Customized composite cutting tools and RFID Tool Management make production more efficient

2022Taiwan Smart Manufacturing report-Taiwan Machine Tool Accessories:Powering Global Supply Chains with Smart Manufacturing

“ Precision is absolutely critical to the lifespan and efficiency of the cutting tool, as low runout can reduce tool wear”, explains William Wan , Vice General Manager at Parfaite.

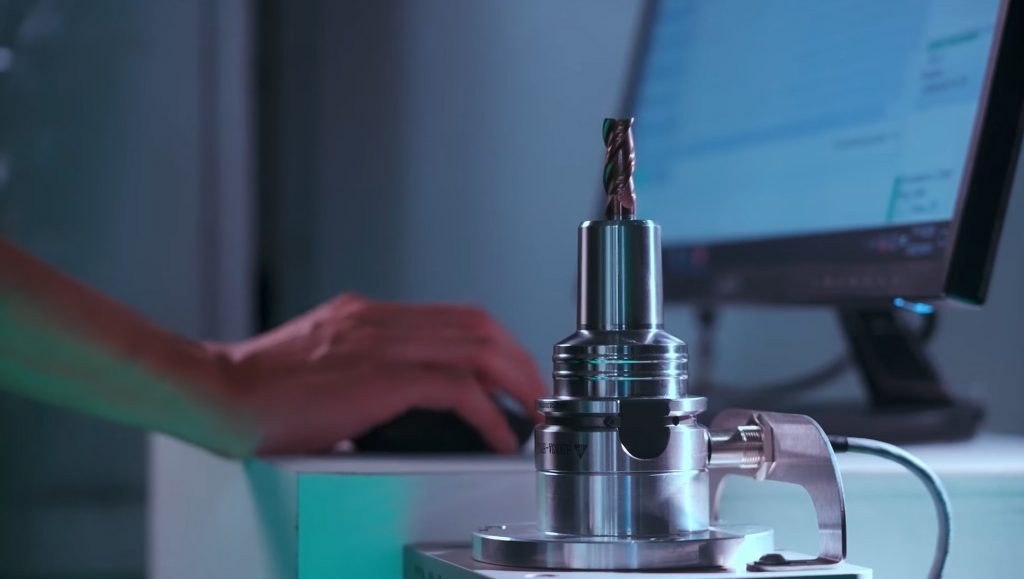

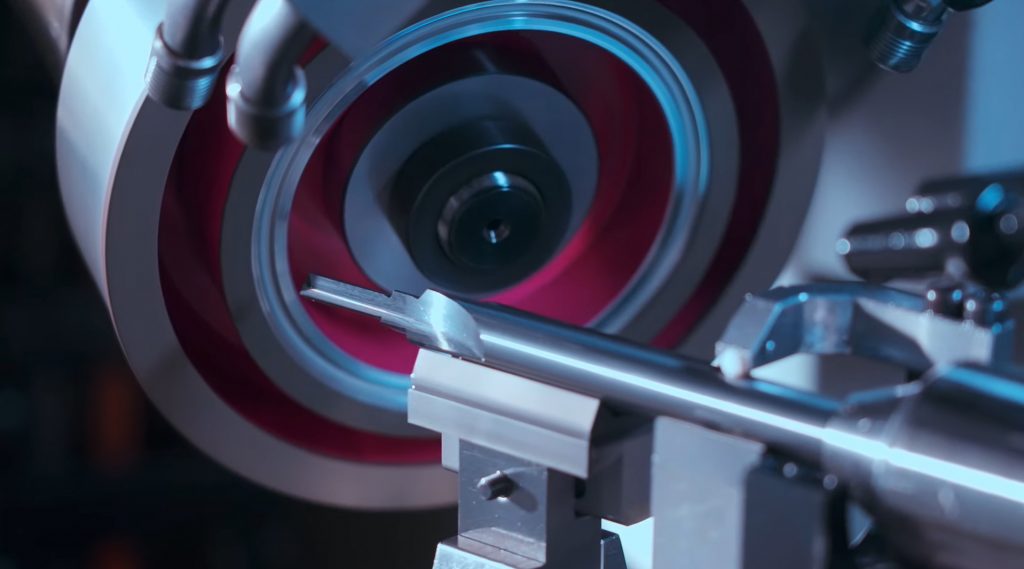

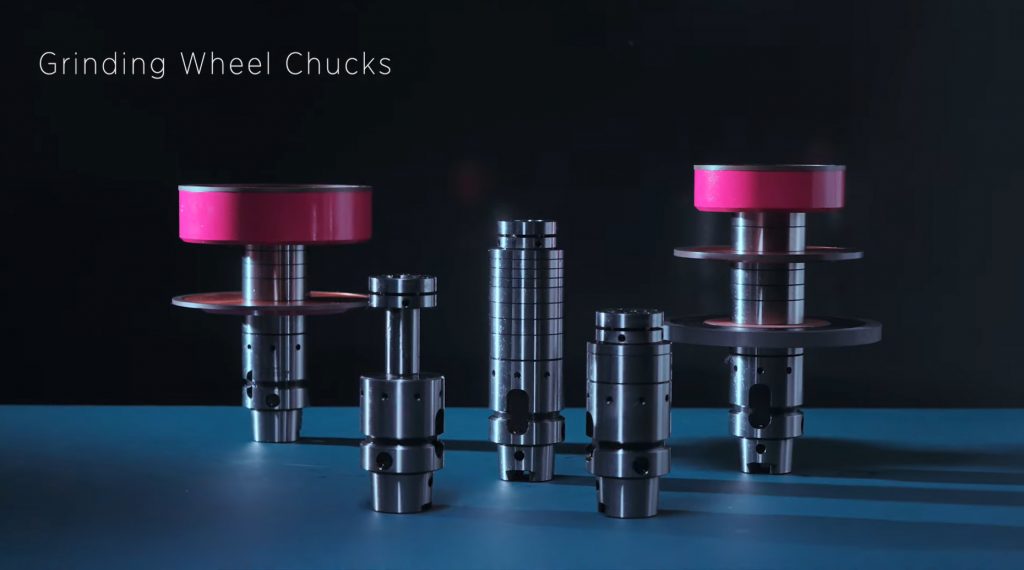

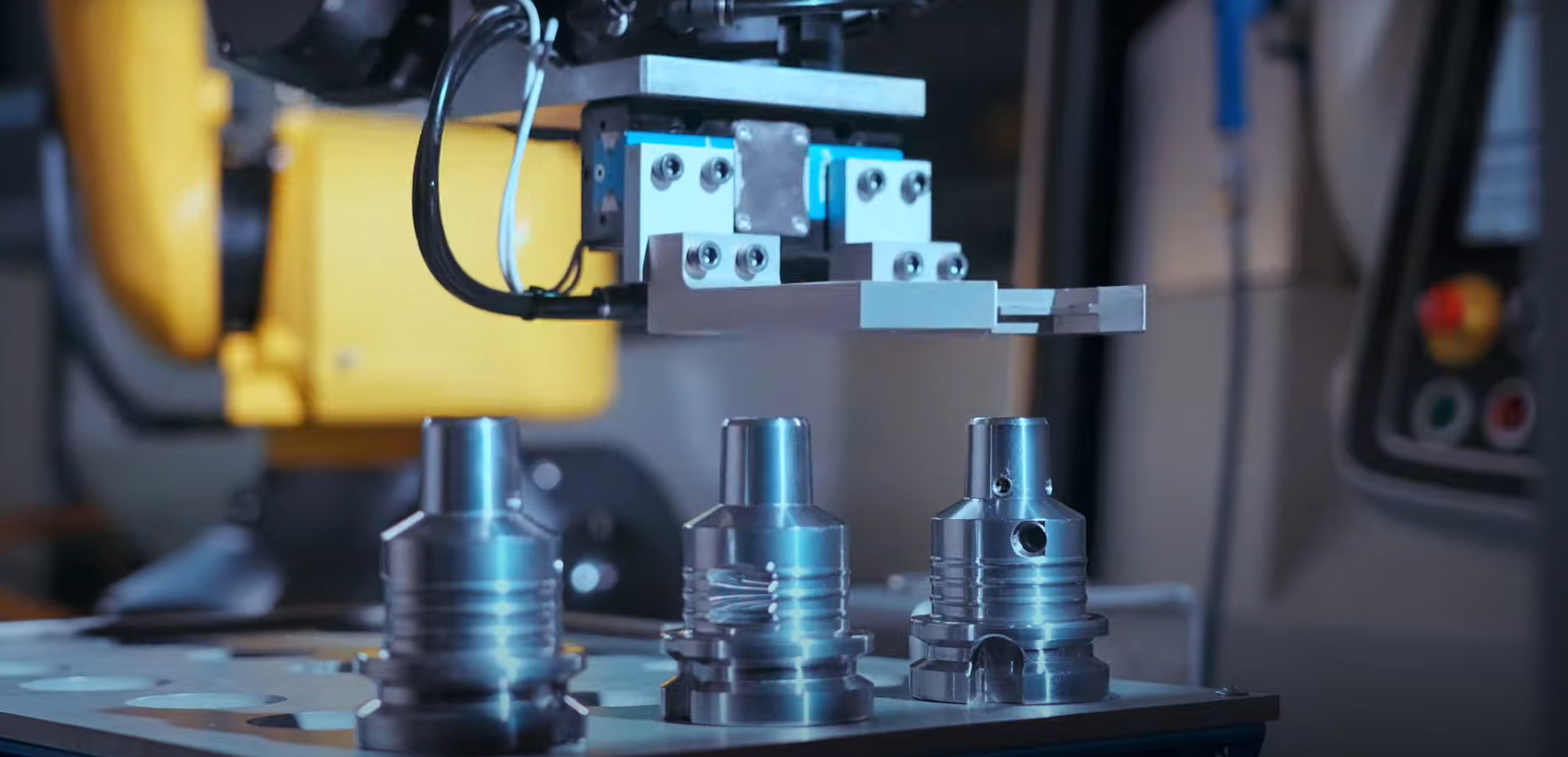

As one of the few professional manufacturers in the world that can produce and design high-speed built-in spindles, precision tool holders and forming tools, from the vibration-absorbing 3μmHydraulic Chuck, Slender type 3μmShrink Fit Chuck,High-speed and high-precision 5μm collet-type tool holder, grinding wheel tool handles, Puhui not only provides diversified high-end products, but also uses RFID combined with tool handles for integrated application of tool management. Before putting the tool on the machine, as long as the chip card is sensed on the tool handle, the working history and possible conditions of the tool can be known. loss level, bringing more intelligentTool life management, providing reliable support for the terminal processing process.

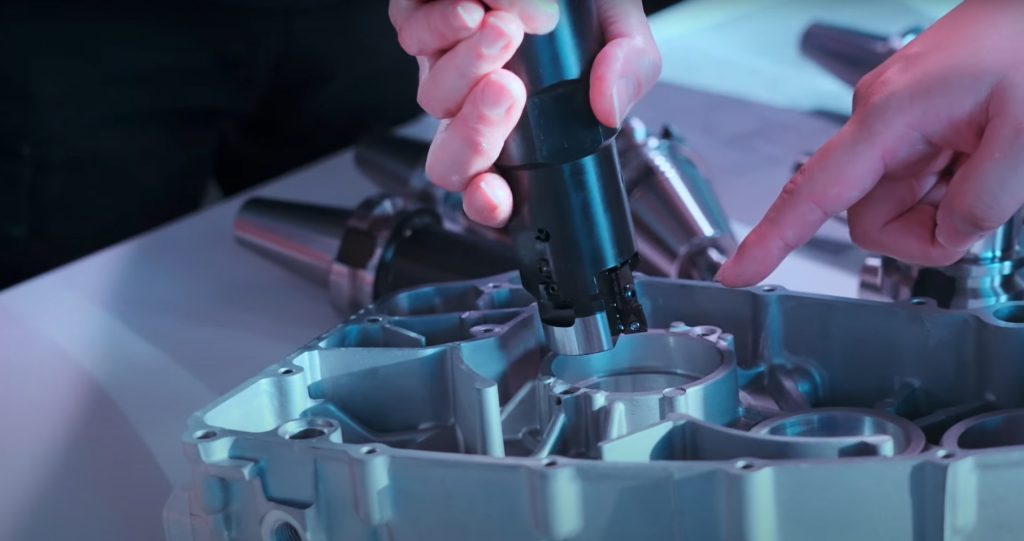

Over the years, Puhui has assisted customers in developing more than 100,000Customized knife handles and knives, constantly innovating and improving technology. Wan Zhonghong, Vice President of Puhui: "Based on customers' needs and usage habits, we can help design products that are more suitable and can improve efficiency, such as simplifying the processing process and designing molds for holes that originally require multiple cutting tools. Grouped composite tools can not only reduce the use of tools, but also improve the relative accuracy of processing.”

Taiwan Smart Manufacturing https://zh.twmt.tw/news/catalog