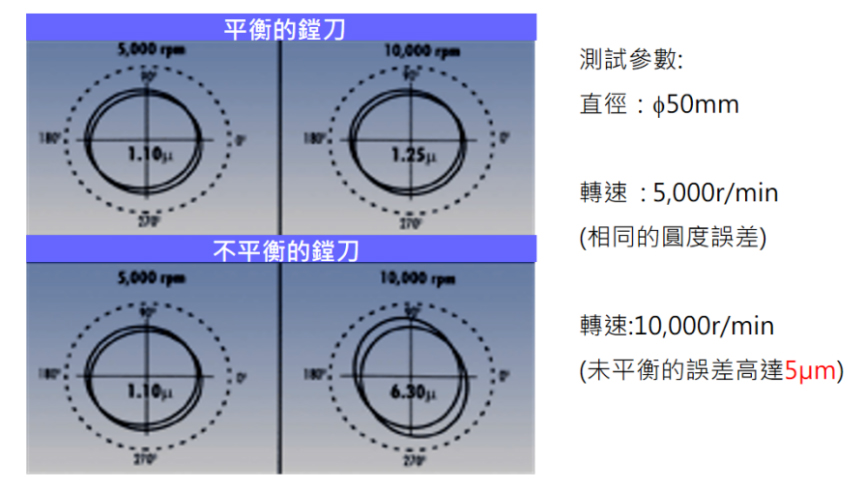

3.BALANCINGpart :

Dynamic balance has been listed as the most basic index to measure a qualified knife handle together with the precision of the handle. The source of imbalance in a tool holder is usually functional, for example it can be caused by a set screw in an end mill holder, or by unequal depth keyways in a tool holder. These causes often appear randomly without certain rules, so no matter what the situation is, the user must finally try to compensate this imbalance in order to achieve the purpose of dynamic balance correction.

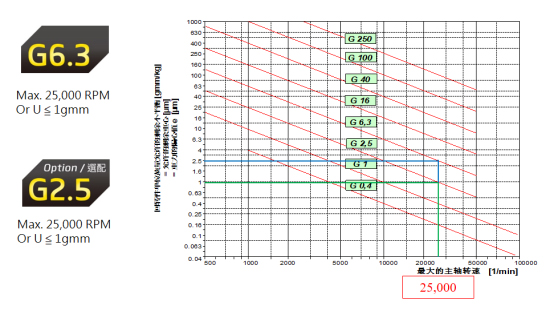

According to the ISO 1940 specification, the dynamic balance grade can be divided into 11 grades from G4,000 to G0.4. The lower the G number, the higher the dynamic balance level. G6.3 is the basic dynamic balance level of Puhui, and G2.5 is the optional level

Importance of choosing the right handle:

Right Tool for your job! It has always been our philosophy to choose the most suitable tool holder to complete the cutting plan according to different processes and conditions during processing.

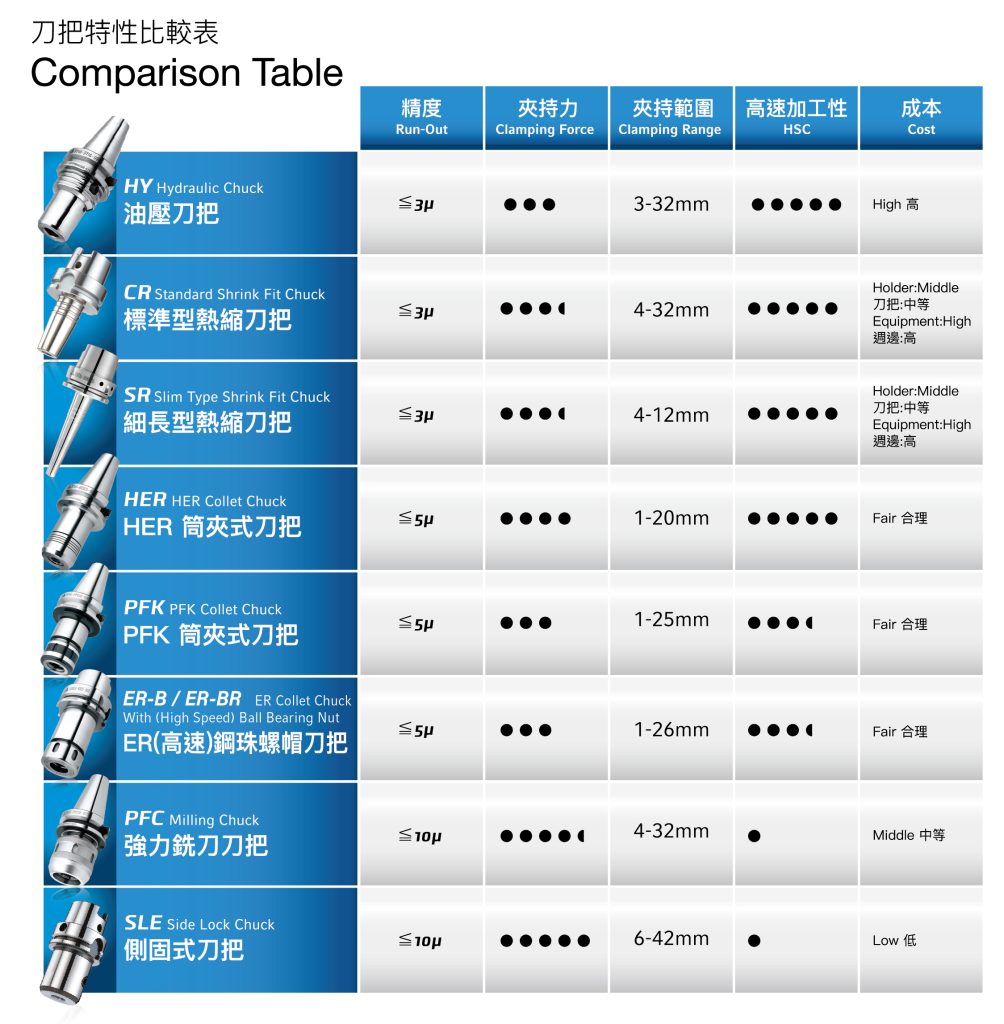

Below we will make a tool holder feature comparison table based on deflection accuracy, clamping force, clamping range, high-speed machining, and cost. Provide customers with a basic reference when choosing a knife handle